1) The document describes the internship of a civil engineering student at NMIT, Bengaluru working with XXXX Projects Pvt Ltd on construction of an apartment project called ACE Apartments.

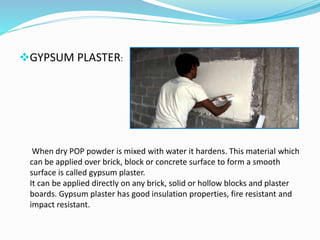

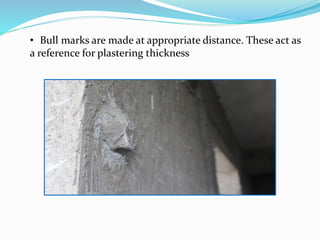

2) It provides details of the company, the site location, project timeline and costs. It also describes various construction activities observed like cement plastering and processes like customer modifications.

3) The conclusion expresses that the internship helped observe and learn construction procedures and created a link between theory and practice, which will benefit the student's future career.