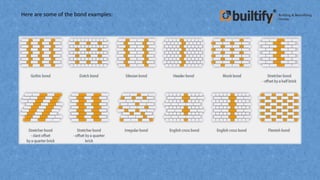

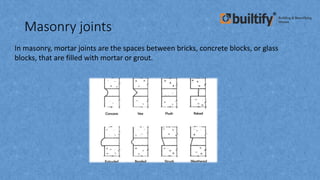

The document outlines the processes involved in brickwork and plastering, detailing the types of masonry, materials, tools, and techniques needed for proper construction. It emphasizes the importance of selecting quality bricks, adhering to systematic bonding practices, and ensuring proper curing and plastering methods. Additionally, it cites relevant Indian standards and provides a guide for achieving various plaster finishes.