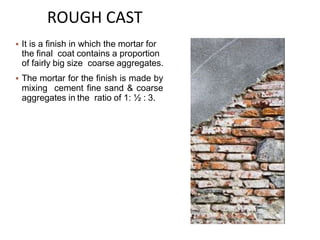

The document provides an overview of plastering, detailing its definition, objectives, materials, and methods. It emphasizes the properties of good plaster, types of plaster, and various finishing techniques, while also addressing common defects and prevention methods associated with plastering. Key tools used in the plastering process are also highlighted, along with guidelines for application thickness and coat layers.