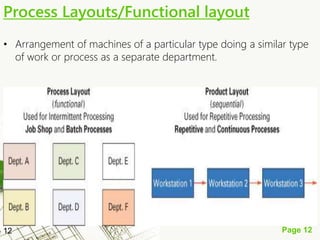

This document discusses different types of plant layouts used in manufacturing facilities. It describes product layouts as arranging machinery and materials following the product path for continuous or repetitive production processes. Process layouts group similar machinery into departments based on their function. Fixed-position layouts keep products stationary while moving workers and equipment. The document outlines factors to consider in layout design and provides examples of layouts used in pharmaceutical plants, including straight-line, side-by-side, and center storage designs. Plant layout configuration impacts efficiency, cost, flexibility and other operational aspects of production.