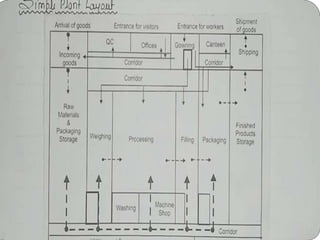

This document discusses the layout of a pharmaceutical plant. It describes two main types of plant layouts: process/functional layout and product/straight line layout. It also lists factors that influence plant layout decisions such as type of process, space availability, and health and safety considerations. The document provides details on storage space requirements for raw materials, finished goods, and specialized storage facilities. It concludes with a brief section on sterile or aseptic area layout in pharmaceutical plants.