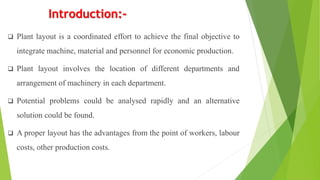

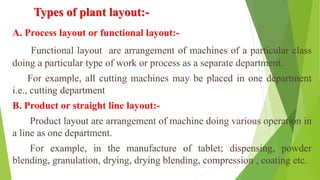

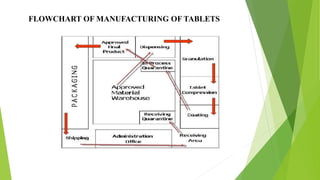

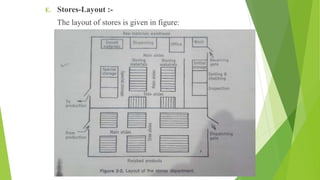

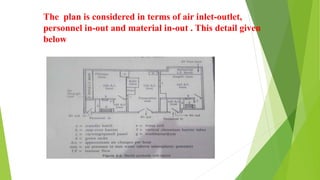

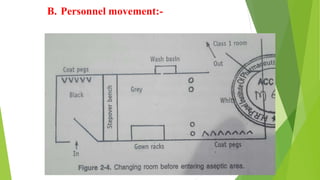

This document discusses plant layout for pharmaceutical manufacturing facilities. It begins by defining plant layout and its importance for efficient production. There are two main types of layouts: process/functional layout which groups similar machines together and product/straight line layout which arranges machines in the order of operations. Key factors that influence layout include the production process, available space, operational convenience, and regulatory requirements. Special provisions for pharmaceutical facilities include preventing confusion or contamination. Storage areas for raw materials and finished goods are also discussed, including specific storage requirements. The document concludes by outlining the layout of sterile or aseptic manufacturing areas which separate different operations and control air flow and personnel movement to maintain sterility.