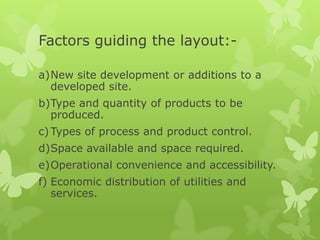

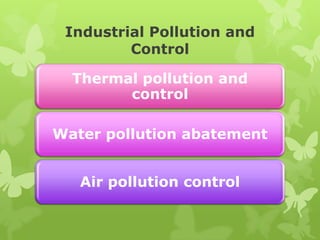

The document discusses factors to consider when selecting a plant location and designing the layout for a pharmaceutical formulation production facility. Key factors for location include raw materials, markets, energy/utilities, transportation, and labor. The plant layout should group similar processes together and allow for logical product flow. Utilities like power, water, waste disposal must also be properly planned to meet production needs. Overall plant location and layout are vital decisions that strongly influence business success.