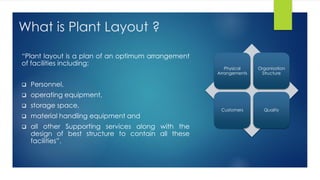

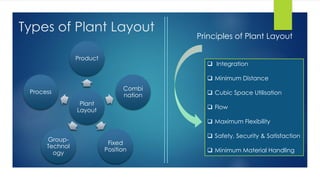

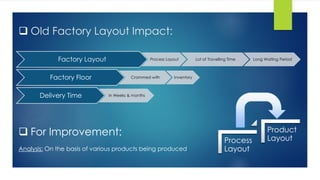

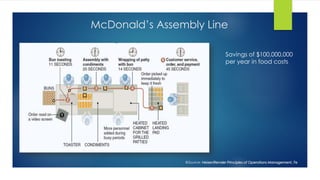

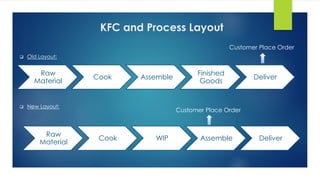

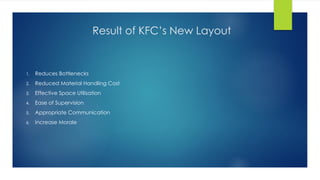

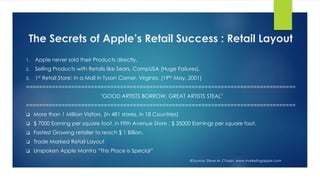

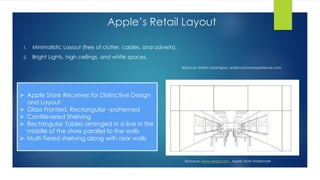

Plant layout refers to the arrangement of facilities including personnel, equipment, storage, and supporting services within a facility. This document discusses several case studies of plant layouts and principles of effective layout. It provides examples of how Taco and KFC optimized their layouts to reduce inventories, throughput times, and costs. Apple's retail layout is also examined, highlighting how its minimalist, bright design centered around product interaction has contributed to the company's retail success. Recent trends toward more open office designs and automated warehouses are also mentioned. In summary, plant layout significantly impacts operations and competitiveness by influencing efficiency, capacity, flexibility and other priorities.