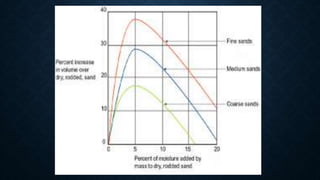

The document discusses various material failure mechanisms including necking, fatigue, yield point, roughness, bulking, wear, and tear. It defines necking as plastic flow that decreases the cross-sectional area when a material is loaded to its yield point. Fatigue is defined as weakening caused by repeated loads that can cause damage at stress levels below ultimate tensile strength. Yield point marks the transition from elastic to plastic behavior.