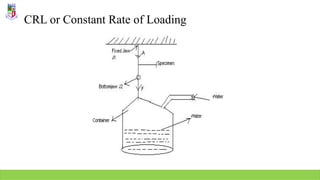

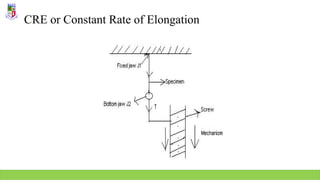

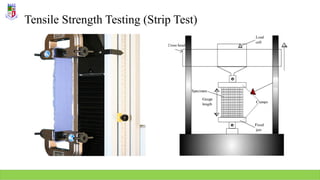

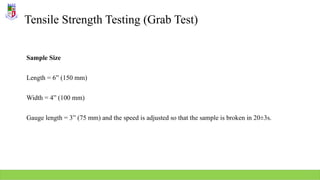

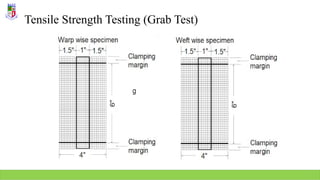

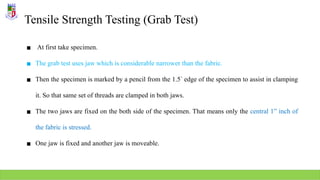

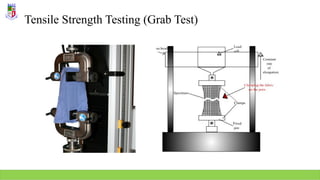

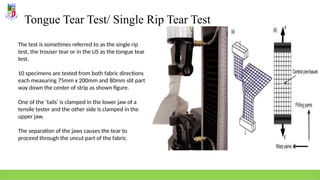

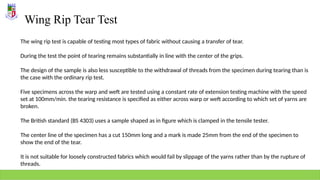

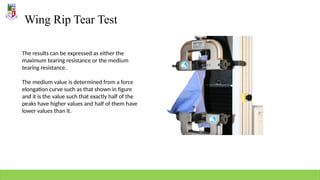

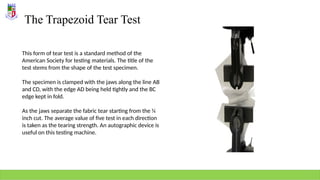

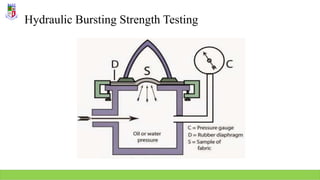

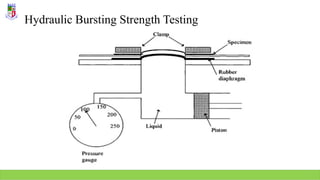

The document discusses various aspects of fabric strength, emphasizing its importance in preventing fabric failure under load. It covers types of tensile strength testing methods, including strip and grab tests, detailing procedures and factors impacting results. Additionally, it describes tearing and bursting strength tests, outlining the significance of these measures for evaluating fabric durability in different applications.