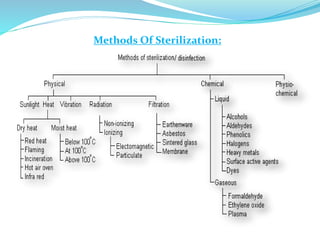

This document discusses various sterilization methods, including physical and chemical methods. Physical sterilization methods involve the use of heat, radiation, filtration, etc. to eliminate all life forms. Heat sterilization is one of the most common and reliable methods, and can be achieved through moist heat (e.g. autoclaving) or dry heat (e.g. hot air oven). Radiation sterilization uses ionizing radiation like gamma rays or X-rays to sterilize materials. The document provides details on the mechanisms, applications, and considerations of various physical sterilization techniques.

![HEAT:

Heat is considered to be most reliable method of sterilization

of articles that can withstand heat.

- acts by oxidative effects

Sunlight as the biggest source of heat is the oldest and

cheapest way of achieving partial sterilization of cloths.

- only bactericidal [kills only bacteria] in nature it is not

effective for a complete sterilization process.

- microbial activity of sunlight is due to the presence of UV

rays in it

- responsible for spontaneous sterilization by killing bacteria

suspended in water, provides natural method of disinfection of

water bodies such as tanks and lakes.](https://image.slidesharecdn.com/physicalsterlization-140426175249-phpapp02/85/Physical-sterlization-6-320.jpg)

![Hot Air Oven:

•This method was introduced by Louis Pasture.

•Articles to be sterilized are exposed to high temperature

[160°c] for duration of 1-2 hour in an electrically heated oven.

•Since air is poor conductor of heat, even distribution of heat

throughout the chamber is achieved by a fan.

•The heat is transferred to the article by radiation,

conduction and convection.](https://image.slidesharecdn.com/physicalsterlization-140426175249-phpapp02/85/Physical-sterlization-22-320.jpg)

![• Consist of three walls and a door made of gun metal that

insulate and keep the heat in and conserves energy, the inner

layer being a poor conductor and outer layer being metallic.

-air filled space in between to aid insulation.

• An air circulating fan helps in uniform distribution of the heat.

• These are fitted with the adjustable wire mesh plated trays or

aluminum trays and may have an on/off rocker switch, as well as

indicators [thermostat] and controls for temperature and

holding time](https://image.slidesharecdn.com/physicalsterlization-140426175249-phpapp02/85/Physical-sterlization-23-320.jpg)

![Sterilization Control:

• Three methods exist to check the efficacy of sterilization

process, namely physical chemical and biological.

Physical – Temperature chart recorder and thermocouple.

Chemical – Browne’s tube No.3 [green spot, color changes

from red to green]

Biological – 10^6 spores of Bacillus subtilis or Clostridium

tetani on paper strips are placed inside the hot air oven.

After sterilization cycle, the strips are inoculated into

thioglycollate broth or cooked meat medium and incubated at

37°c for 3-5 days.

Proper sterilization NO GROWTH](https://image.slidesharecdn.com/physicalsterlization-140426175249-phpapp02/85/Physical-sterlization-27-320.jpg)

![At temperature below 100°c:

Pasteurization:

•This process was originally employed by Louis Pasteur.

•Currently this procedure is employed in food and dairy

industry.

• There are two methods of pasteurization,

holder method [heated at 63°c for 30 minutes]

flash method [heated at 72°c for 15sec.] followed by quickly

cooling to 13°c.](https://image.slidesharecdn.com/physicalsterlization-140426175249-phpapp02/85/Physical-sterlization-30-320.jpg)

![• Other pasteurization method include Ultra-High

temperature [UHT], 140°c for 15sec and 149°c for .5sec.

•This method is suitable to destroy most milk borne

pathogens like Salmonella, Mycobacteria, and

Streptococoi.

Efficacy is tested by phosphatase test and methylene

blue test.](https://image.slidesharecdn.com/physicalsterlization-140426175249-phpapp02/85/Physical-sterlization-31-320.jpg)

![Advantage of Steam:

• more penetrative power than dry air

• moistens the spores [moister is essential for

coagulation of proteins],](https://image.slidesharecdn.com/physicalsterlization-140426175249-phpapp02/85/Physical-sterlization-35-320.jpg)

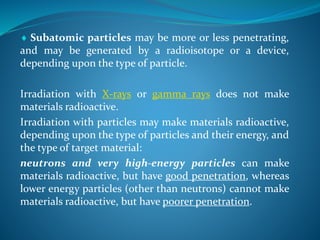

![• Energy transmitted through space in a variety of forms is generally

called Radiation.

•Electromagnetic radiation can interact with matter in one of 2

general ways:

IONIZING RADIATIONS [X-ray and Y-rays]

NON-IONIZING RADIATION [UV light]](https://image.slidesharecdn.com/physicalsterlization-140426175249-phpapp02/85/Physical-sterlization-46-320.jpg)

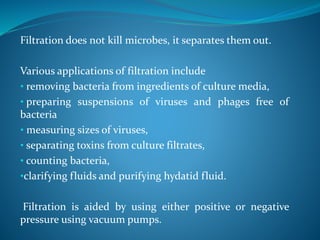

![When ingredients of a culture medium are thermolabile. i.e.,

destroyed by heat, the use of heat sterilization is not

practicable.

In such cases, however, the process of filtration is used.

[biological fluids such as solutions of antibiotics, vitamins,

tissue extracts, animal serum, etc.]](https://image.slidesharecdn.com/physicalsterlization-140426175249-phpapp02/85/Physical-sterlization-54-320.jpg)

![HEPA Filter:

High- Efficiency Particulate Air [HEPA]

Filter has made it possible to deliver clean air

to an enclosure such as a cubicle or a room.

This type of air filtration together with a

system of Laminar Airflow is now extensively

used to produce dust and bacteria free air](https://image.slidesharecdn.com/physicalsterlization-140426175249-phpapp02/85/Physical-sterlization-61-320.jpg)

![Temperature below the optimum for growth depresses the rate

of metabolism, and if the temperature is sufficiently low, growth

and metabolism ceases.

Low temperature is useful for preservation of cultures, since

microorganism have a unique capacity for surviving extreme

cold. [-20 -70°c]

Liquid Nitrogen at a temperature of -196°c is used for

preserving cultures

In all these procedures, the initial freezing kills a fraction of

population, but the survivors may remain viable for long

periods.](https://image.slidesharecdn.com/physicalsterlization-140426175249-phpapp02/85/Physical-sterlization-63-320.jpg)