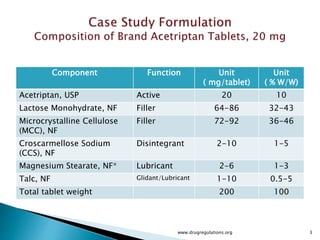

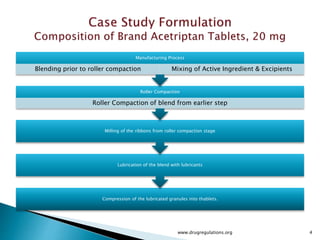

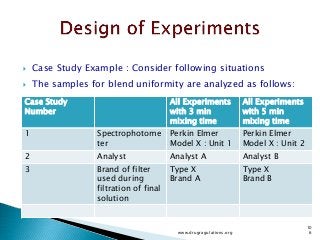

This document provides information about a case study on the blending process for a pharmaceutical formulation. It includes:

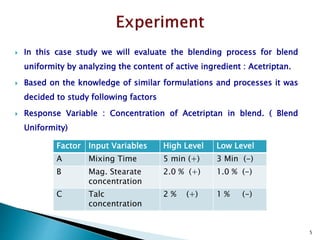

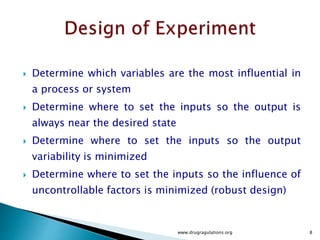

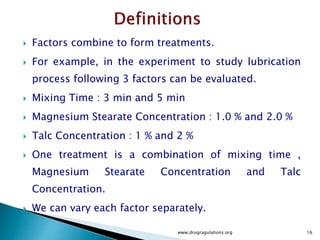

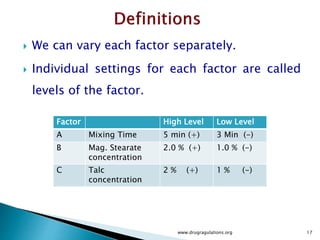

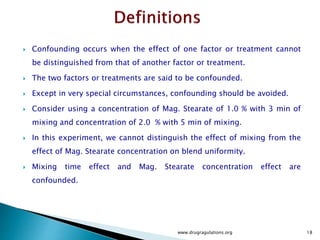

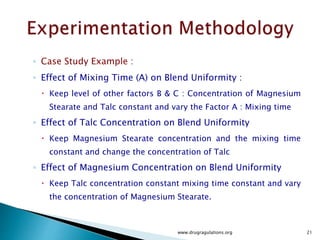

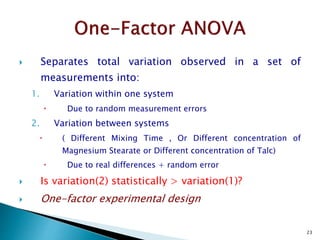

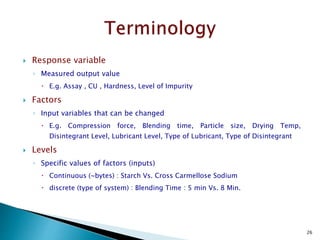

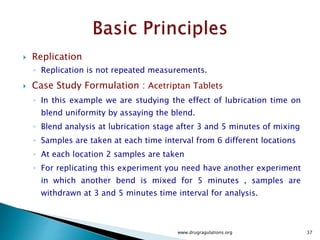

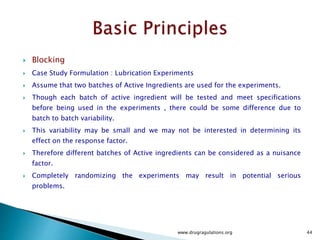

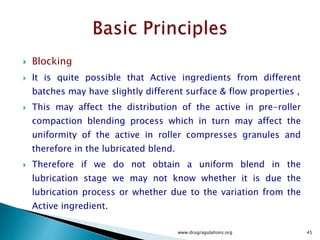

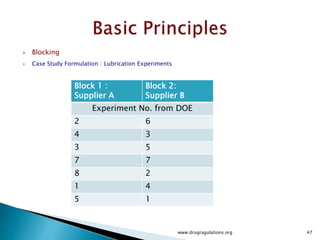

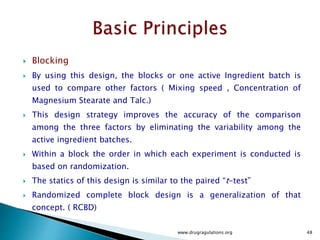

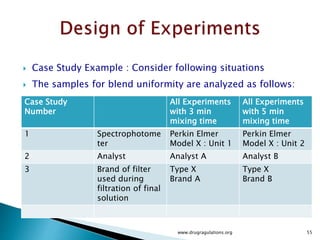

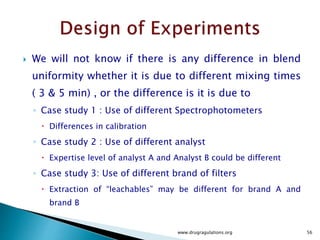

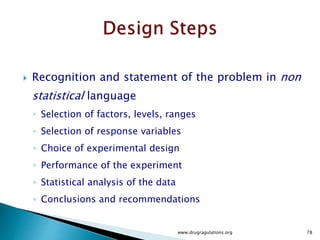

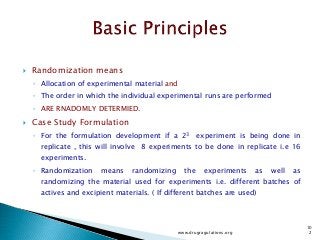

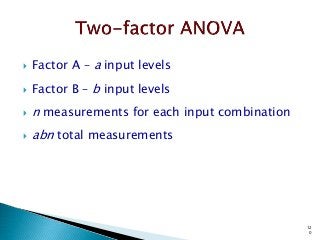

1) Details of the formulation and factors being studied (mixing time, magnesium stearate concentration, and talc concentration) to evaluate blend uniformity.

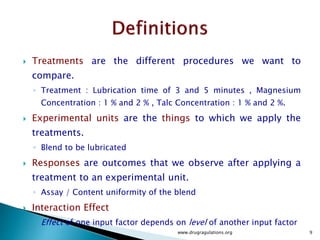

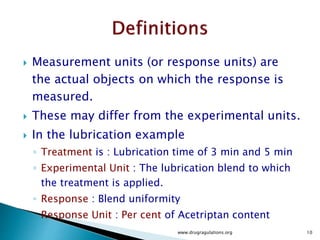

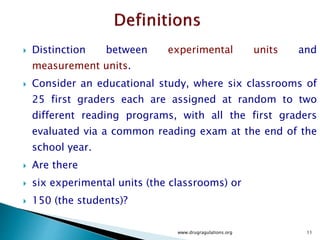

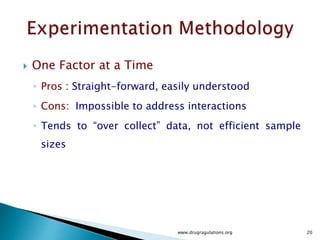

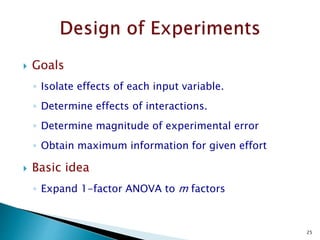

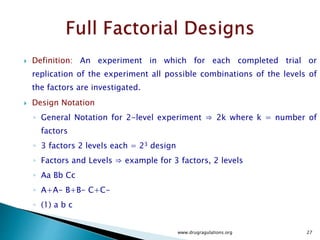

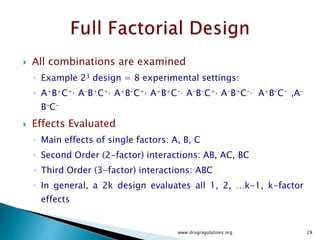

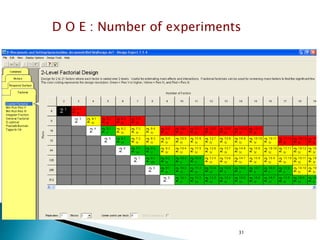

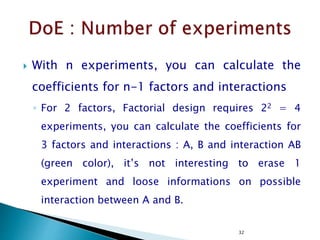

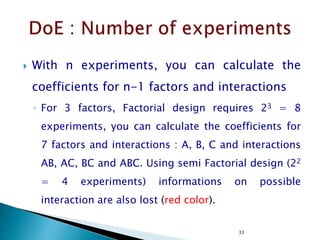

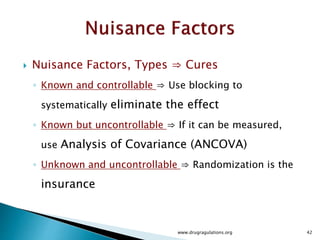

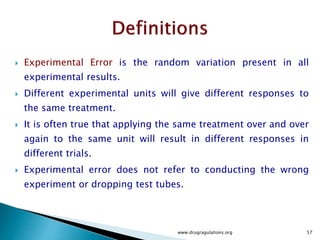

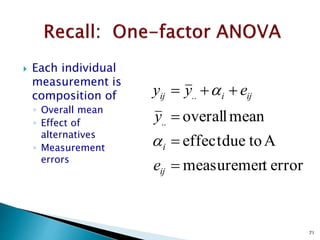

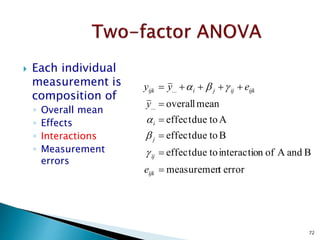

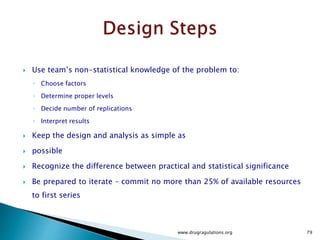

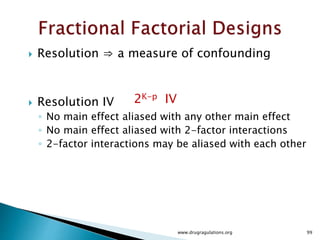

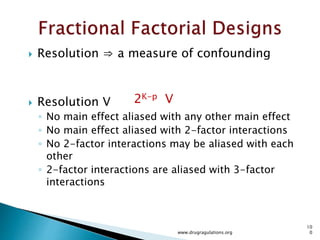

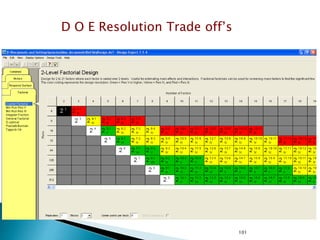

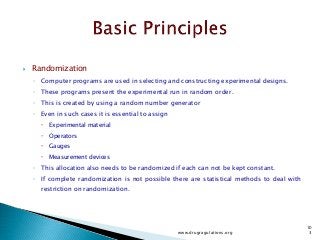

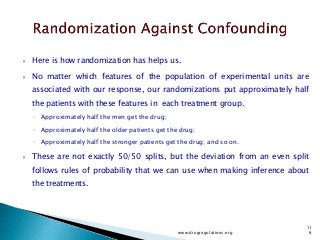

2) Descriptions of key concepts for experimental design including treatments, experimental units, responses, and interactions.

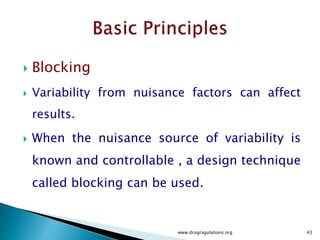

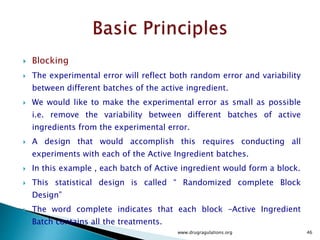

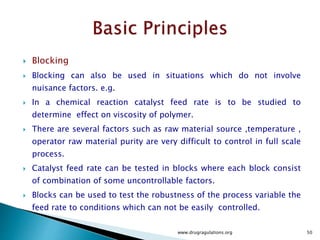

3) Discussion of blocking as a technique to reduce nuisance factors like different batches of active ingredients being studied.

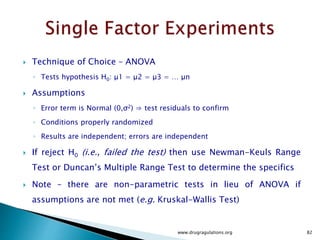

![30

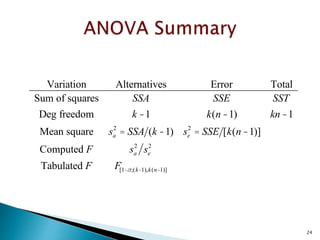

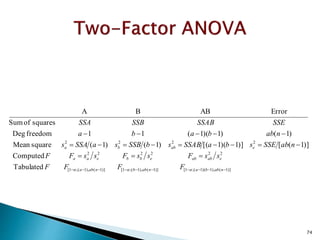

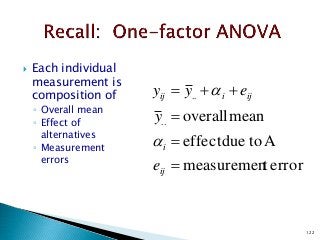

Variation Alternatives Error Total

Sum of squares SSA SSE SST

Deg freedom k -1 k(n -1) kn -1

Mean square sa

2

= SSA (k -1) se

2

= SSE [k(n -1)]

Computed F sa

2

se

2

Tabulated F F[1-a;(k-1),k(n-1)]](https://image.slidesharecdn.com/designofexperimetsforbegginers-150814095059-lva1-app6892/85/Pharmaceutical-Design-of-Experiments-for-Beginners-30-320.jpg)

![12

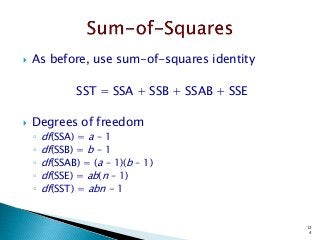

5

)]1(),1)(1(;1[)]1(),1(;1[)]1(),1(;1[

222222

2222

Tabulated

Computed

)]1([)]1)(1[()1()1(squareMean

)1()1)(1(11freedomDeg

squaresofSum

ErrorABBA

nabbanabbnaba

eababebbeaa

eabba

FFFF

ssFssFssFF

nabSSEsbaSSABsbSSBsaSSAs

nabbaba

SSESSABSSBSSA

](https://image.slidesharecdn.com/designofexperimetsforbegginers-150814095059-lva1-app6892/85/Pharmaceutical-Design-of-Experiments-for-Beginners-125-320.jpg)