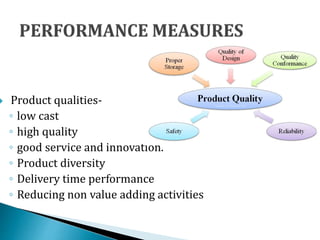

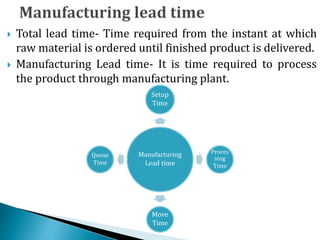

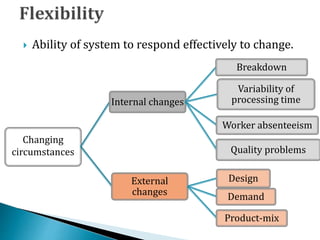

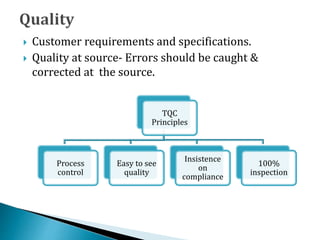

The document discusses various aspects of manufacturing efficiency, including product qualities, lead times, and machine utilization. It emphasizes the importance of effective resource utilization, quality control, and the ability to adapt to changes in production. Additionally, it highlights the significance of throughput and investment in work-in-progress (WIP) for optimizing production performance.