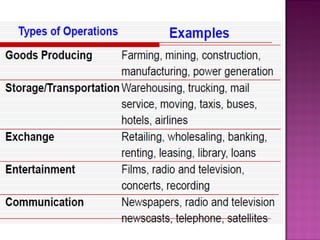

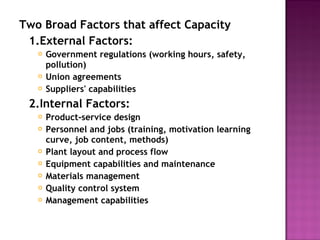

This document discusses production and operations management (POM). It defines POM as the management of direct resources, also called the 5 Ps - people, plant, parts, processes, and planning & control systems. POM lies at the heart of business activities and its ultimate objective is to produce a specified product on schedule at minimum cost. POM decisions are classified as strategic, operating, and control decisions. The document also discusses productivity measurement, factors affecting productivity, and the relationship between operations and marketing.