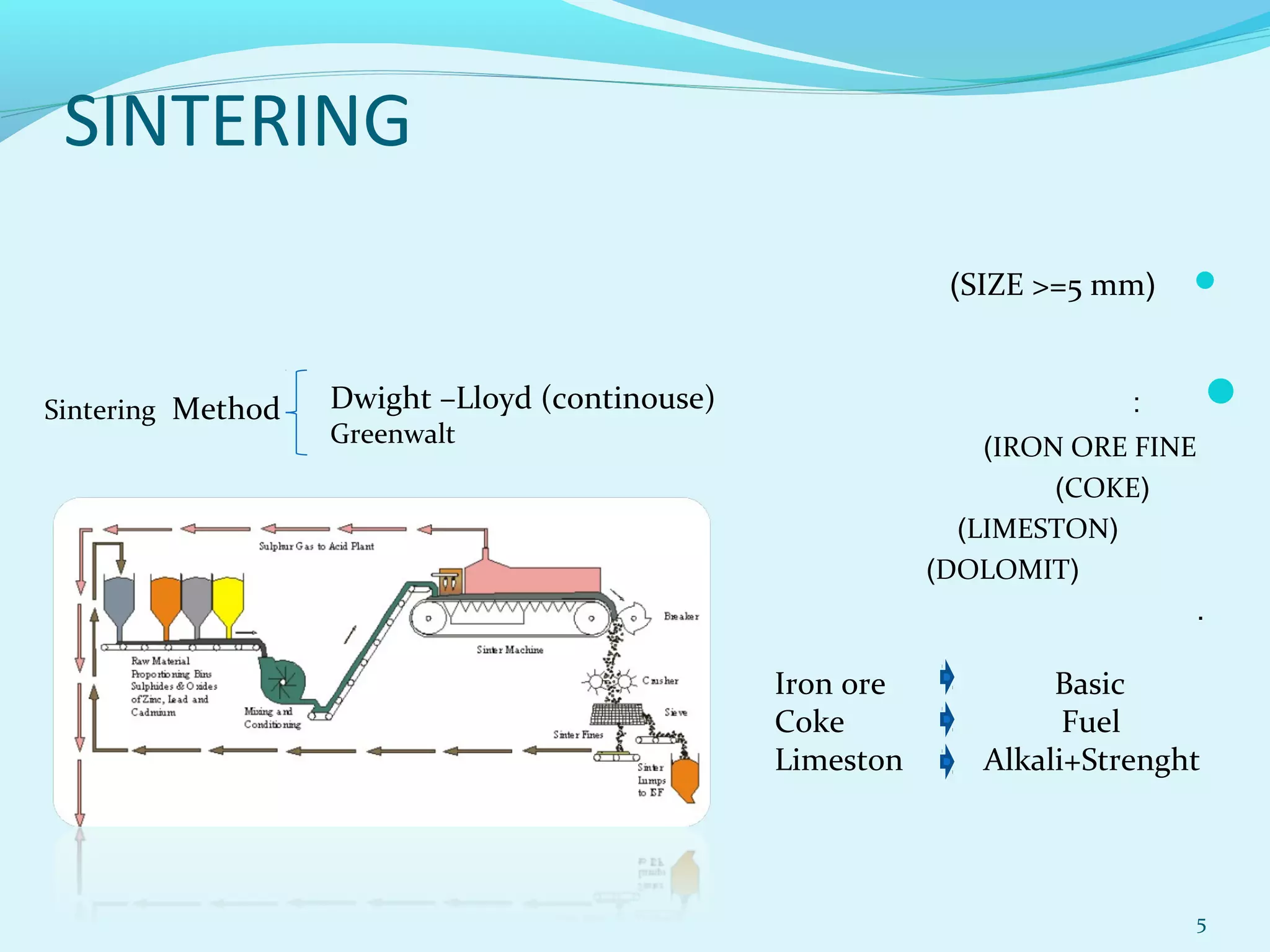

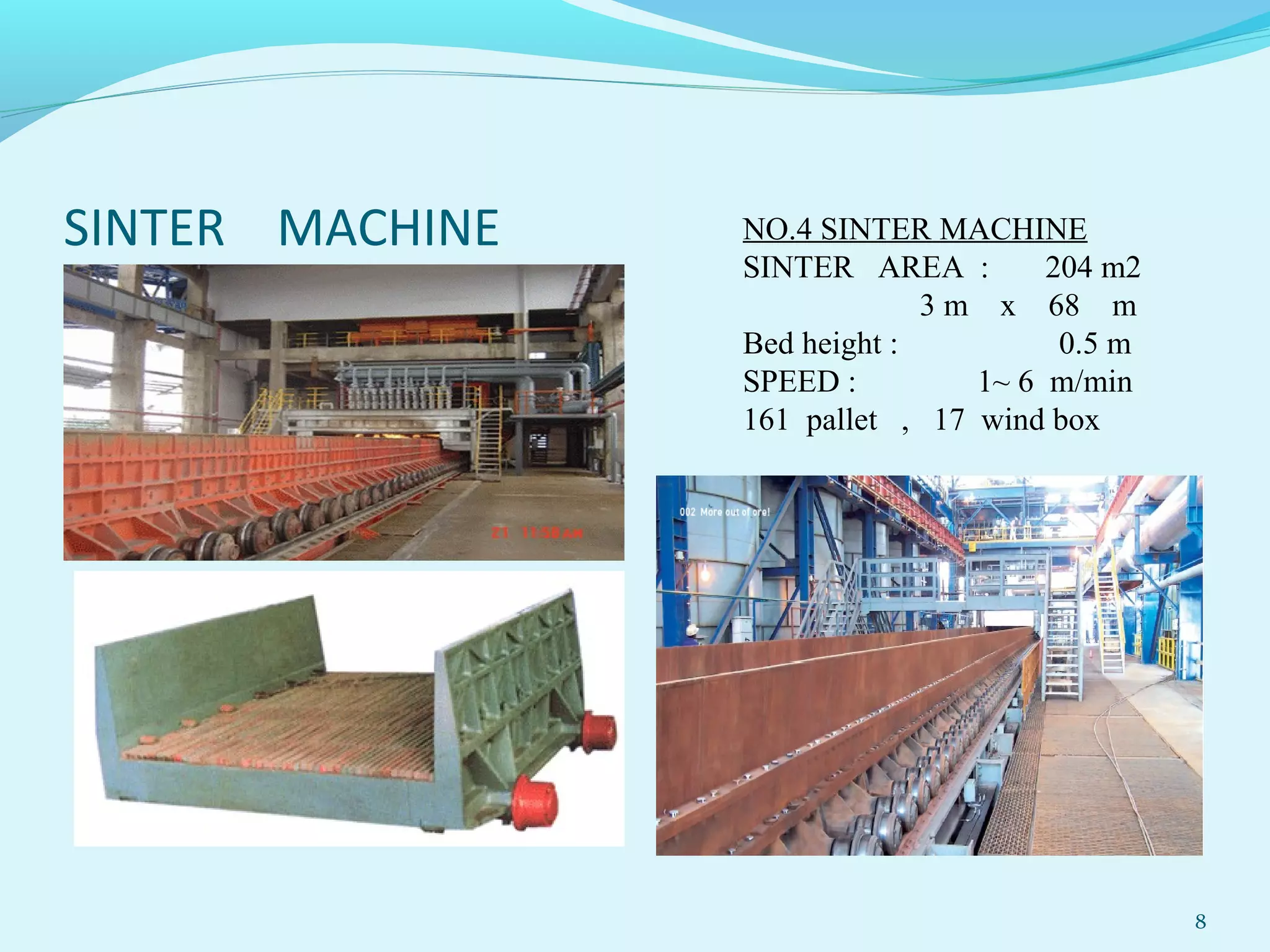

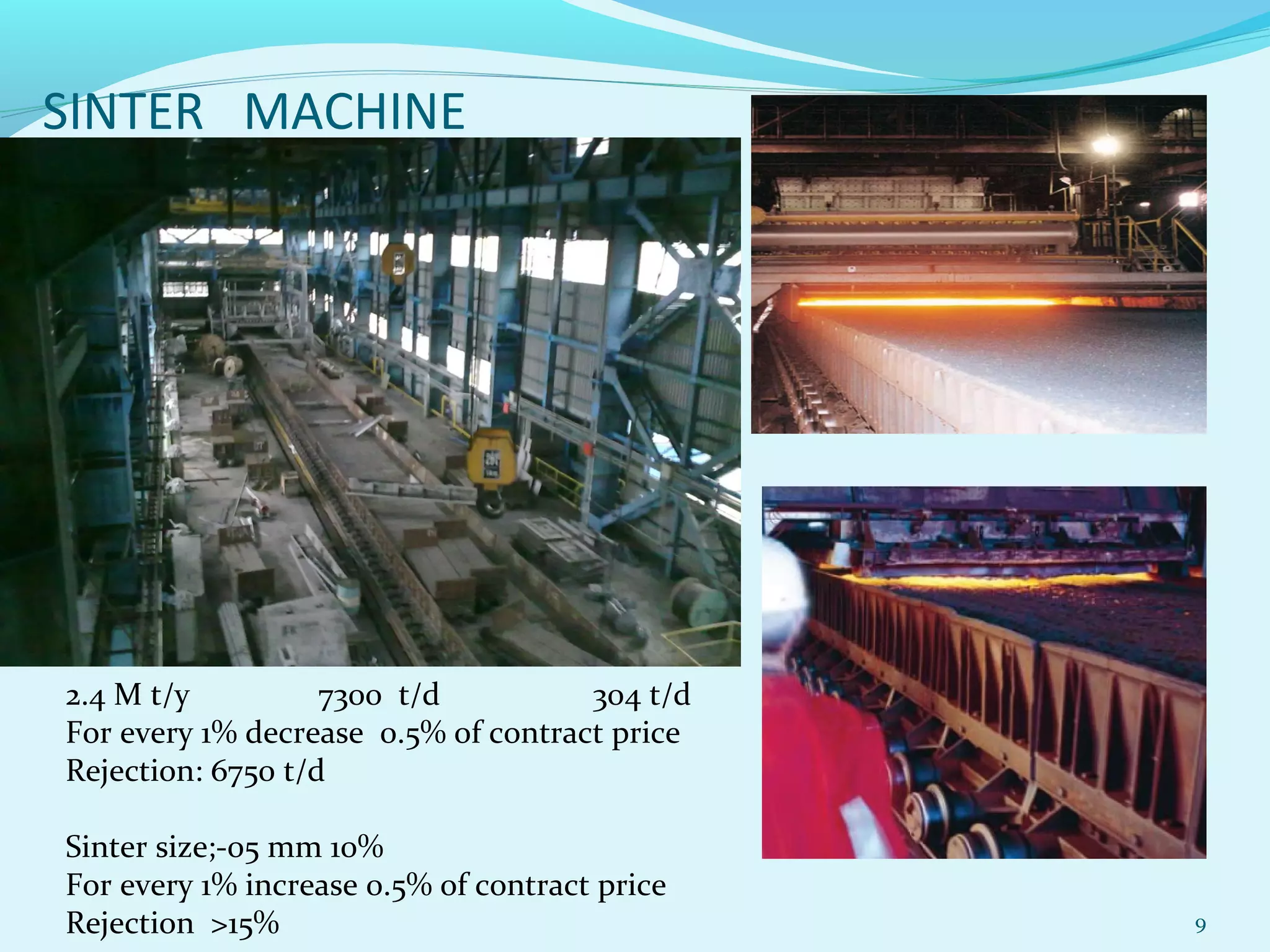

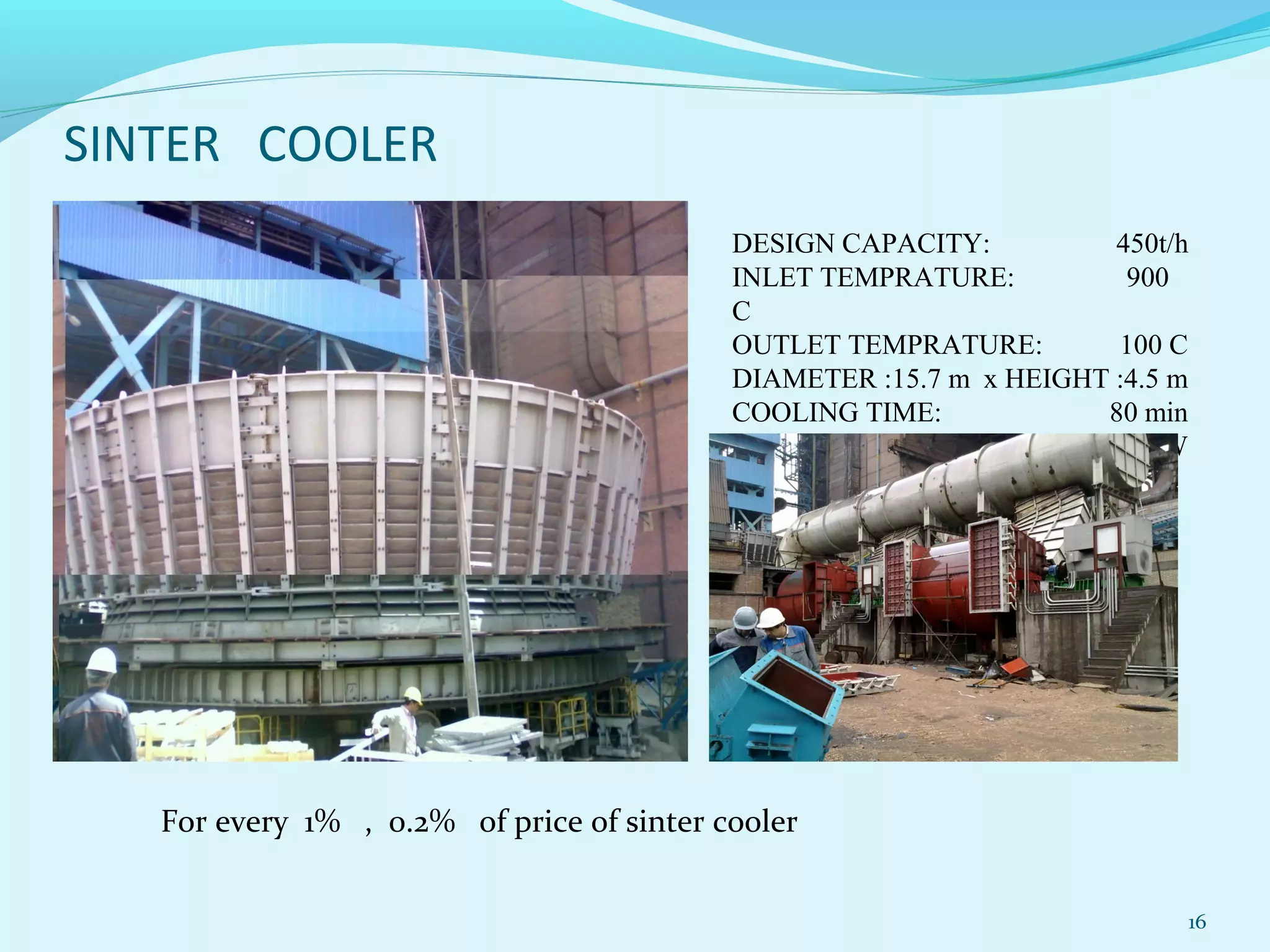

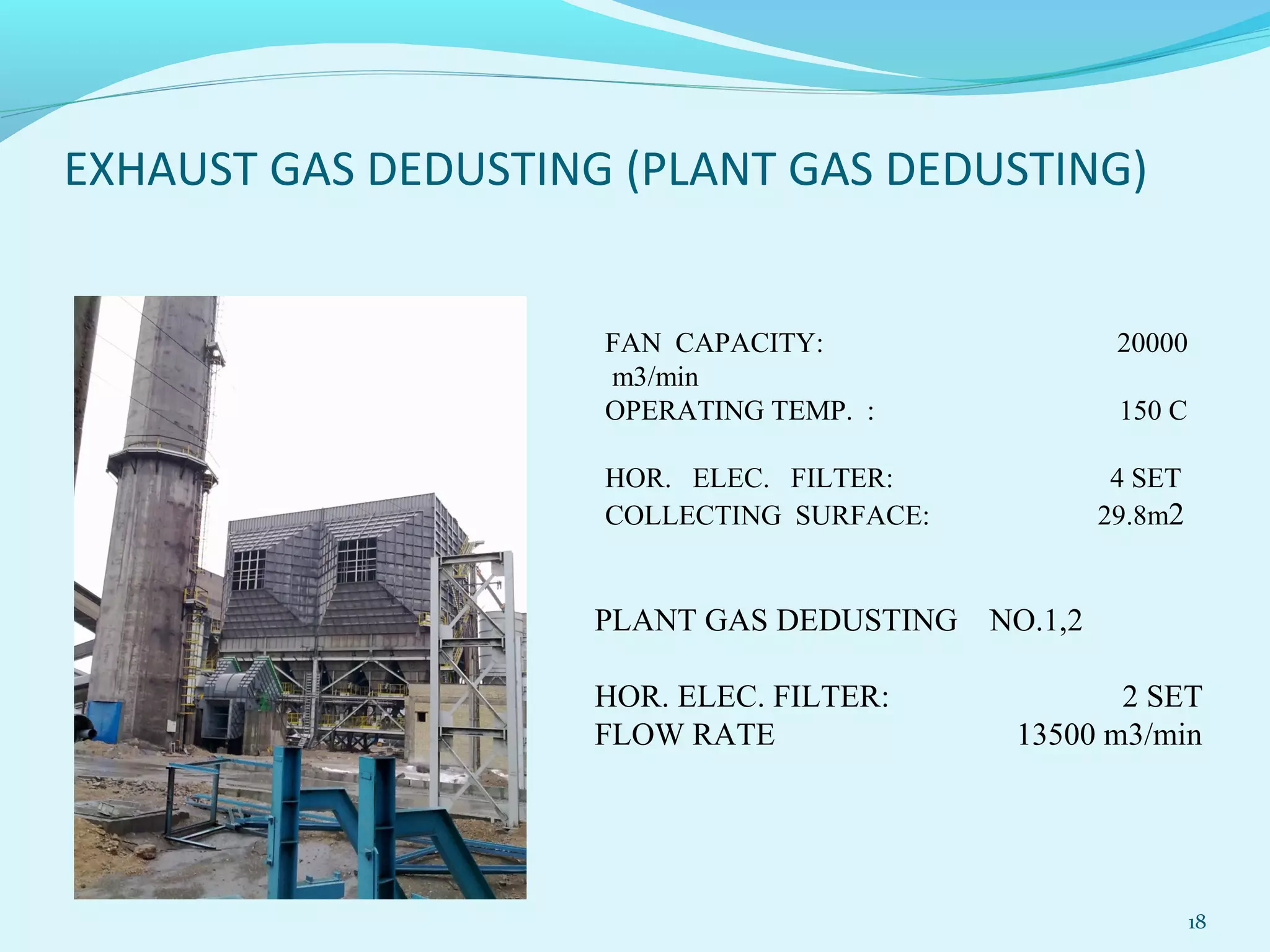

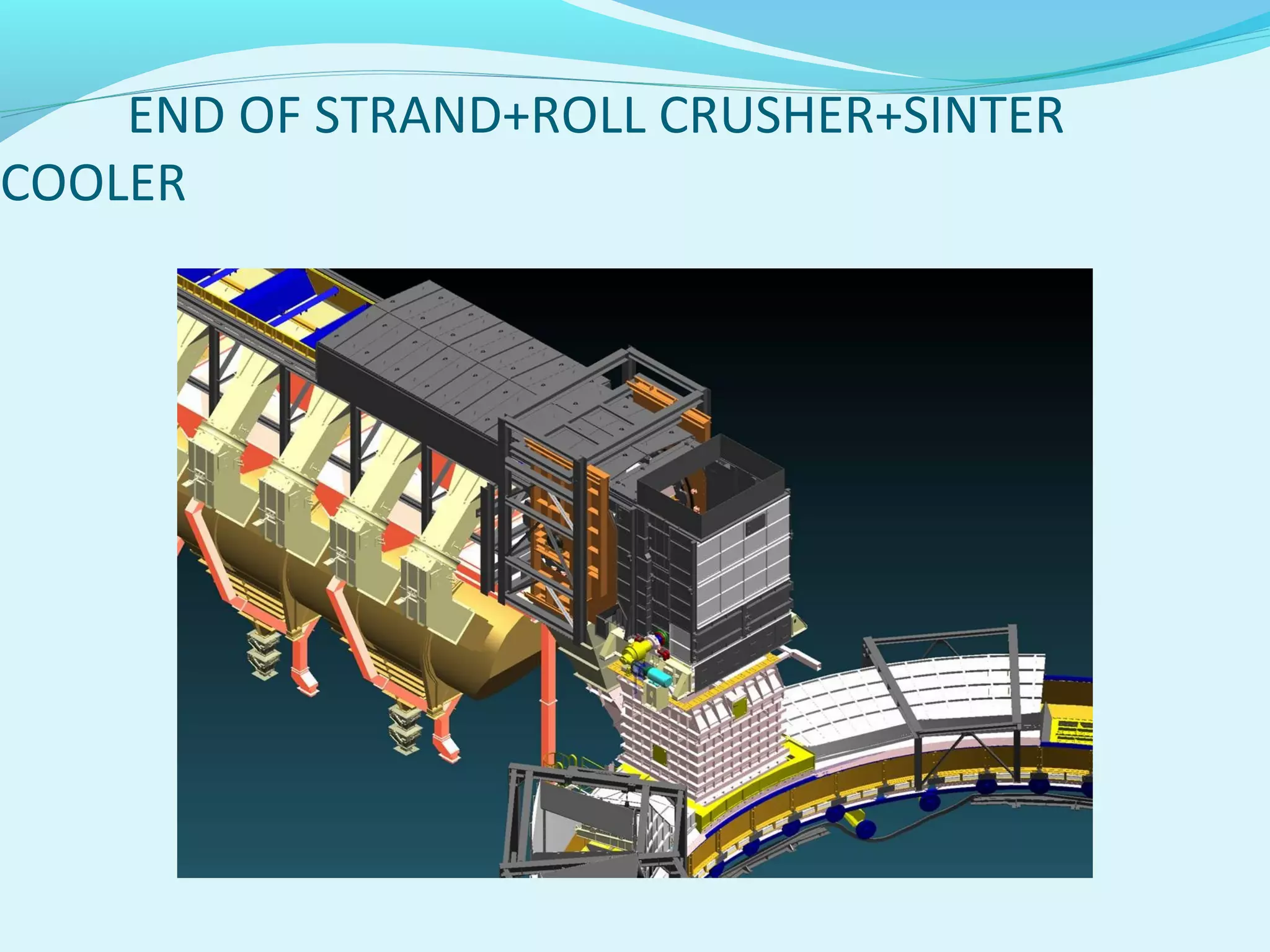

The document discusses the sintering process and equipment used in steel manufacturing, detailing various methods such as the Dwight-Lloyd continuous sintering method and the components of sintering plants. It provides insights into the mechanical and operational aspects of sintering machines, including their design, capacity, and cooling processes. Additionally, it highlights the significance of material composition and production percentages in the overall steelmaking process.