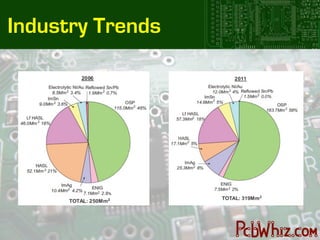

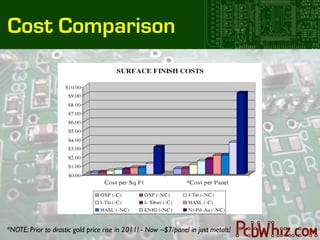

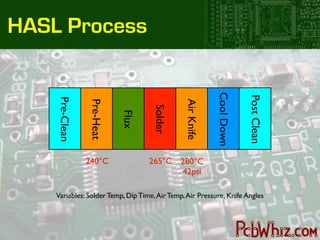

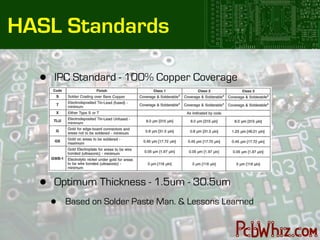

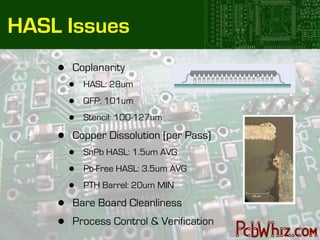

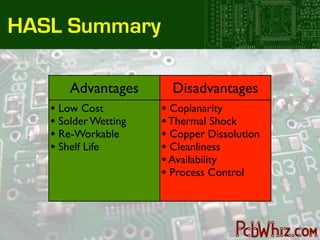

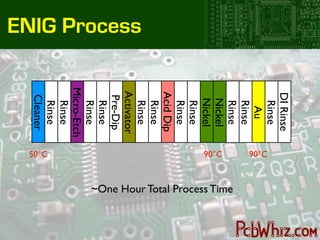

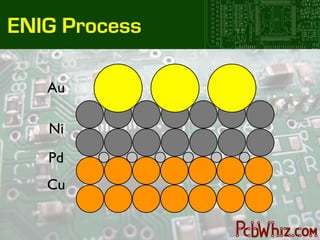

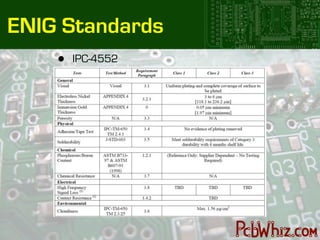

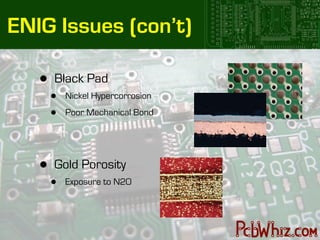

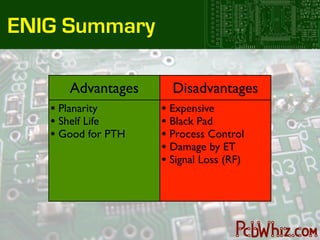

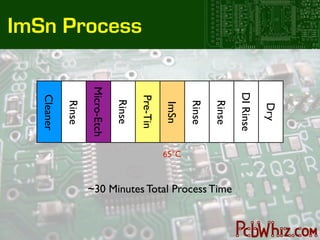

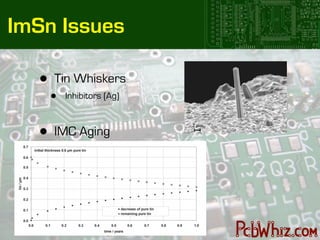

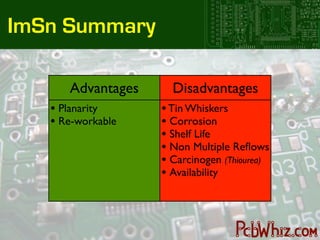

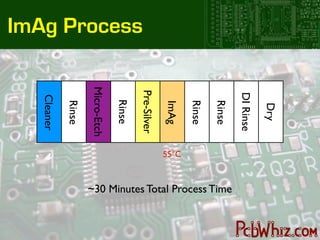

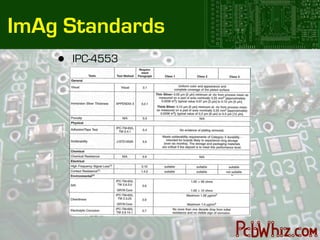

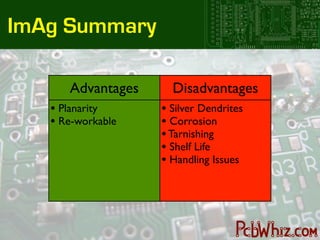

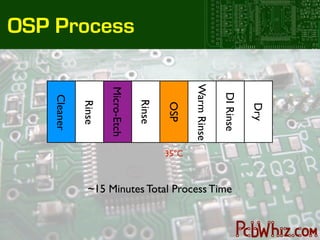

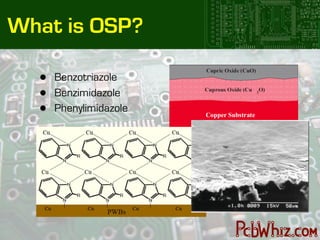

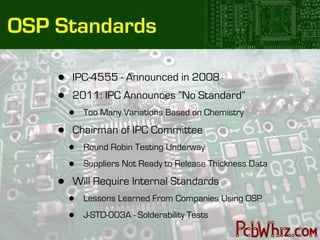

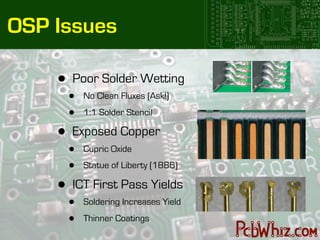

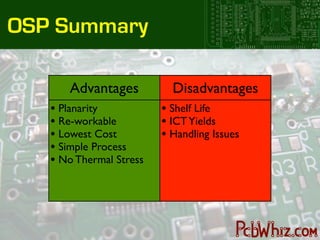

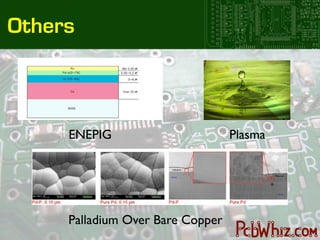

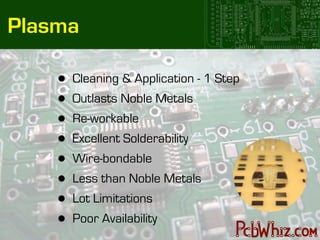

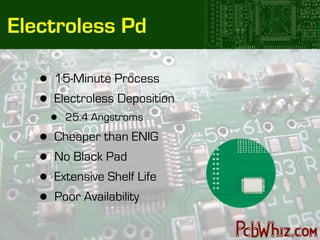

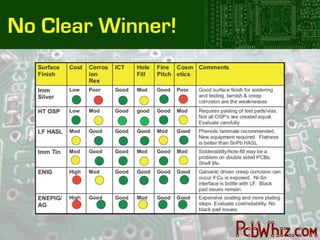

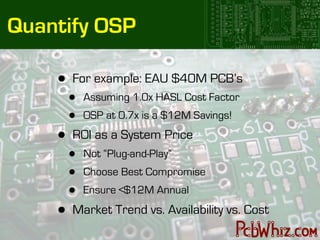

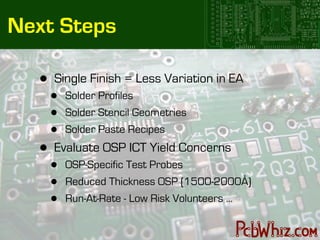

The document discusses various PCB surface finishes in a lead-free environment, including HASL, ENIG, IMSN, IMAG, and OSP, highlighting their advantages, disadvantages, and industry standards. It emphasizes factors influencing the choice of finishes such as cost, product volume, and reliability while addressing ongoing market trends and testing results. The conclusion indicates a need for further evaluation of surface finishes to optimize performance and cost-effectiveness in PCB manufacturing.