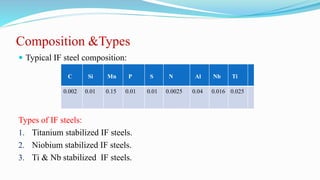

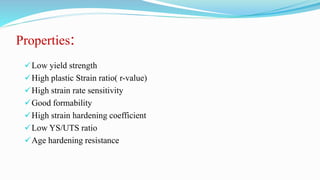

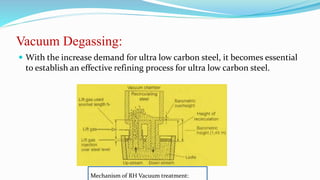

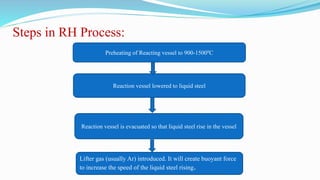

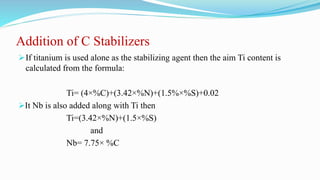

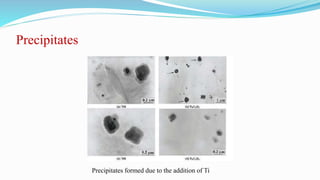

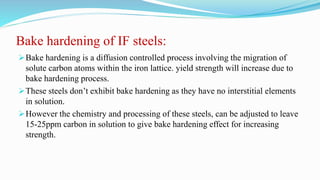

Interstitial free (IF) steels were developed in Japan in 1970. They contain very low amounts of carbon (below 30 ppm) due to the addition of stabilizing elements like titanium and niobium that form carbides. This allows for high plasticity and formability. IF steels are used in automotive body parts and deep drawn household appliances due to their low yield strength to tensile strength ratio and ability to be deeply drawn. They are produced through vacuum degassing and stabilization to remove interstitial atoms from the iron lattice.