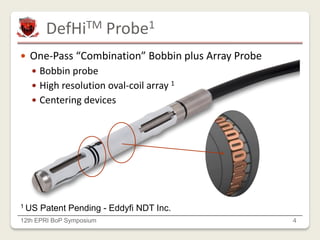

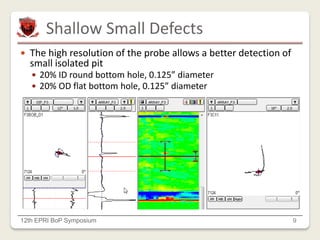

The document discusses the inspection of non-ferrous heat exchanger tubes using a combination of an eddy current array and bobbin probe. This technology addresses limitations of traditional methods by allowing high-resolution inspections in a single pass, detecting various defects with improved sensitivity and reliability. Key benefits include effective characterization of flaws and enhanced detection of circumferential cracking.