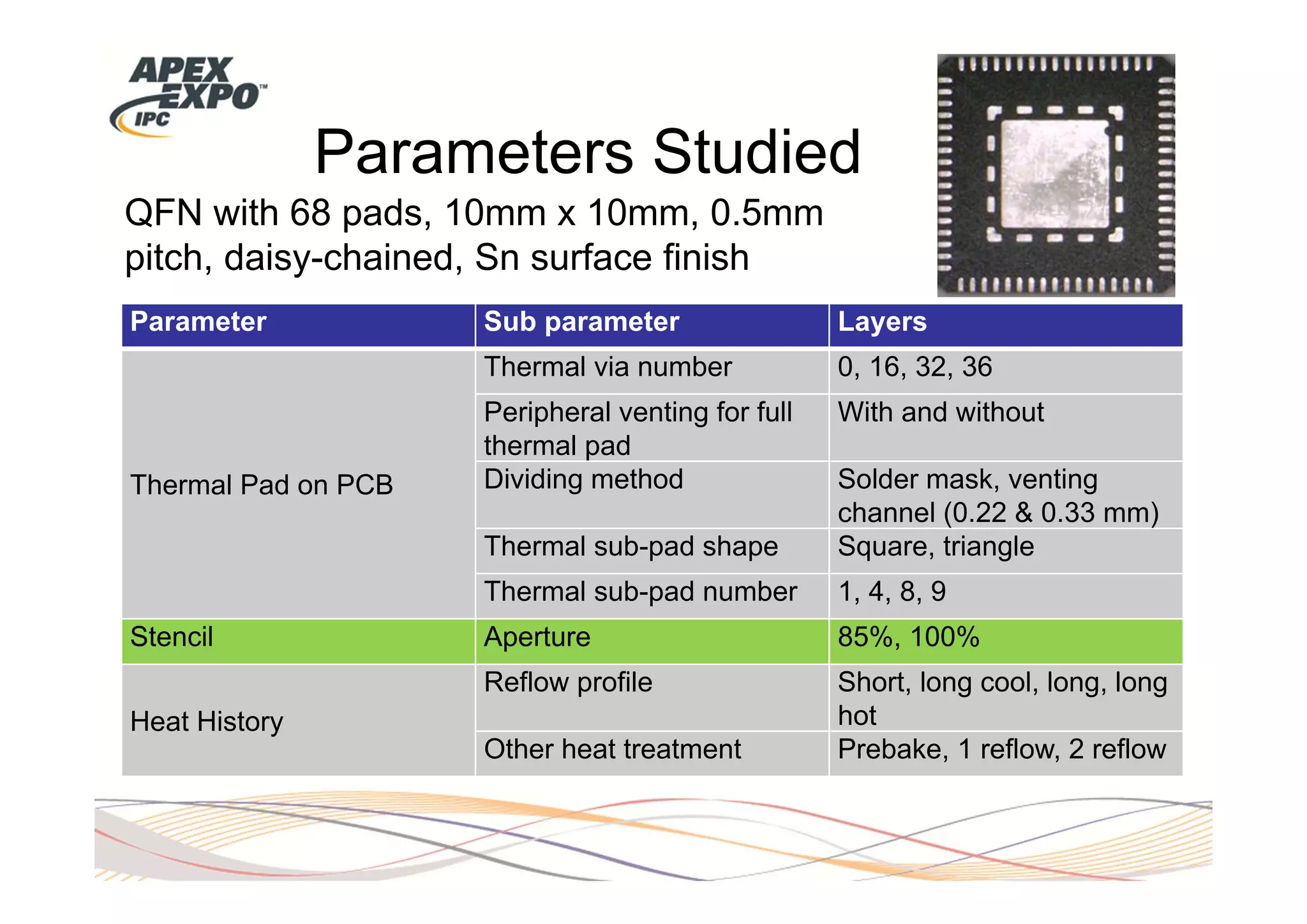

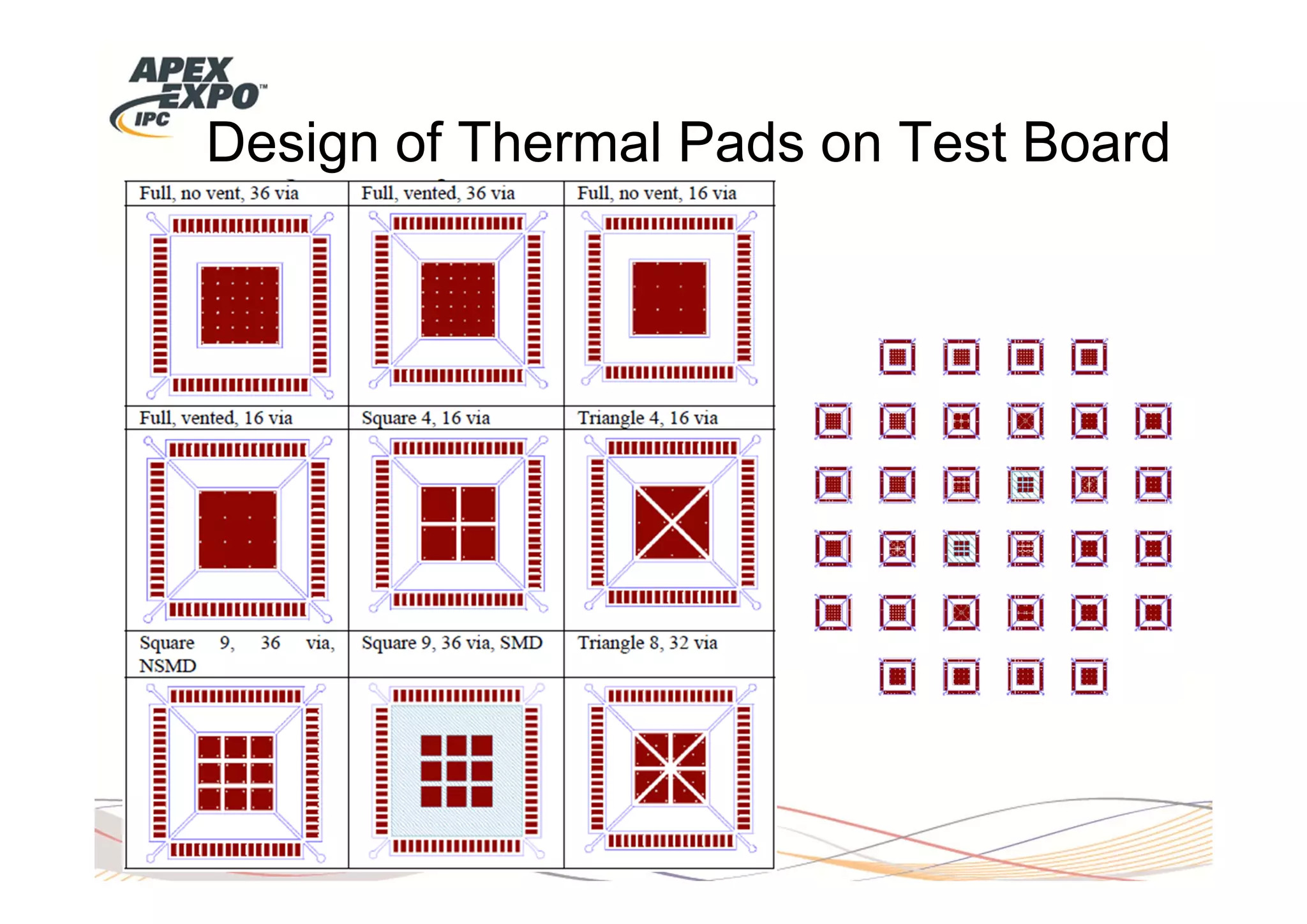

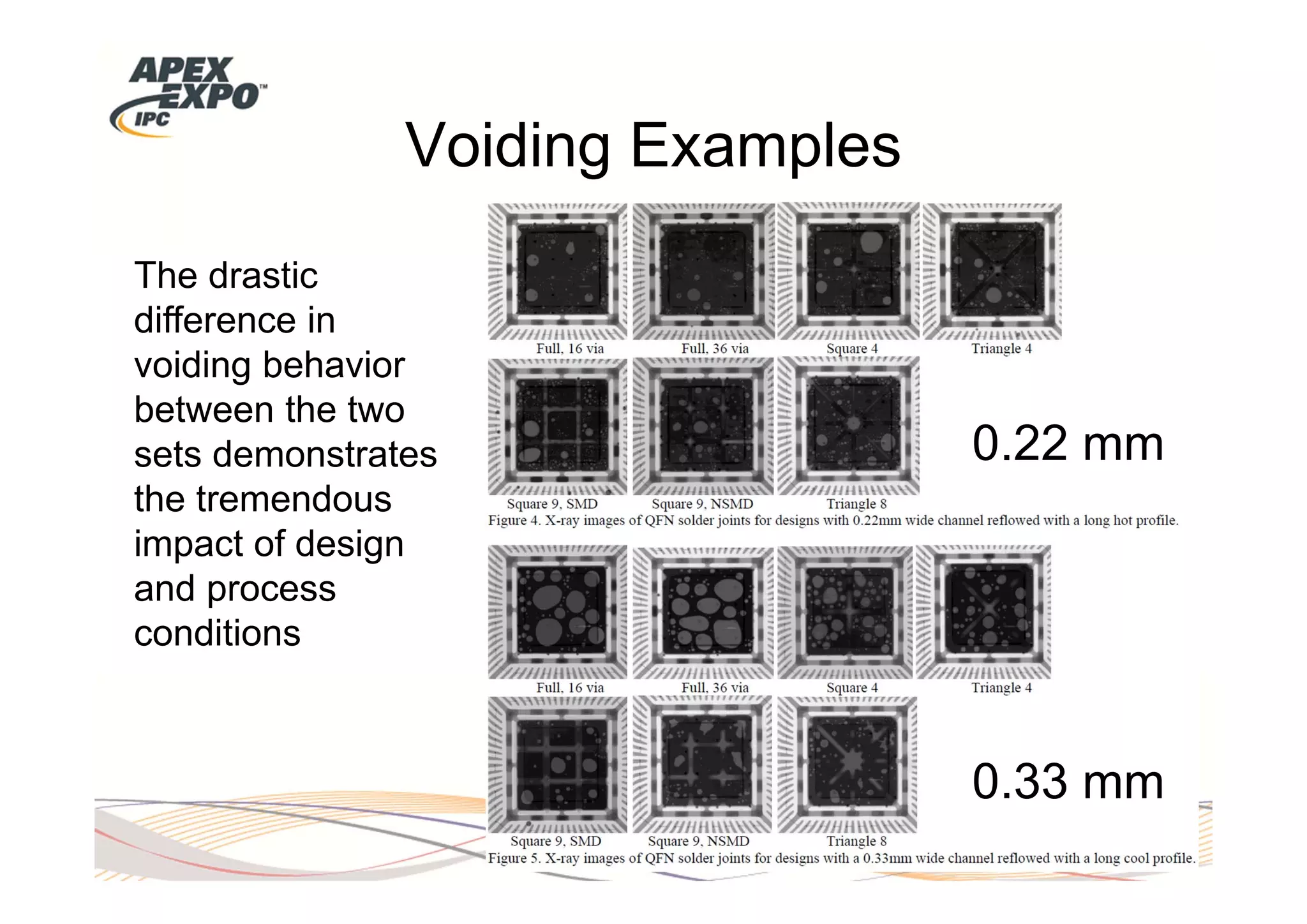

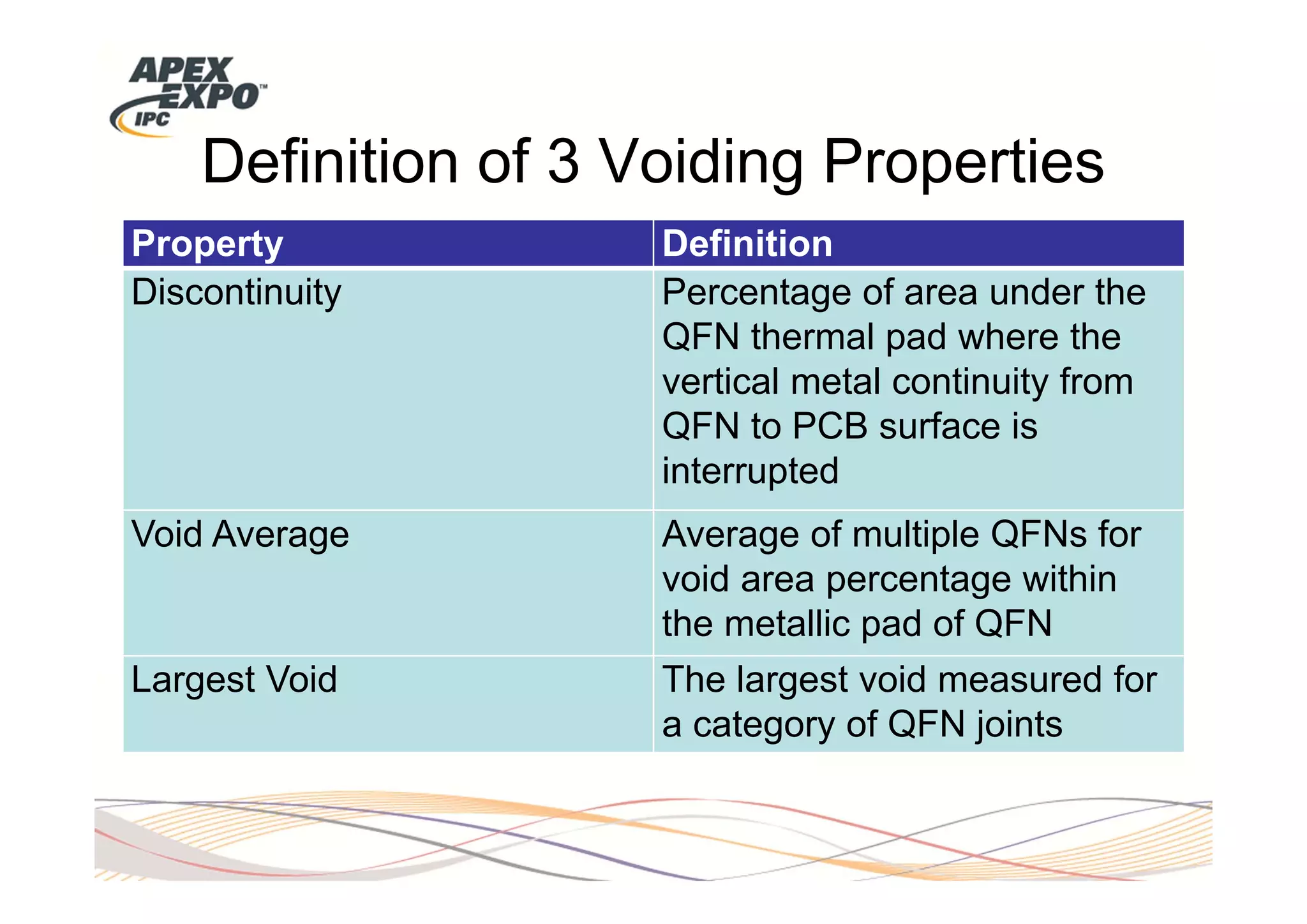

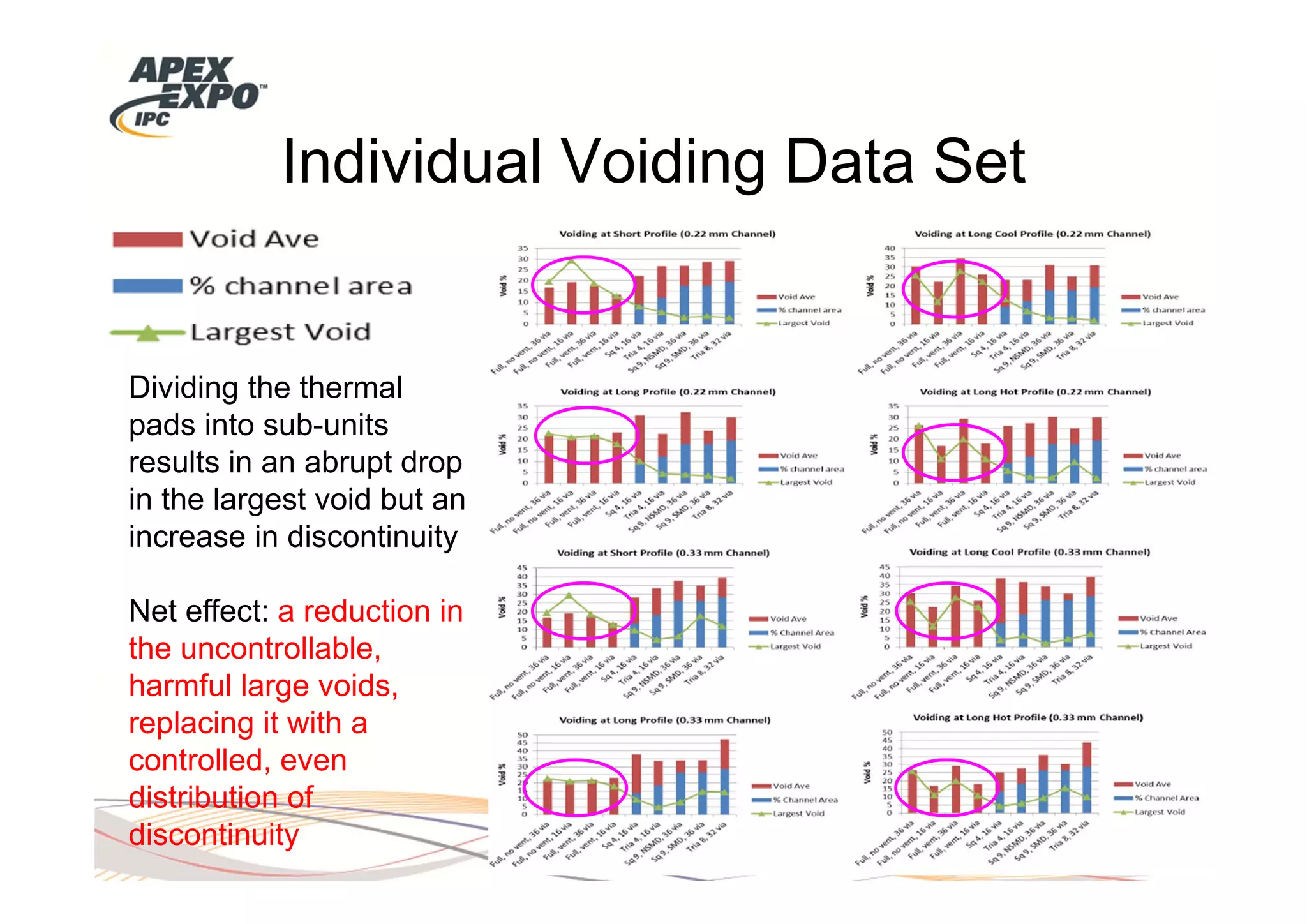

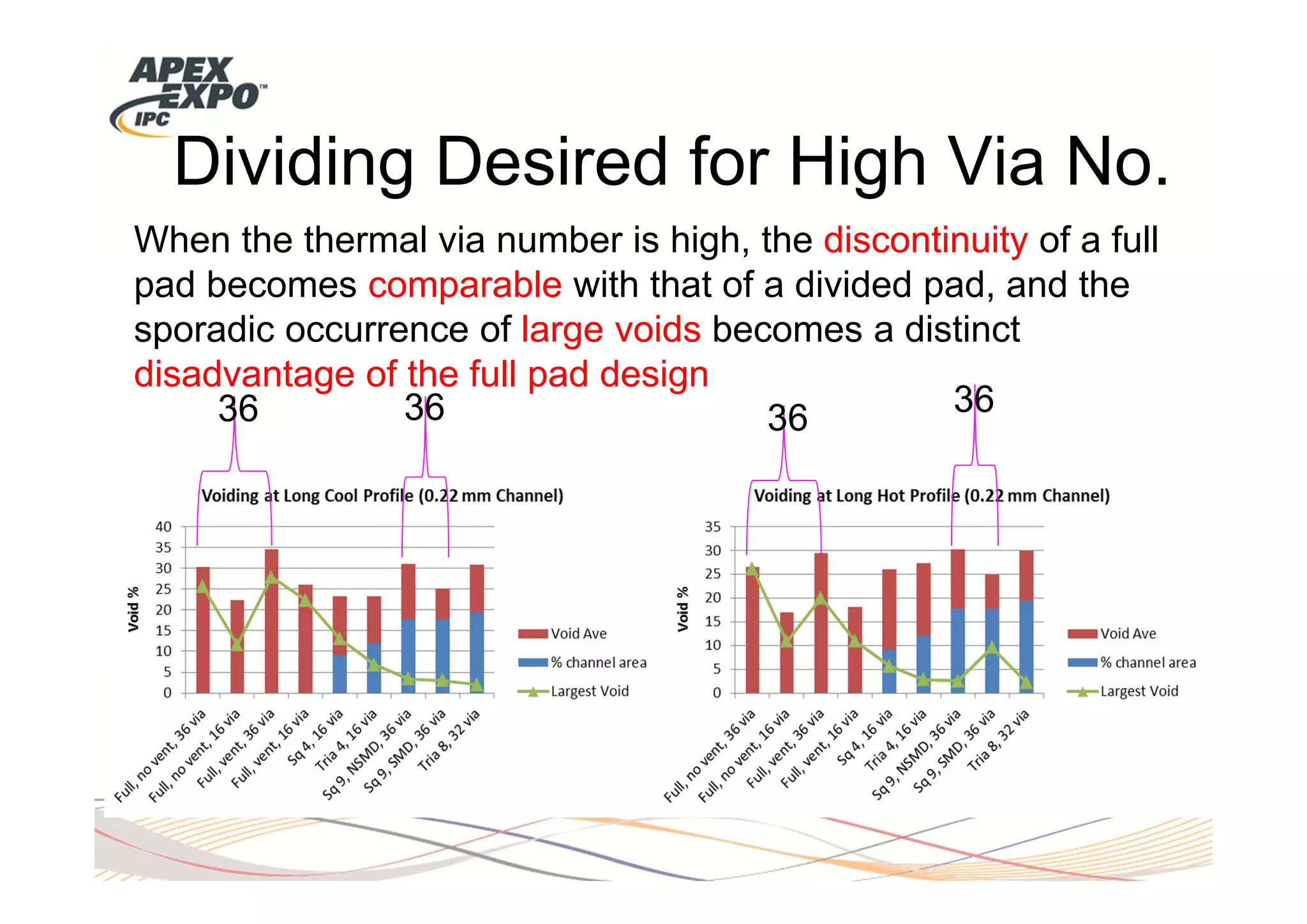

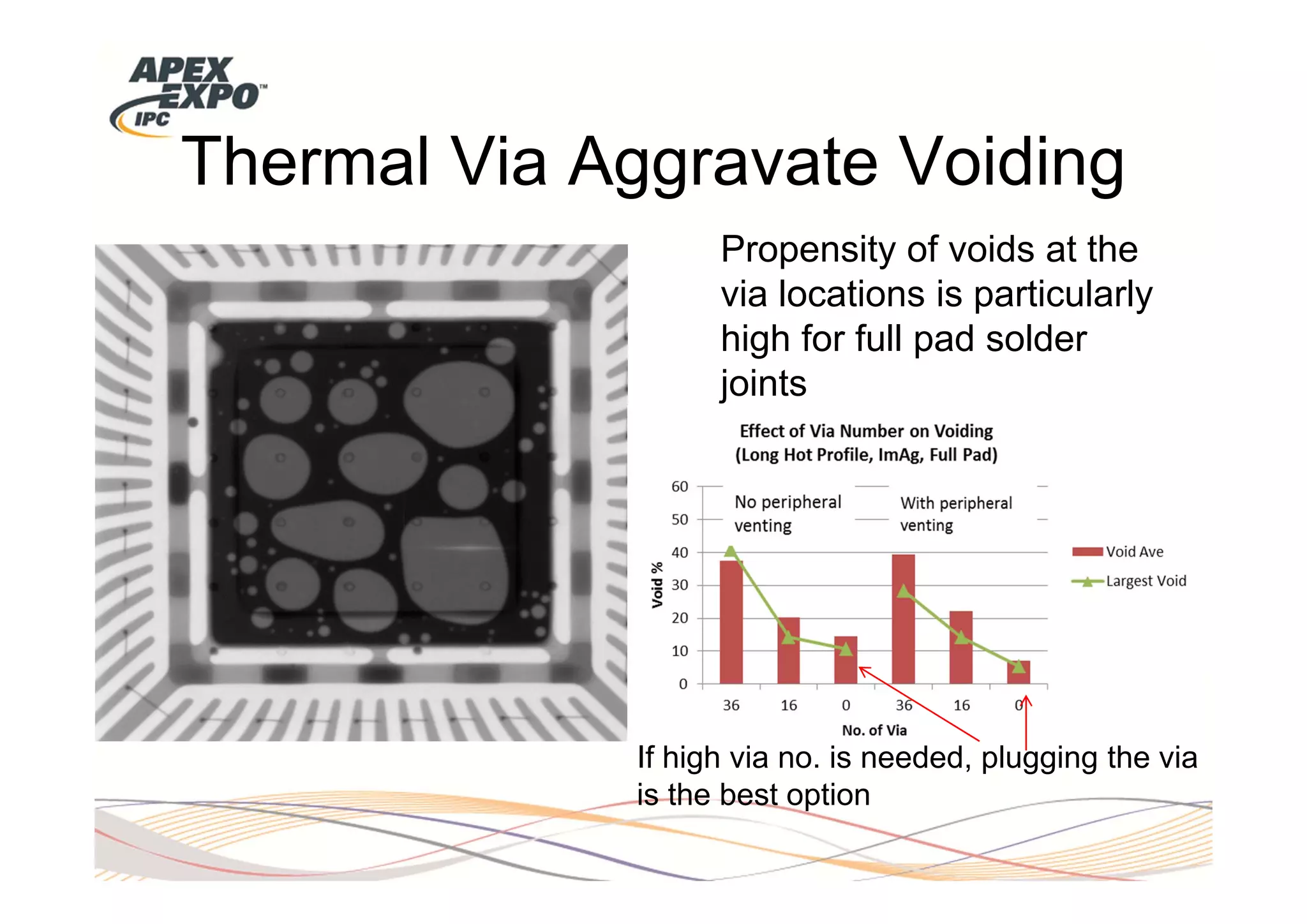

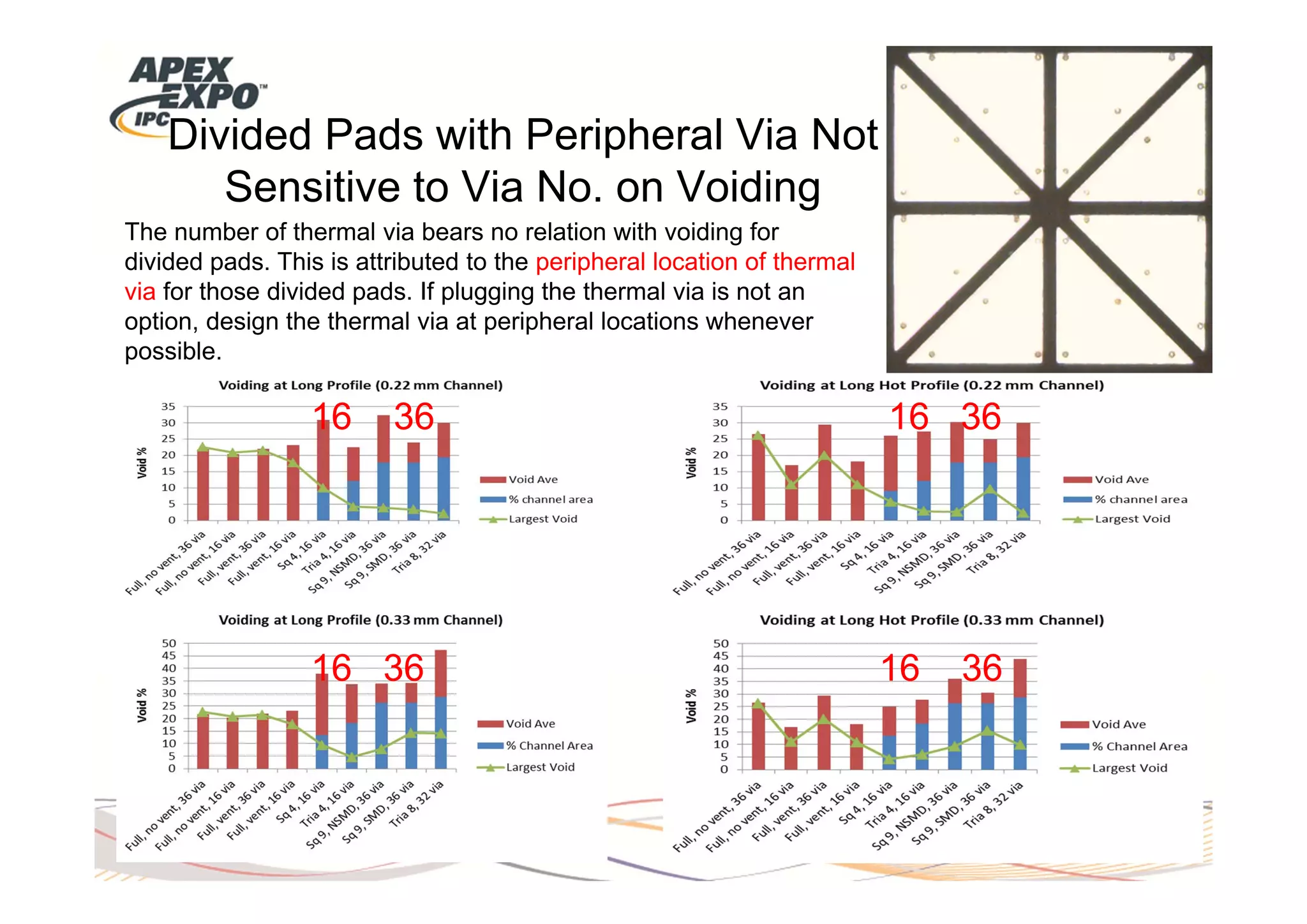

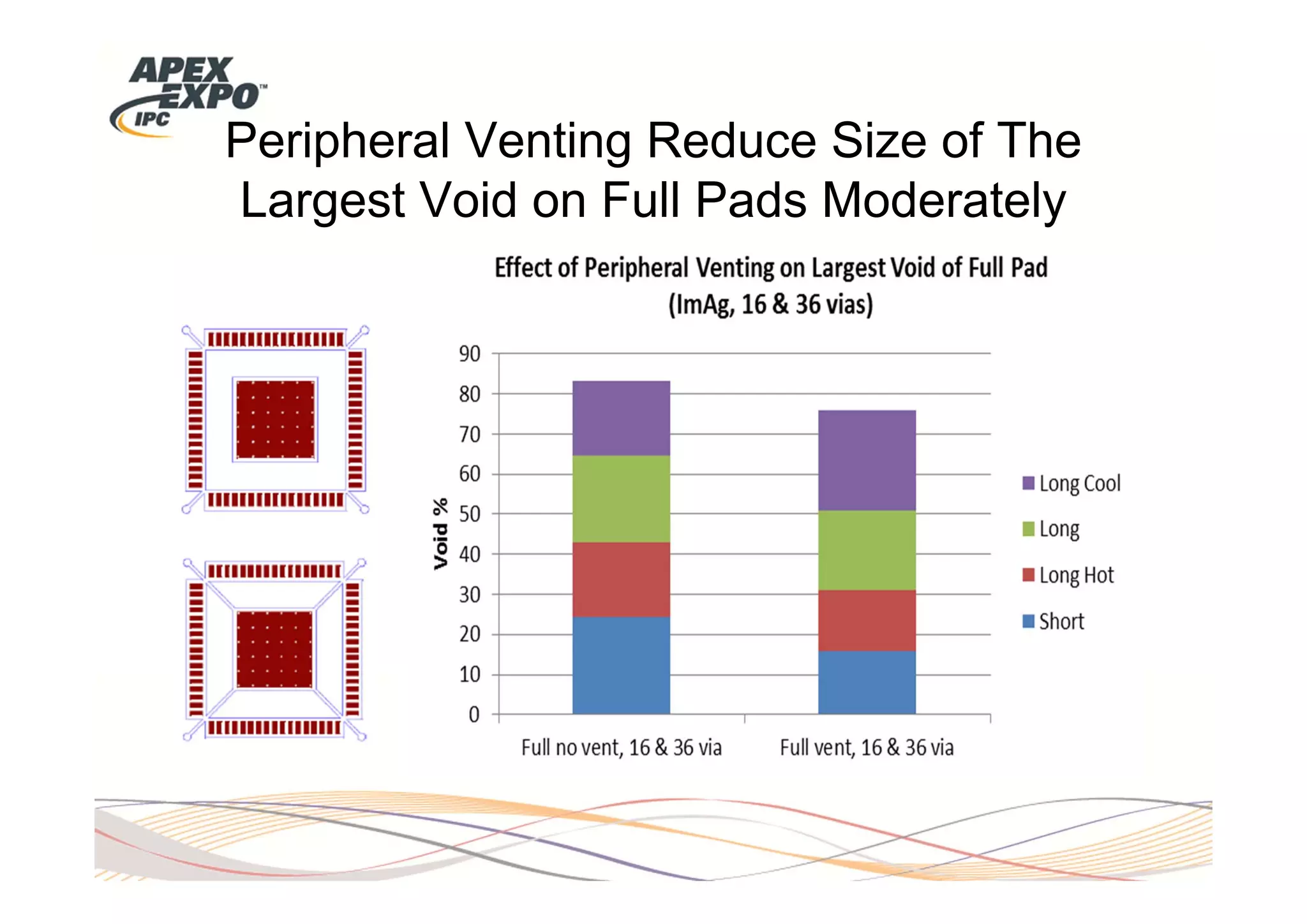

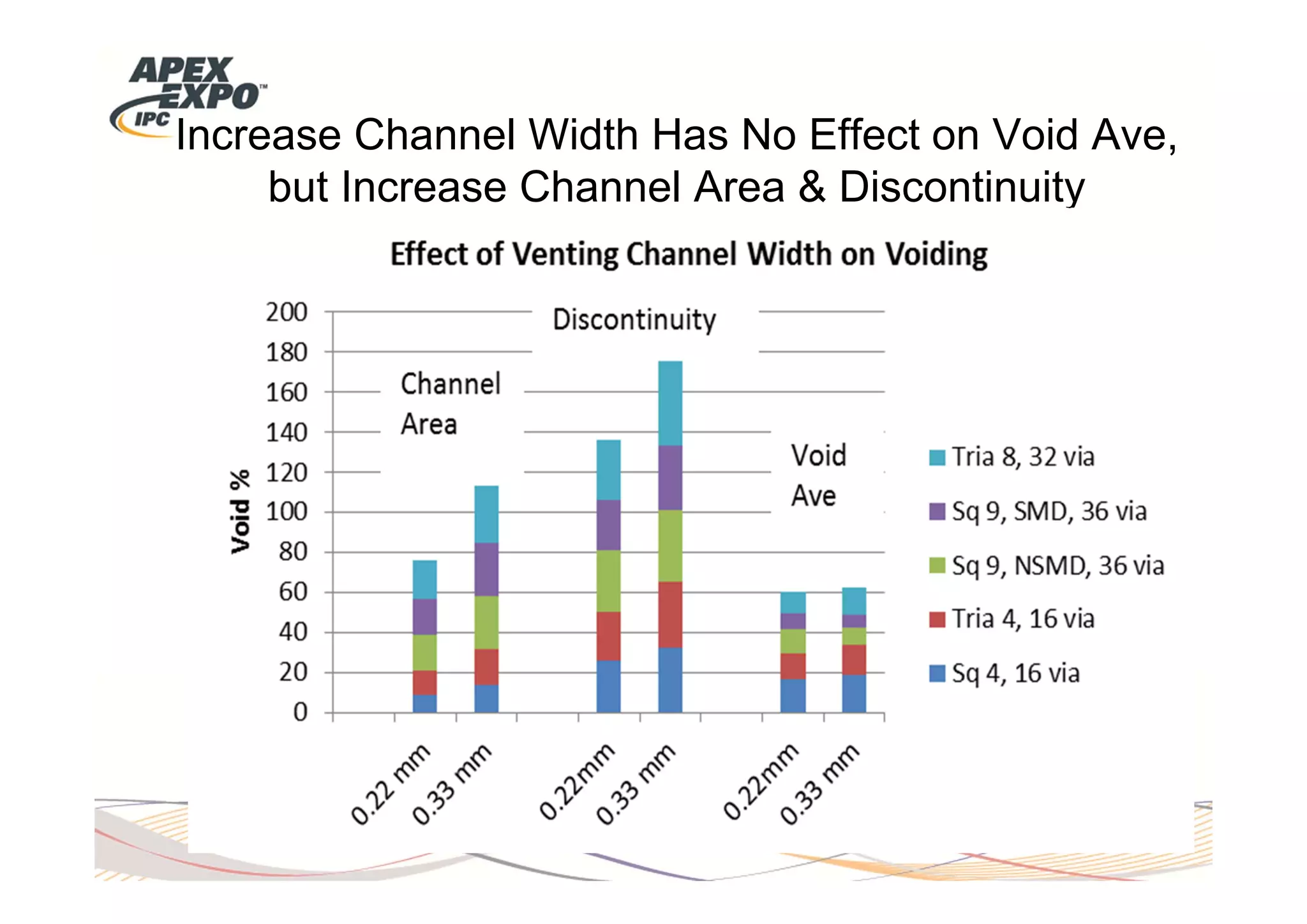

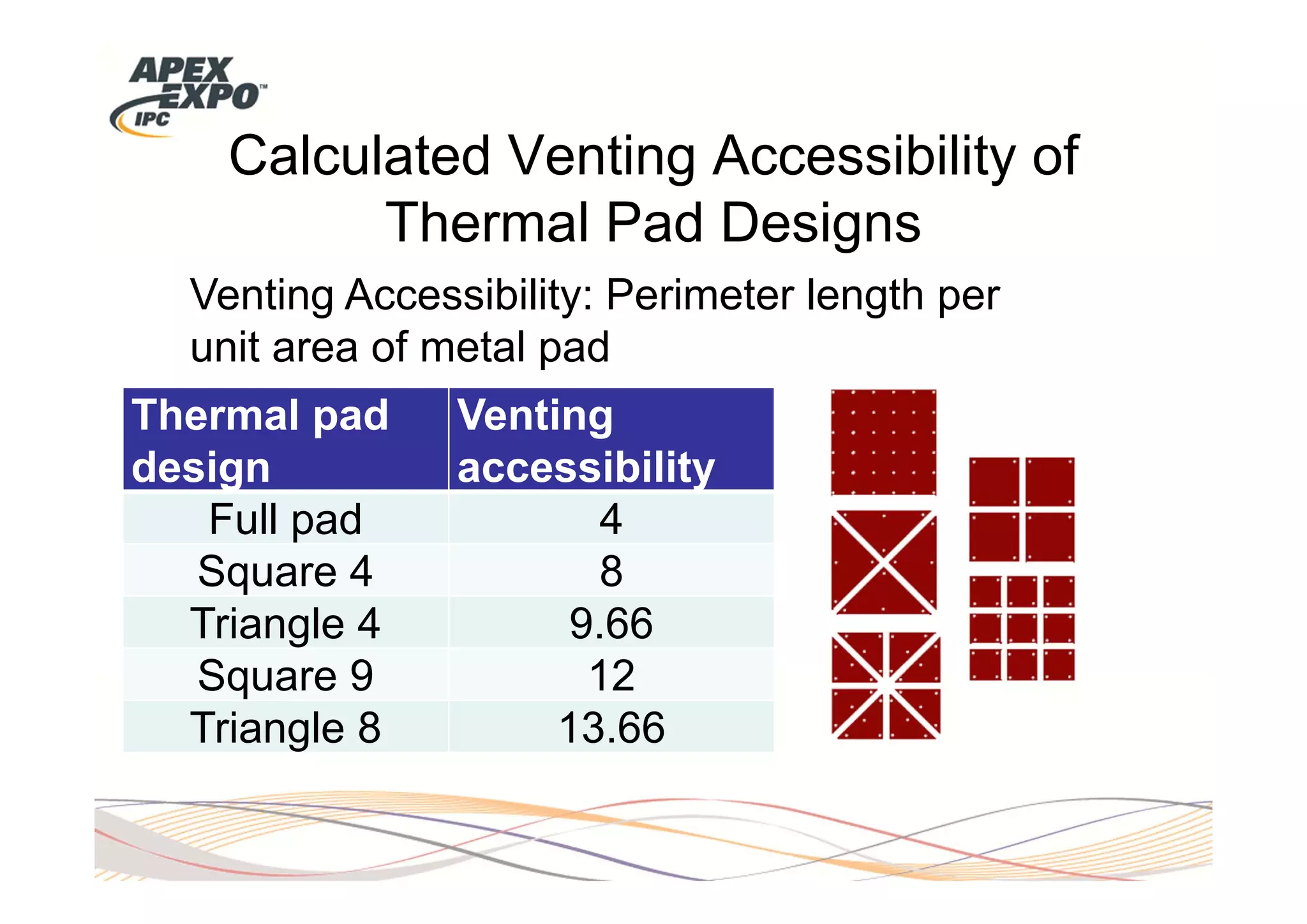

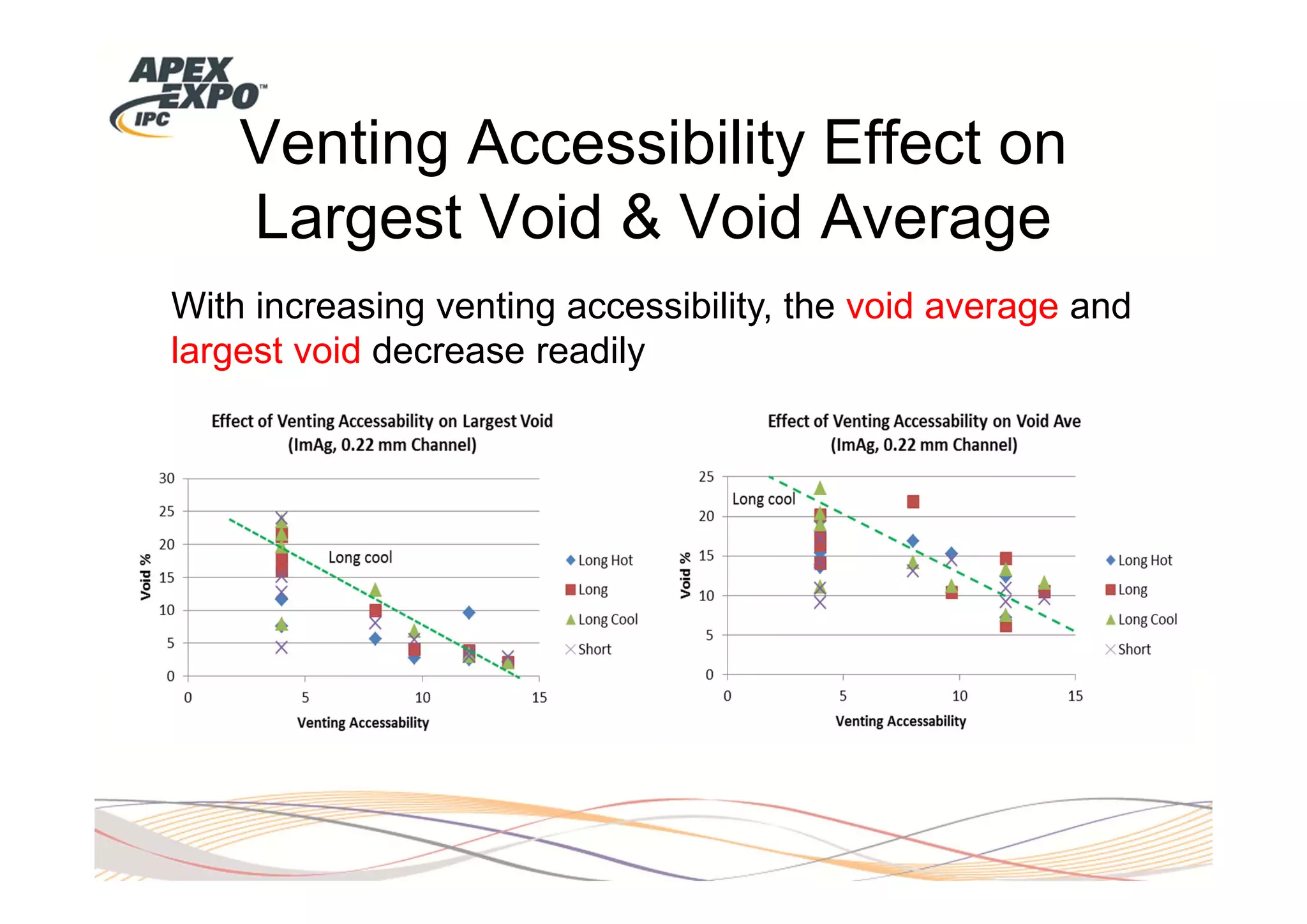

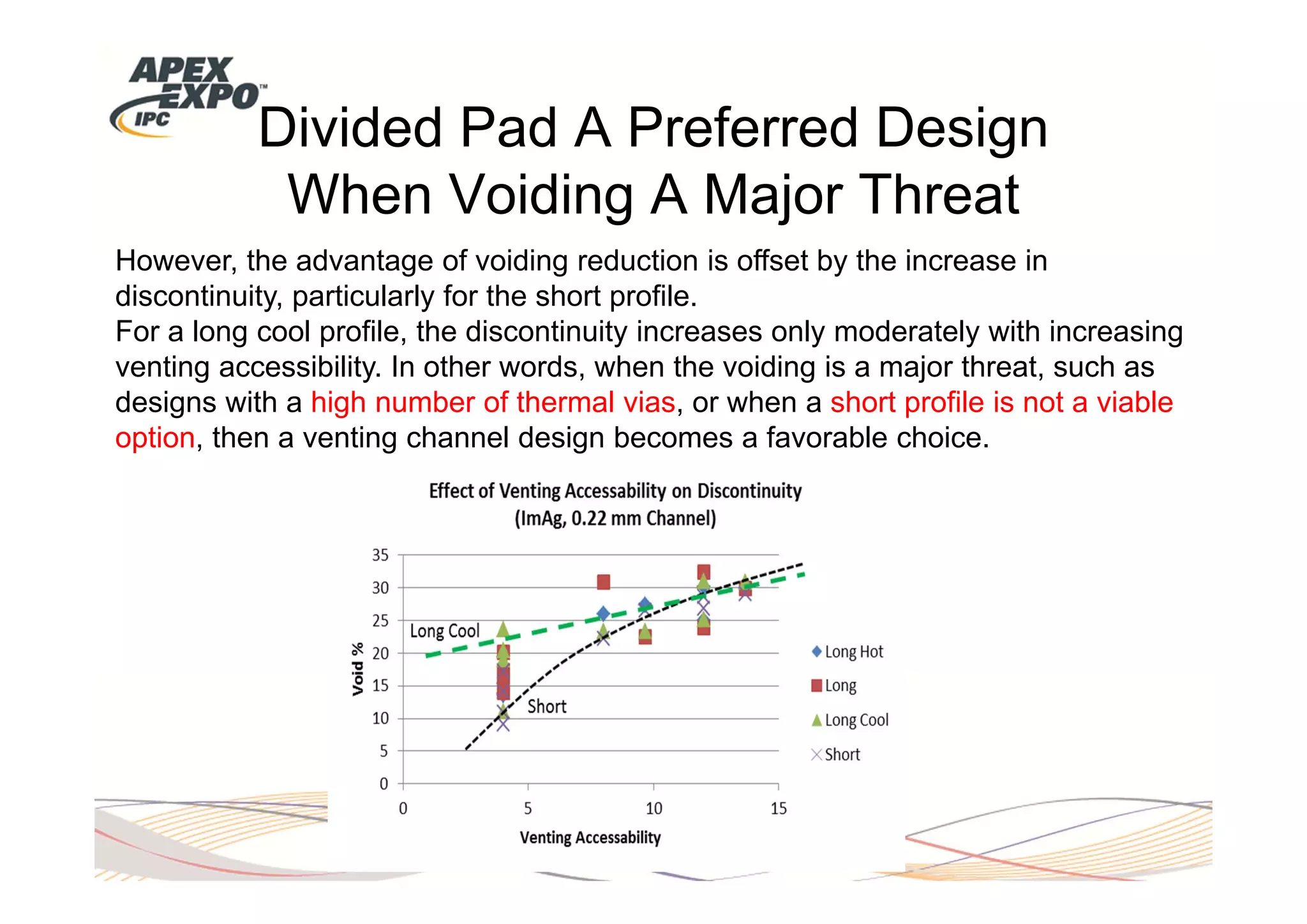

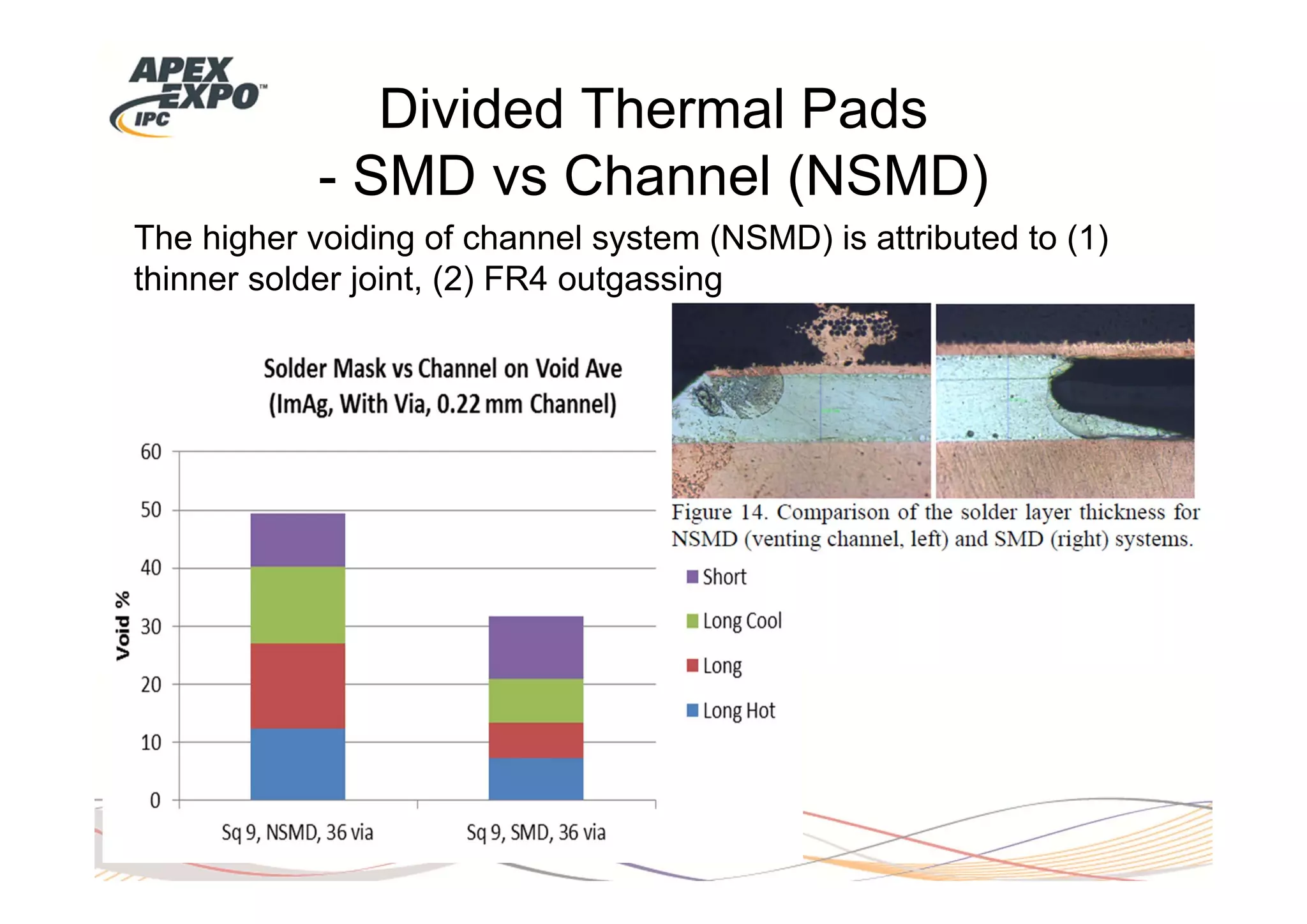

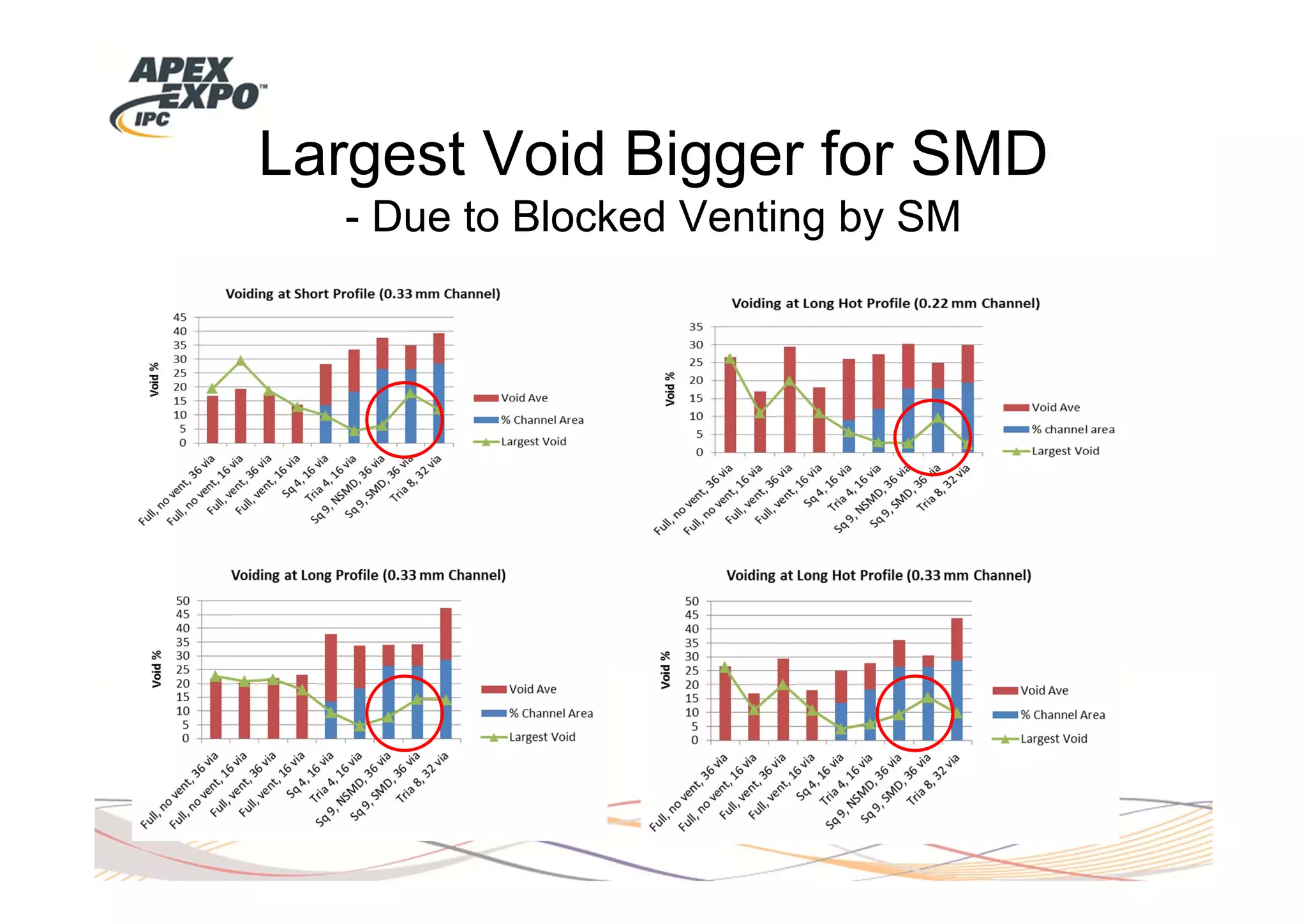

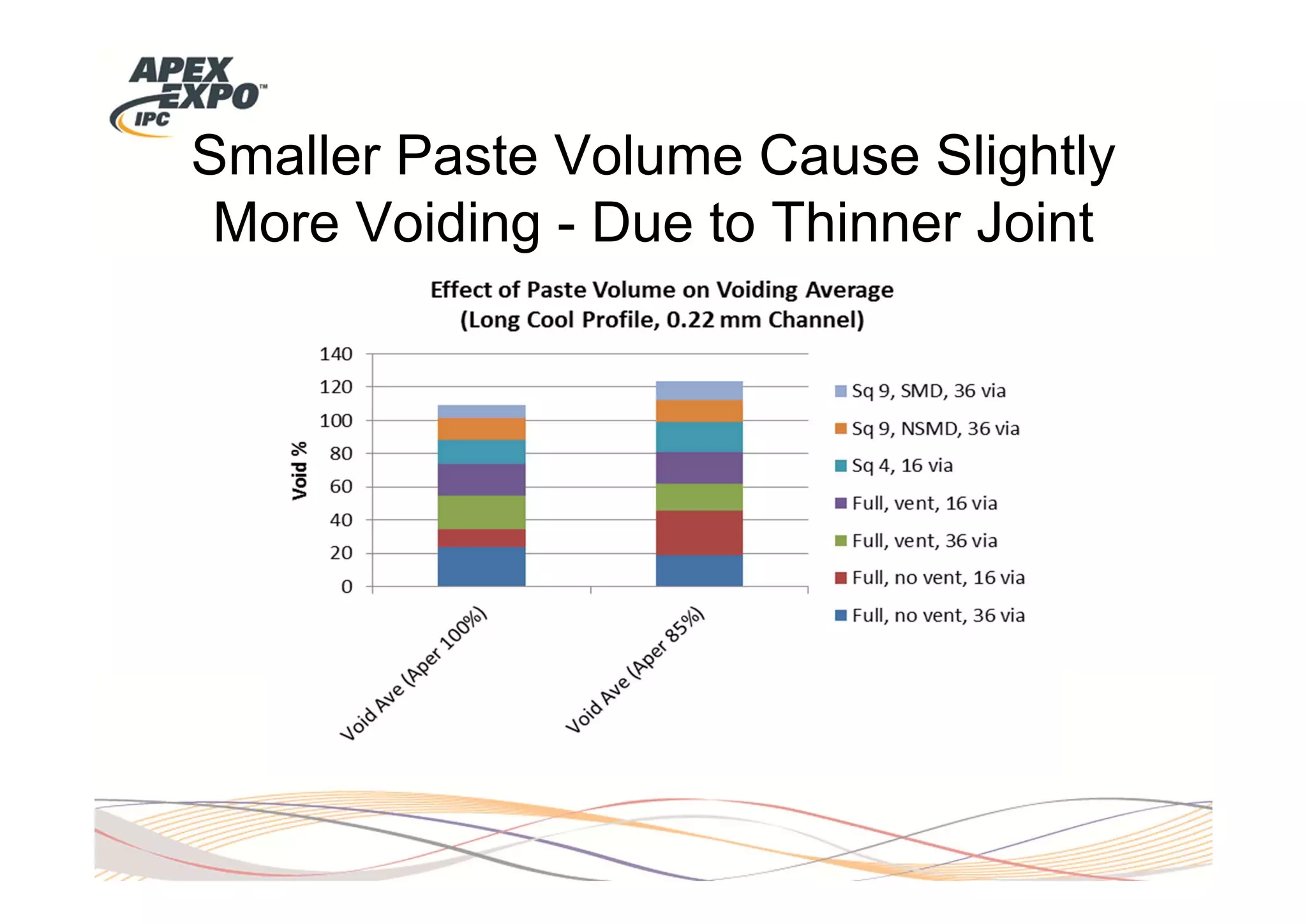

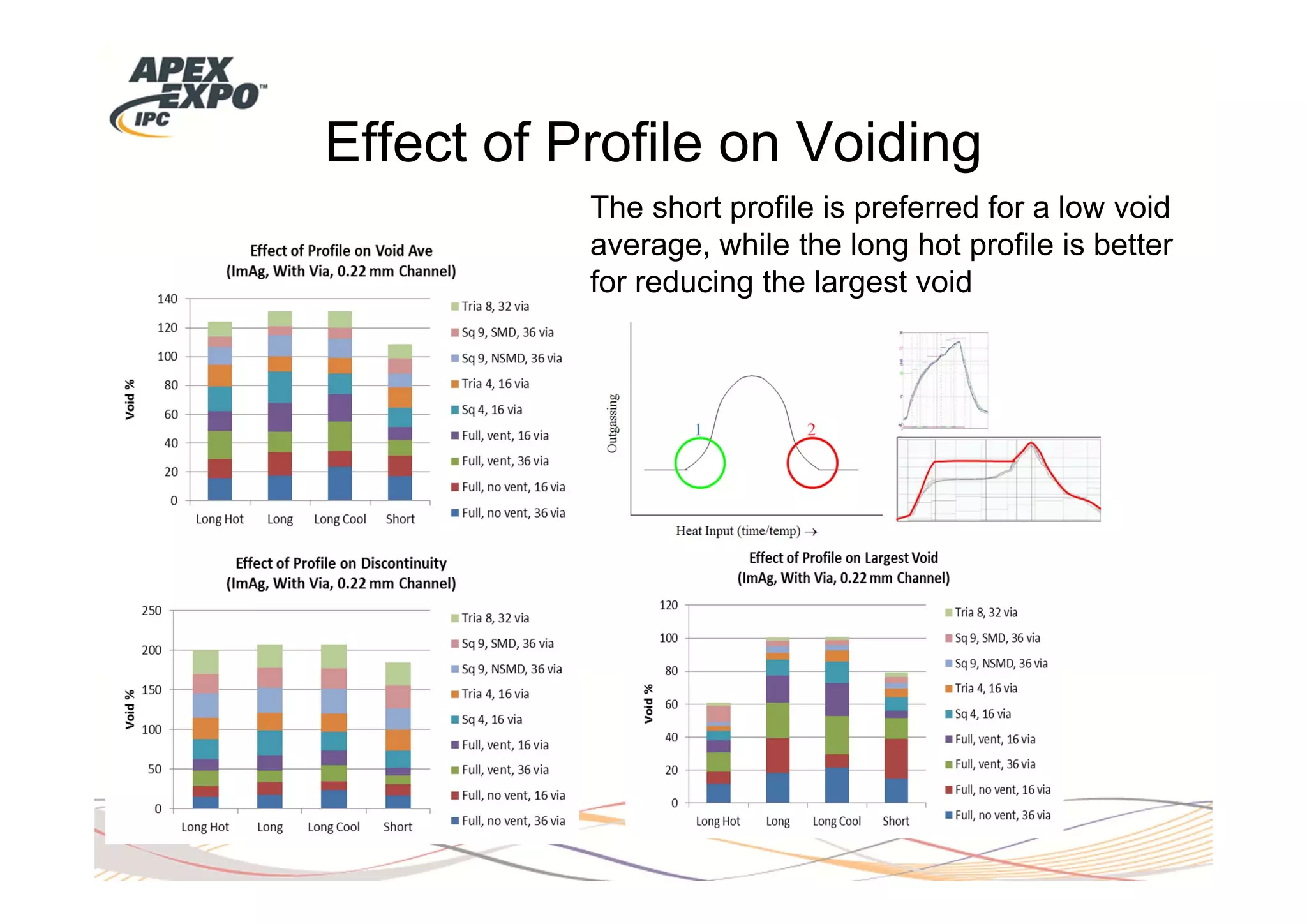

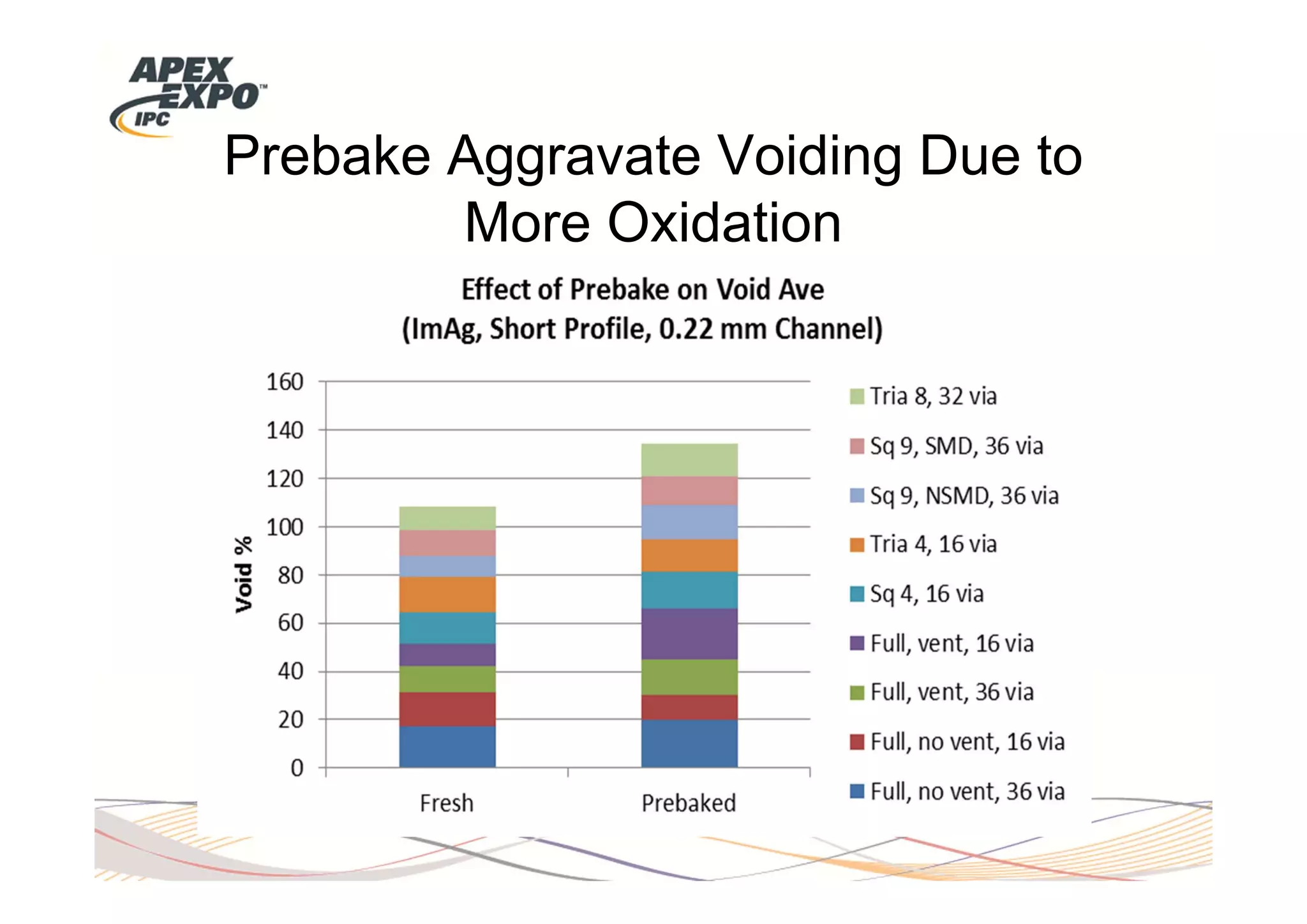

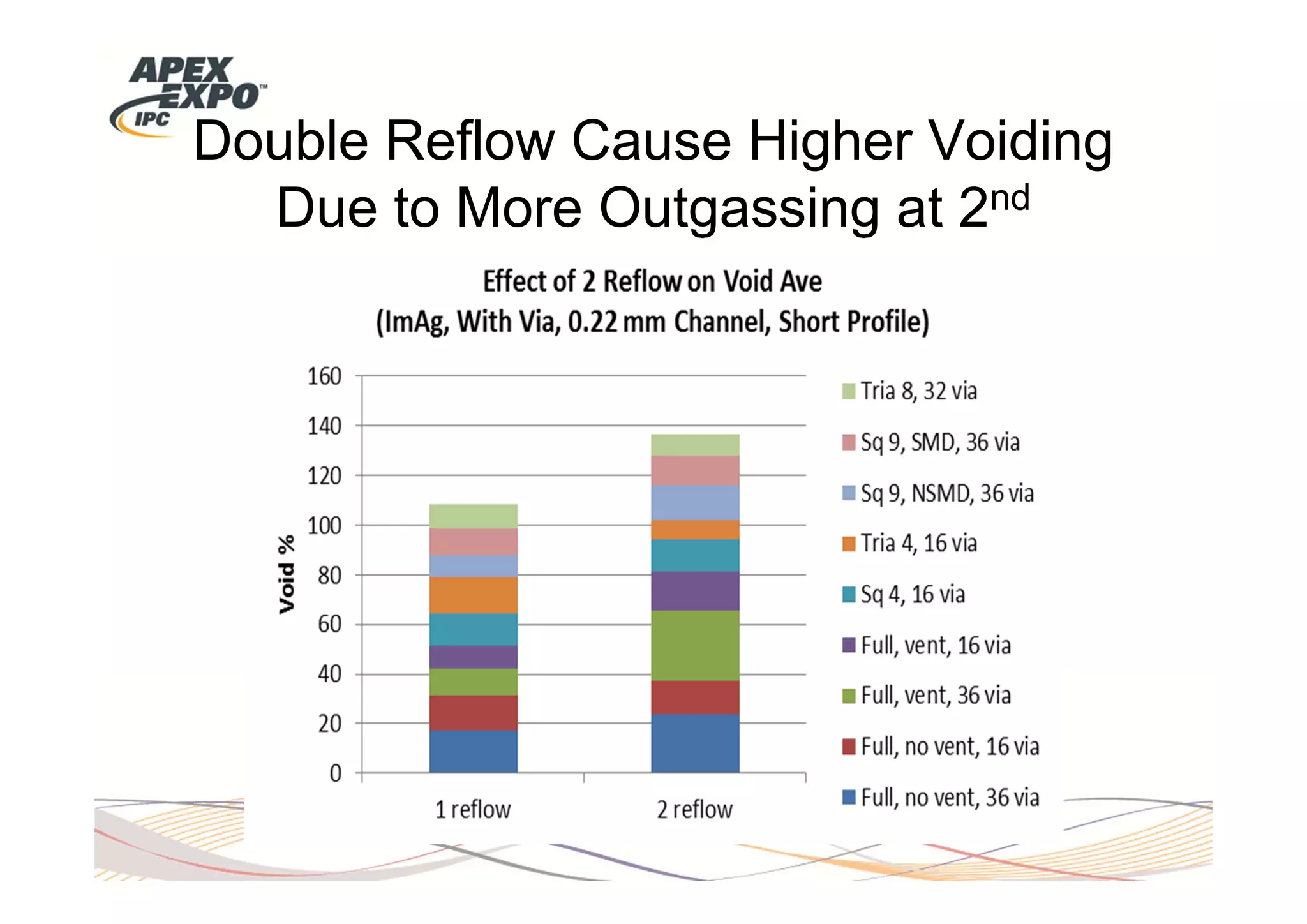

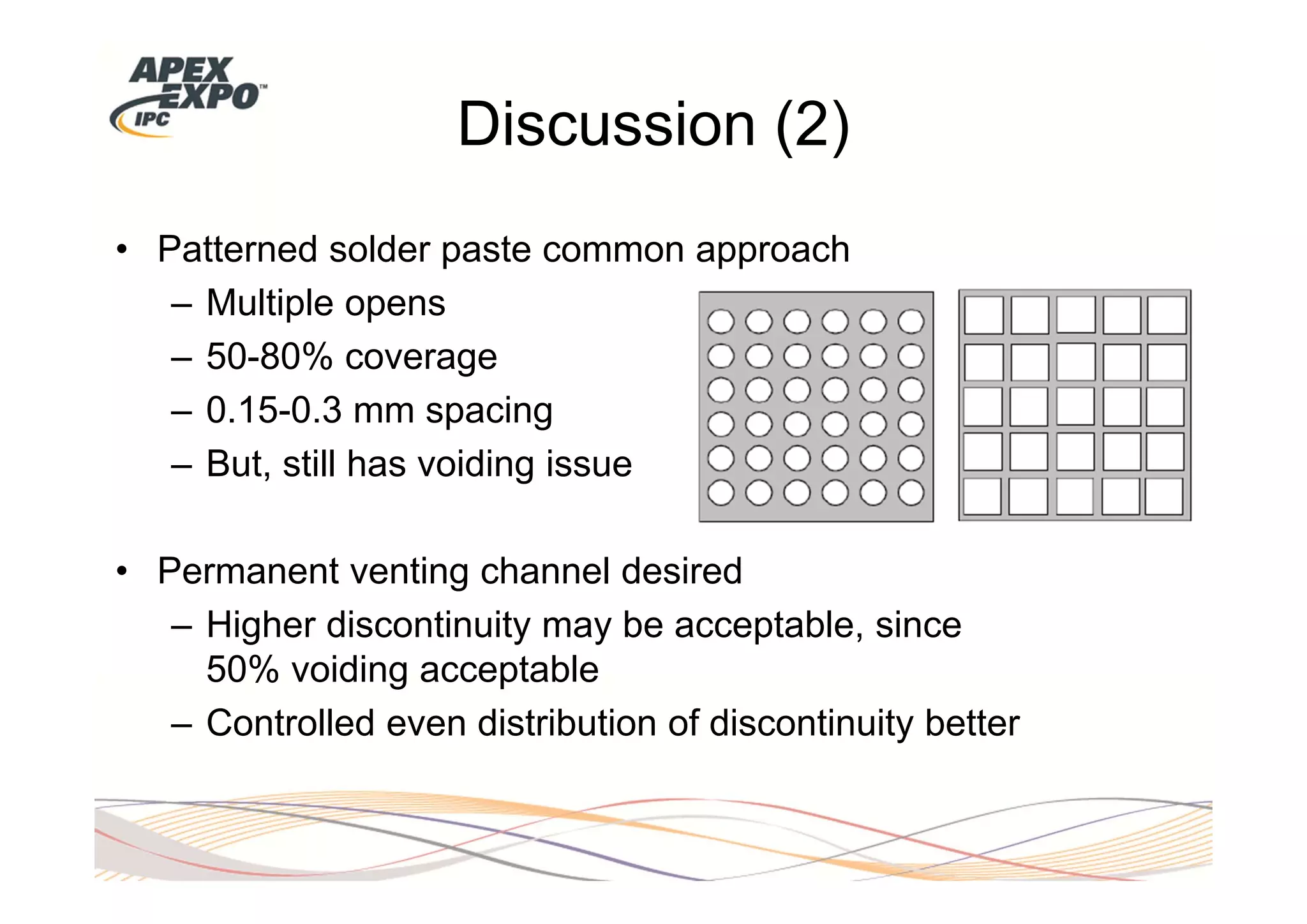

The document summarizes a study on pad design and process parameters to minimize voiding during QFN assembly. Key findings include: (1) Dividing large thermal pads into sub-units significantly reduces the largest voids while modestly increasing discontinuity; (2) Placing thermal vias peripherally or plugging vias is important when via number is high to control voiding; (3) Increased venting accessibility via sub-pad shape/number reduces voiding but compromises joint continuity.