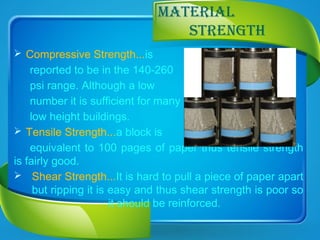

Papercrete is a building material made from recycled paper fiber, Portland cement, and soil. It has low density, good insulation properties, and moderate strength. While papercrete provides environmental and cost benefits, it lacks approval in building codes of most cities, limiting its use in load-bearing structures. More research is still needed to establish standardized production methods and assess long-term durability.