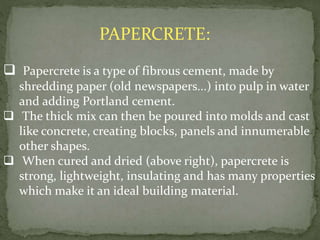

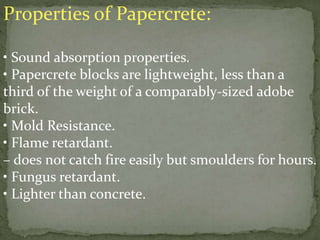

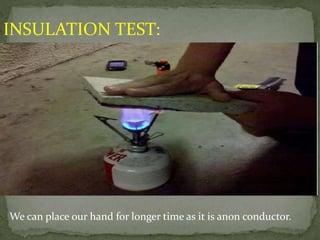

Papercrete is a building material made from a mixture of shredded paper, water, and Portland cement. It can be poured into molds and sets into strong, lightweight blocks like concrete. Papercrete has insulating and sound absorbing properties that make it suitable for construction. While it is not structurally strong enough for load-bearing walls, papercrete can be used for inner walls and decoration. It is an environmentally friendly alternative to concrete that utilizes waste paper but lacks regulatory approval and its use at large scale could increase deforestation.

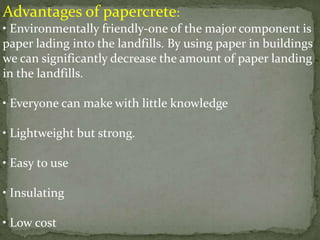

![Preparation:

Use volatile sources

– Water + waste paper + portland cement[binder]

Add water upto 2/3rd height Tow mixture contents

sharp blade to chop paper and to mix.

Collect waste papers.

Put in tank paper + portland cement

After running the tow mixture for four to five minutes

at moderate speed.

Level it equally

Wait for 20-30 minutes so that excess water can drain

out after 3-4 four sunny day](https://image.slidesharecdn.com/papercrete-150228112832-conversion-gate01/85/Papercrete-3-320.jpg)

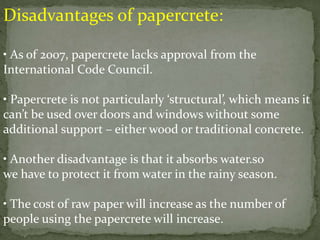

![Future:

• Trying to reduce the amount of concrete required

to prepare the papercrete with same strength

and also ultimately reduce CO2 amount.

• Decrease in the carbon footprint of the house.

• Use of different materials at the place of cement

such as gypsum and lime.

• sustainable construction materials, decorating

materials and etc.

• Large market in Africa , India , China [because

people has less money]](https://image.slidesharecdn.com/papercrete-150228112832-conversion-gate01/85/Papercrete-12-320.jpg)