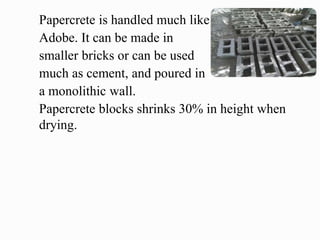

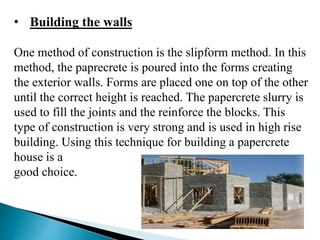

Papercrete is a building material made from recycled paper, Portland cement, and sand. It is produced by mixing these ingredients into a slurry that can be poured and molded like concrete. Papercrete has benefits like being lightweight, a good insulator, and environmentally friendly since it uses recycled paper. However, it also has drawbacks like low structural strength, absorbency of water, and lack of approval by building codes. Overall, papercrete is a sustainable building material option for small, single-story structures.