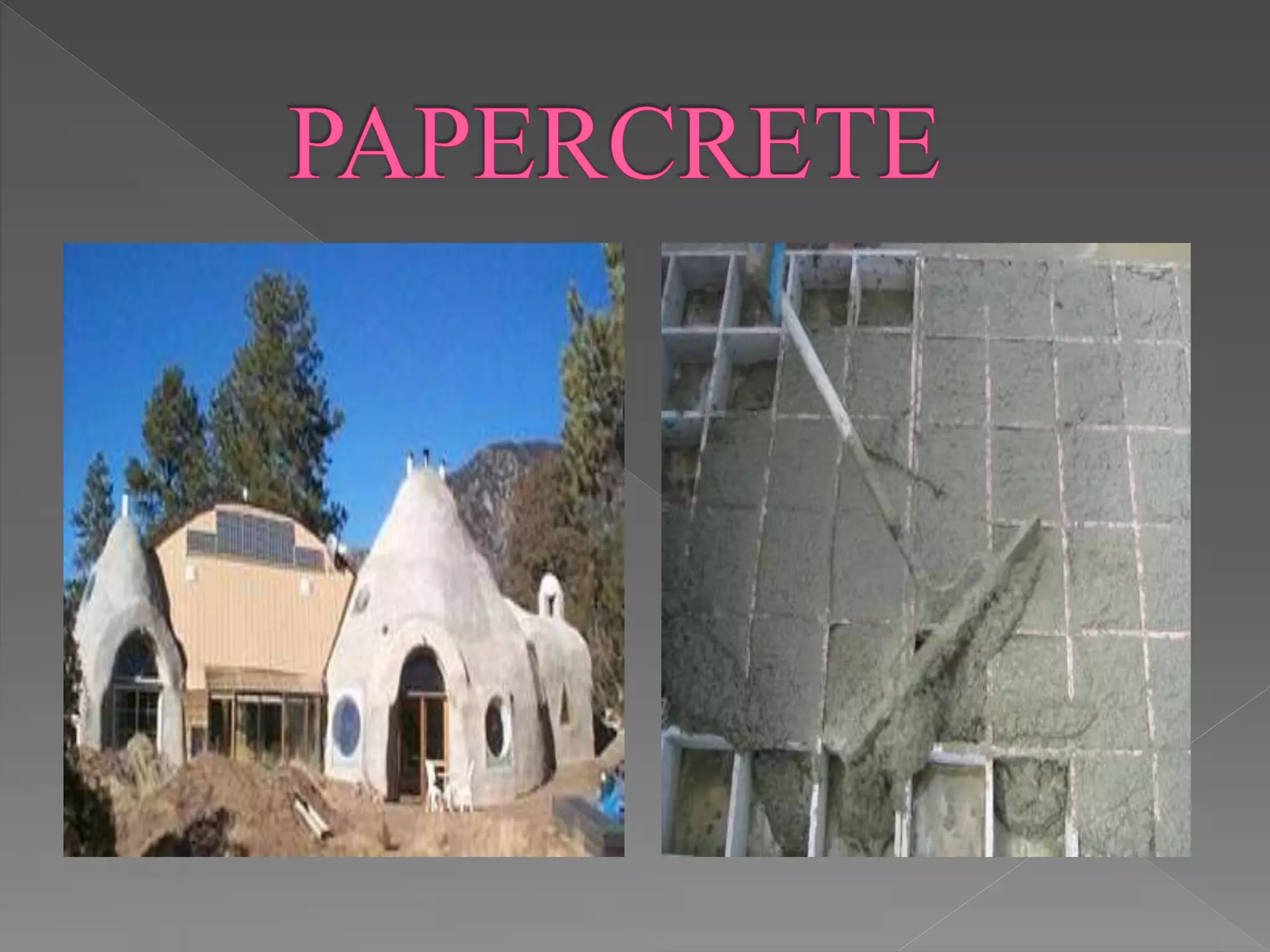

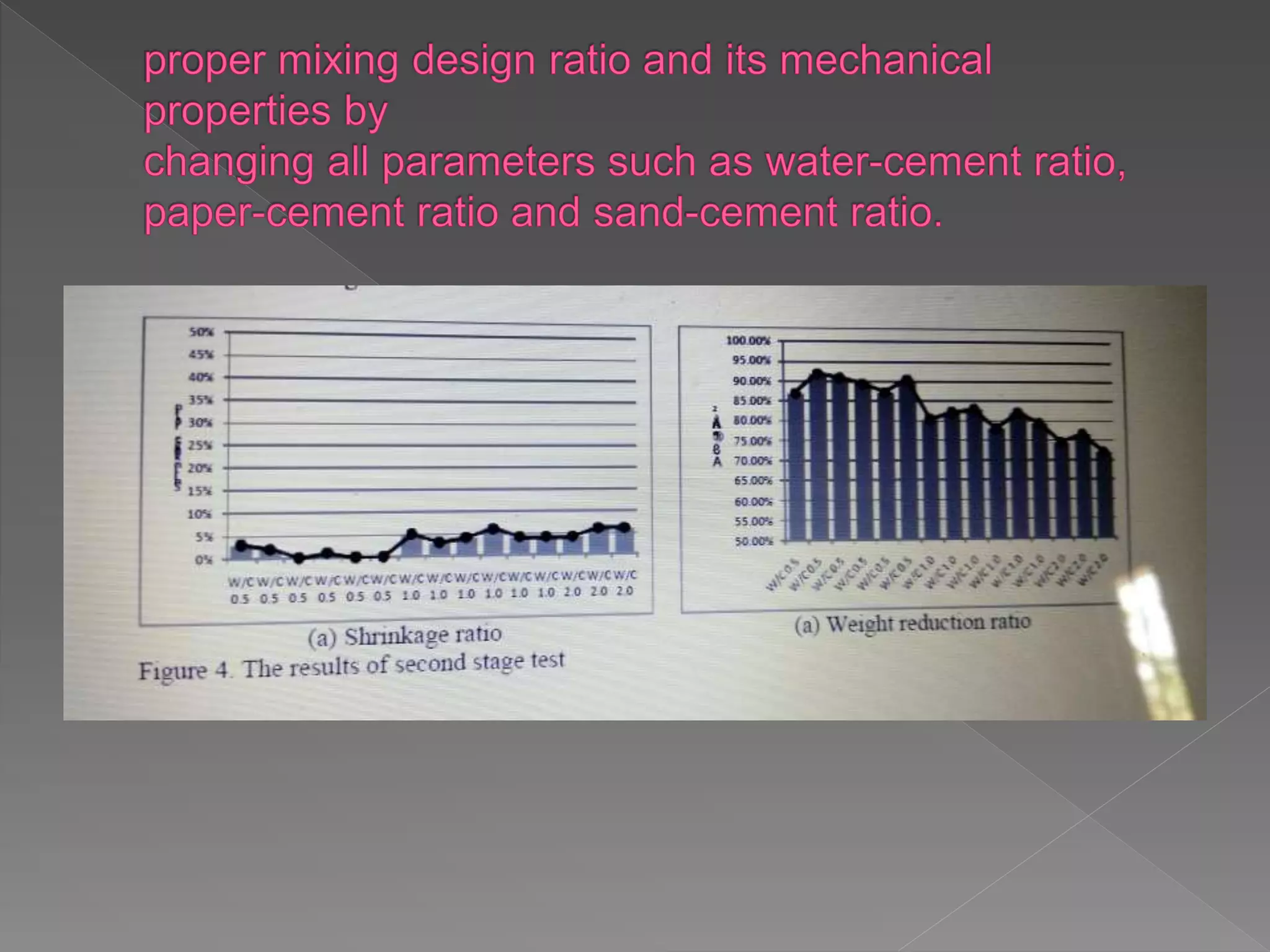

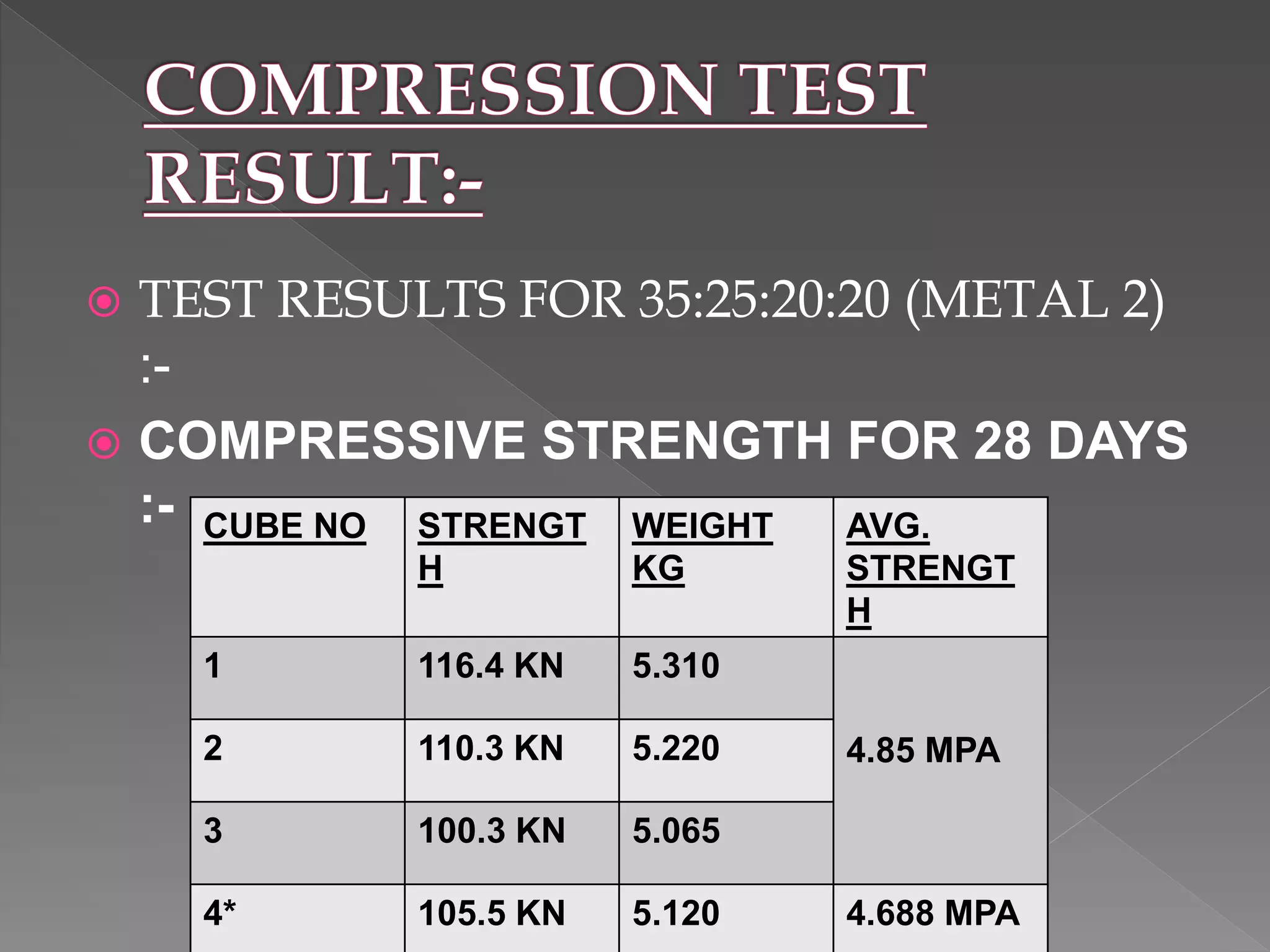

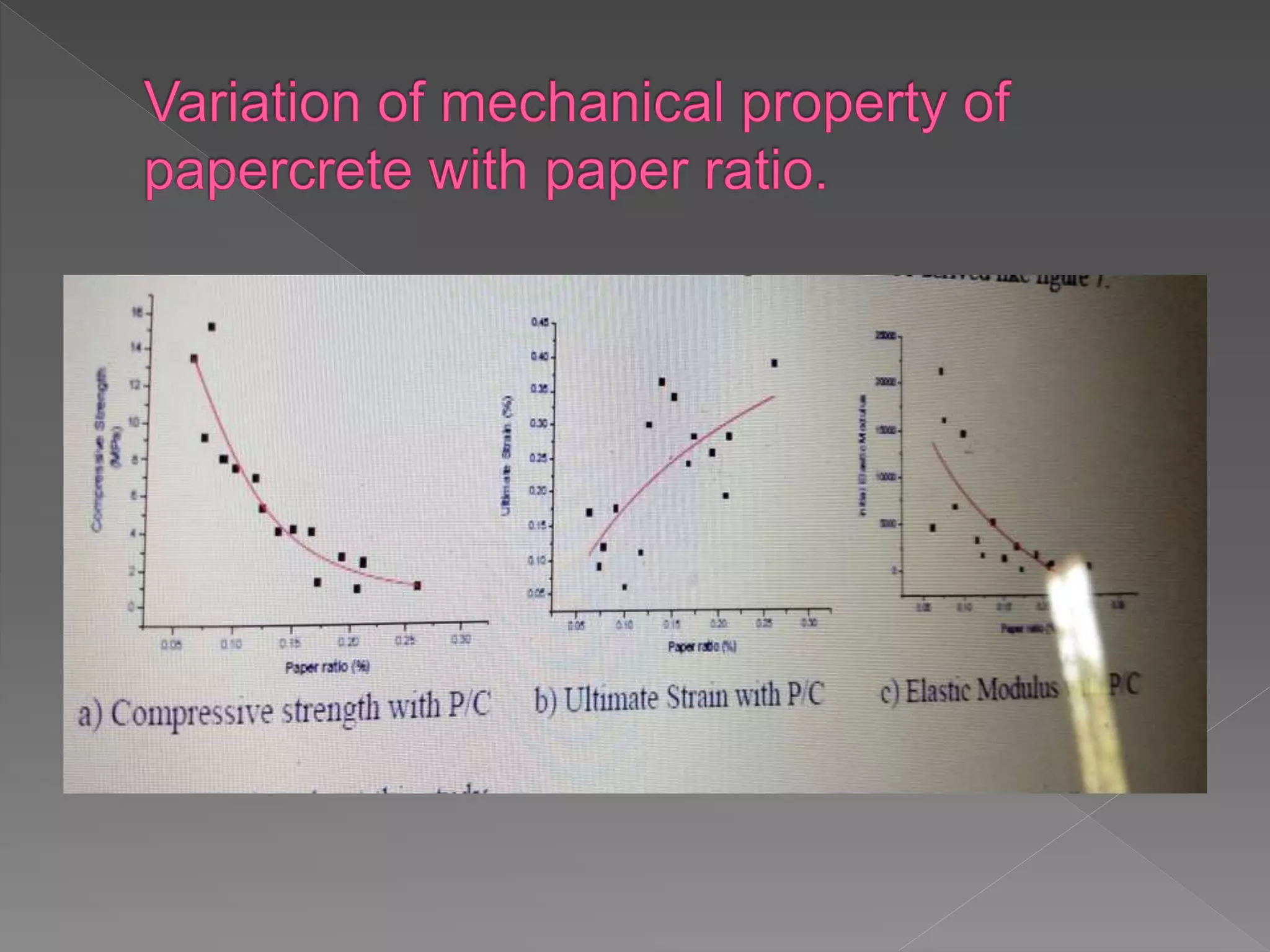

This document discusses paper-crete, a building material made from recycled paper, cement, and sand. It provides details on the material's composition and properties. The objective of the project was to design and test paper-crete wall panels. Several mixes were tested by casting cubes with different ratios of materials. The cubes were cured and tested to determine compressive strength after 7 and 28 days. Results showed compressive strengths ranging from 1.35 to 4.85 MPa depending on the mix, with oven drying increasing strength compared to air drying. The conclusion is that paper-crete is a lighter alternative to bricks for inner wall construction.