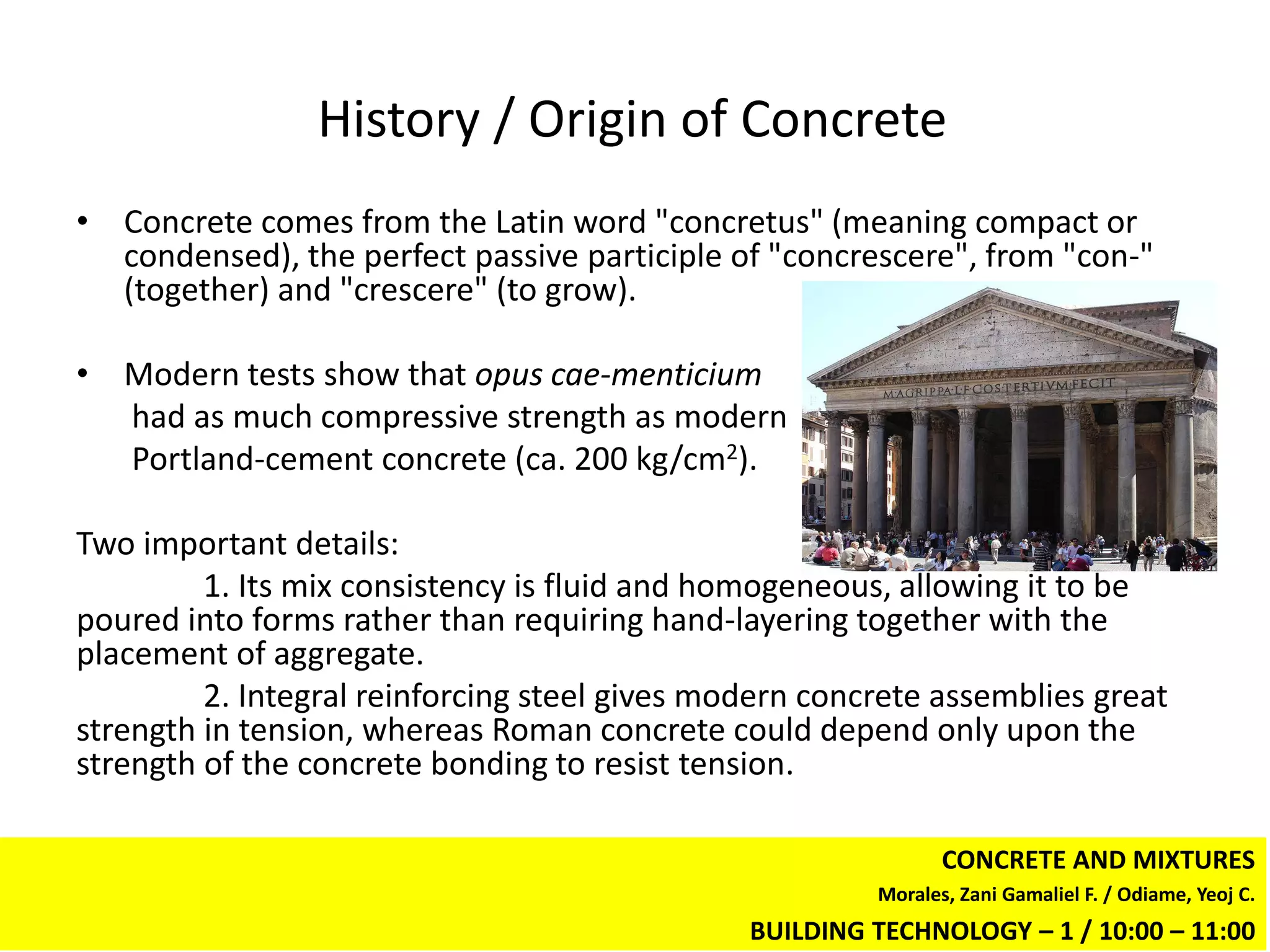

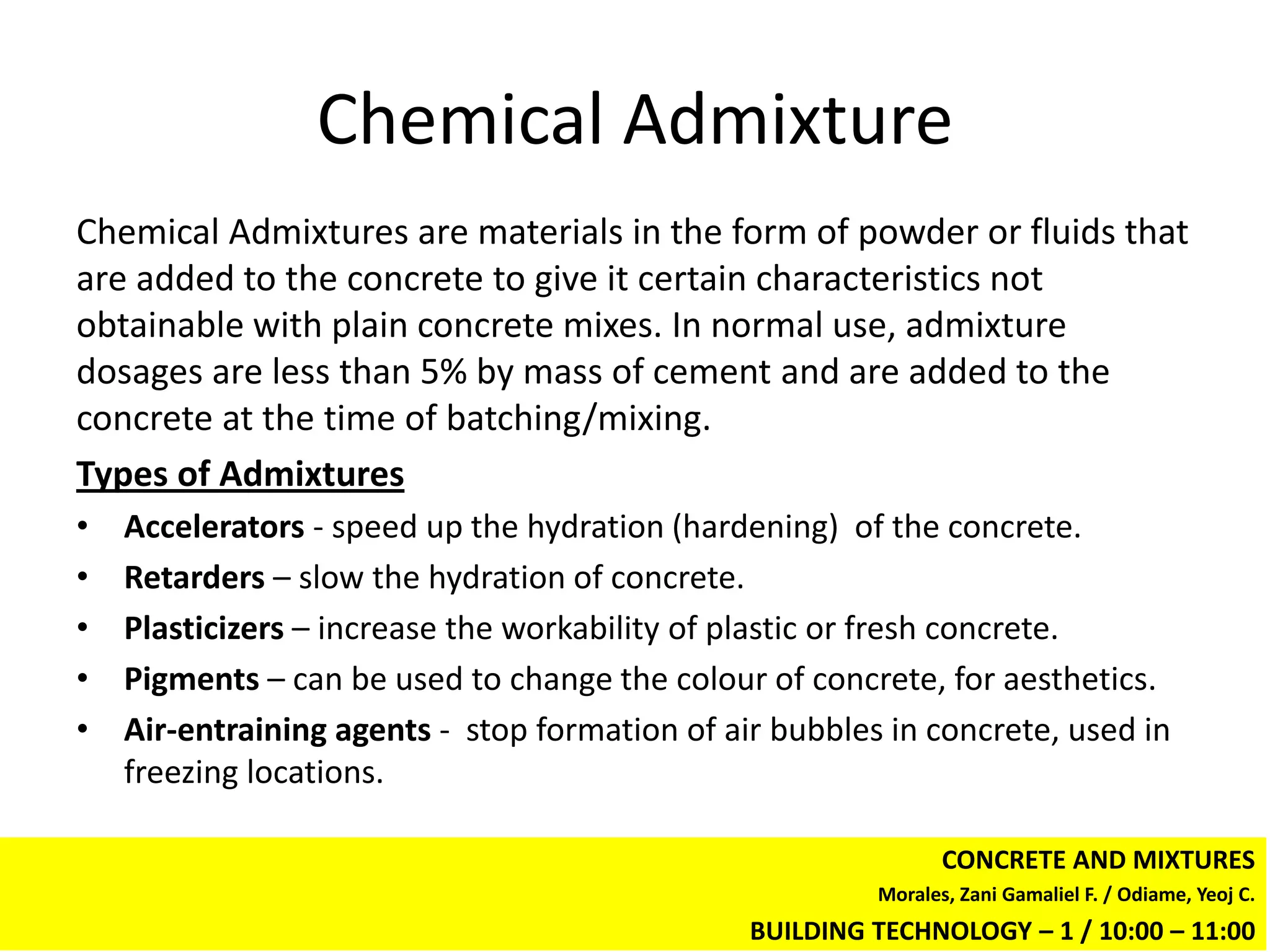

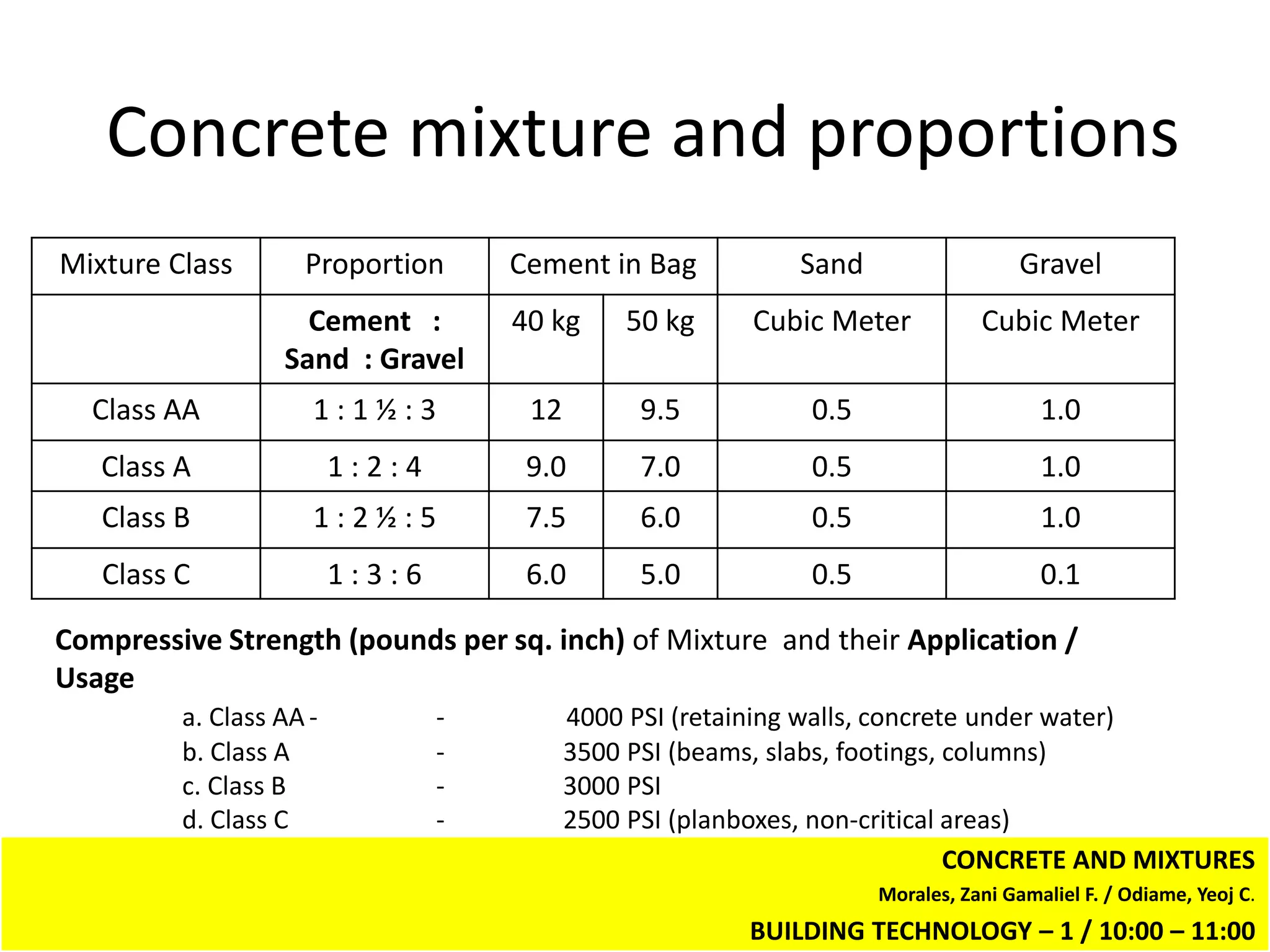

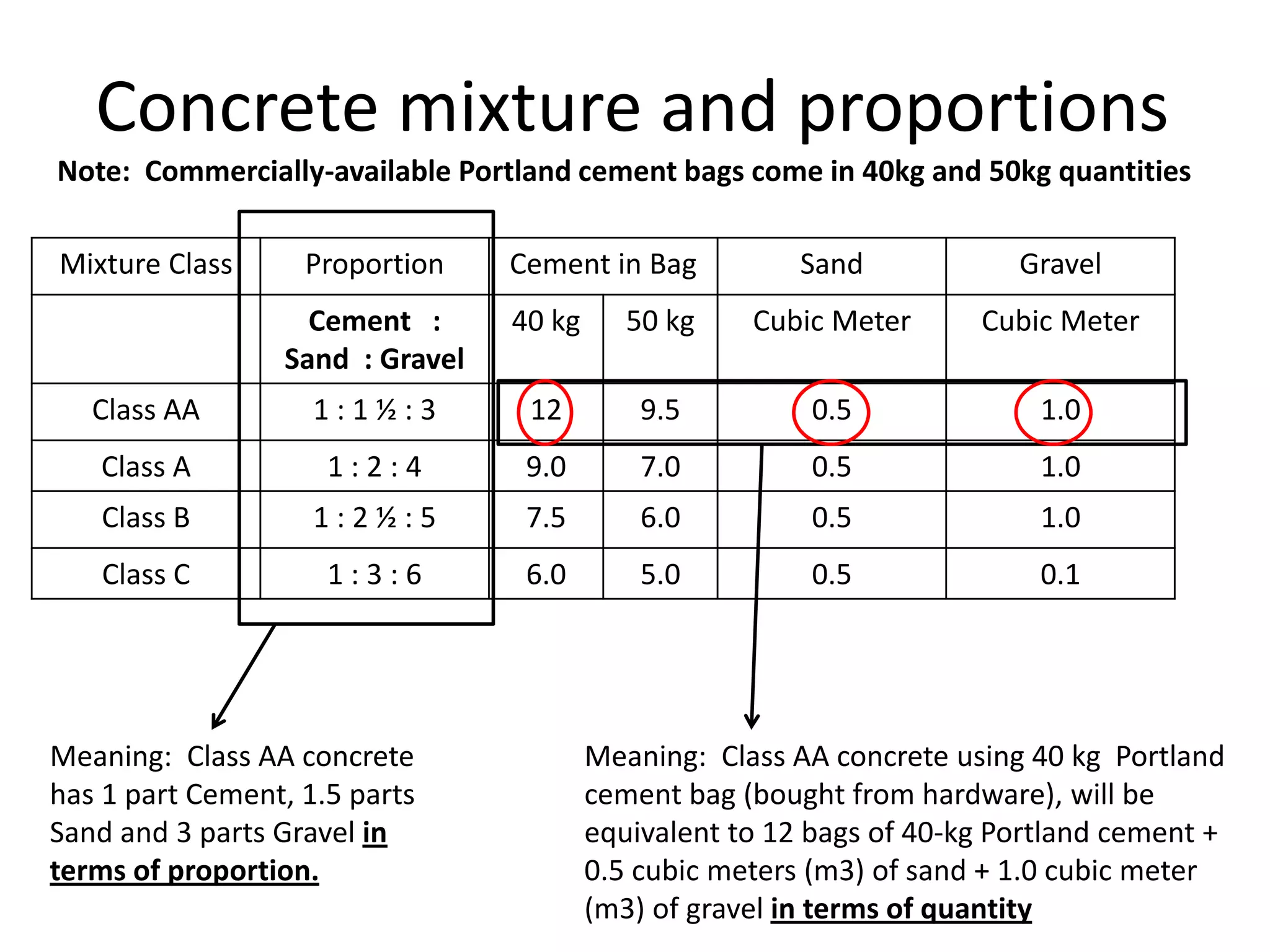

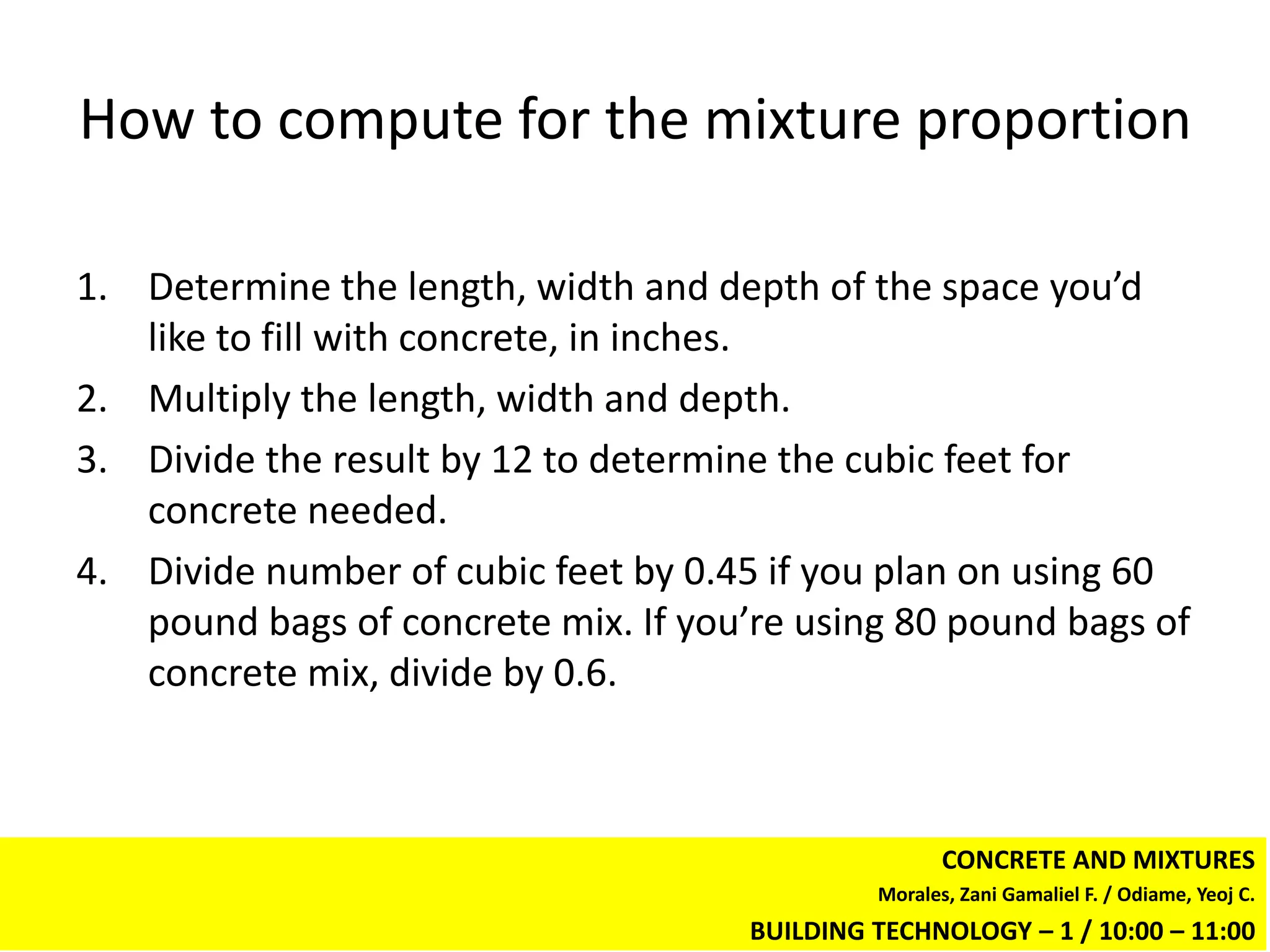

The document discusses the history and composition of concrete. It explains that modern concrete has greater compressive and tensile strength than ancient Roman concrete due to the use of Portland cement and steel reinforcement. The document also outlines different concrete mixtures based on proportion ratios and their recommended uses. It provides methods for calculating concrete needs and differentiates between concrete, cement, grout, and plaster.