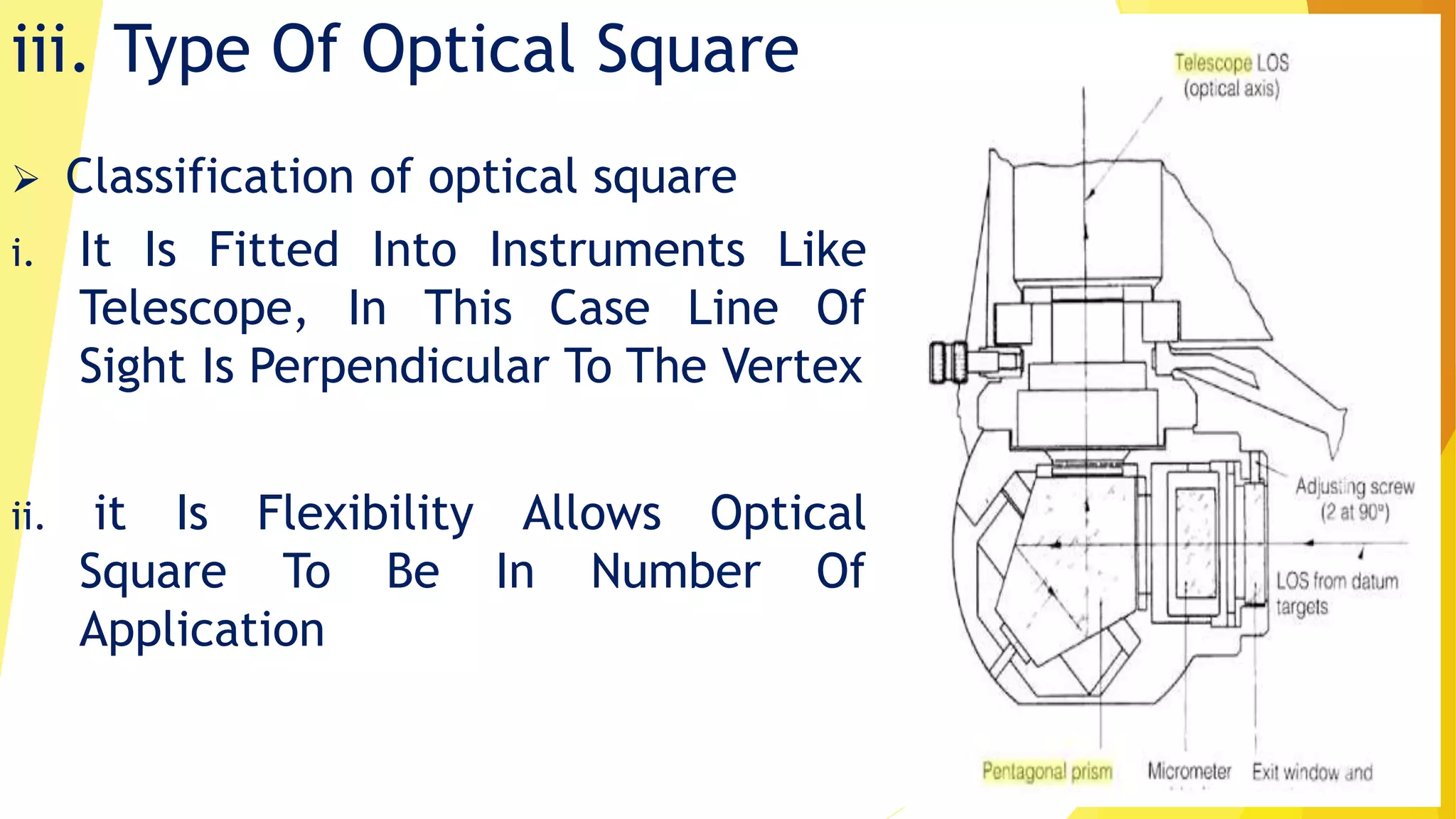

This document discusses optical flats and optical squares. It defines them as precision instruments used for measurement and alignment. Optical squares use the principle of double reflection to turn a line of sight by 90 degrees, while optical flats have two highly polished, flat surfaces used to test the flatness of other precision surfaces by observing interference patterns. The document describes the different types of optical squares and flats and their uses in measurement applications like surveying.