This document summarizes information about welded joints from an active learning assignment. It includes:

1) An introduction to welded joints, defining welding as a process of joining metallic parts through heating and fusion.

2) Advantages of welded joints like higher efficiency, lighter weight, and flexibility in welding procedures.

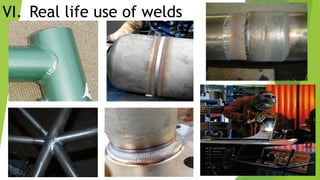

3) Limitations of welded joints including poorer vibration resistance and inability to join different materials. Examples of welded machine components are also given.

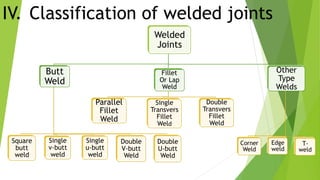

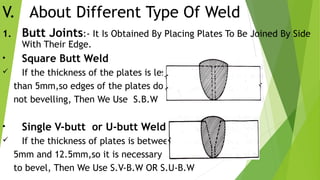

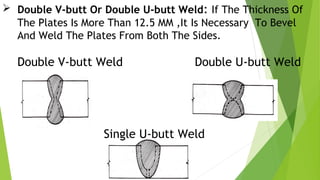

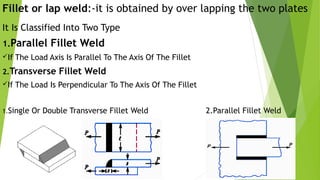

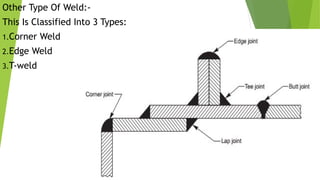

4) An overview of different types of welded joints like butt joints, fillet welds, corner welds, and T-welds.