This document provides information on various operations management concepts including plant location, plant layout, production methods, work study, and work measurement techniques.

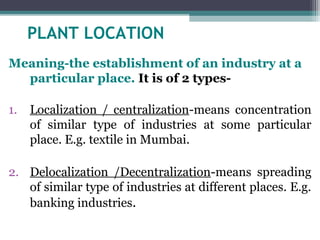

It discusses factors that affect plant location and site selection such as availability of raw materials, labor, and transportation. It also describes different types of plant layouts including product, process, and combination layouts.

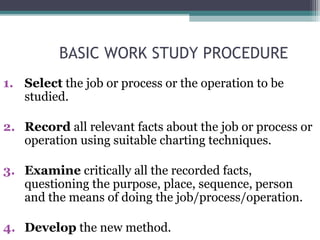

The document outlines various production methods like job production, batch production, and mass production. It then covers work study concepts including method study, motion study, and time study. Finally, it summarizes several work measurement techniques used to establish standard times like direct time study, predetermined motion time study, and synthesis method.