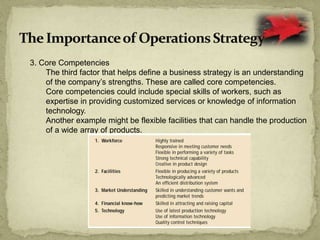

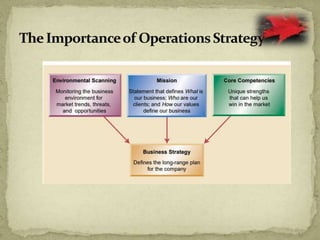

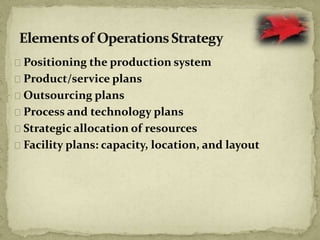

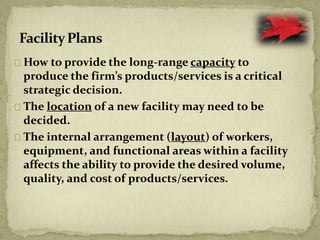

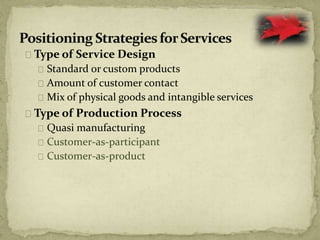

The document discusses operations strategy and competitiveness. It explains that operations strategy provides a plan for how the operations function will use resources to support the company's competitive strategy. This includes decisions about facilities, worker skills, technology use, processes, equipment, and quality control. The operations strategy is developed based on the company's competitive priorities of cost, quality, time, and flexibility.