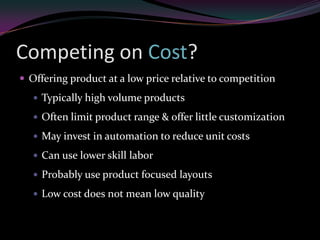

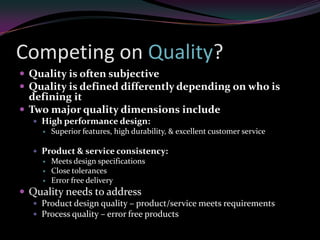

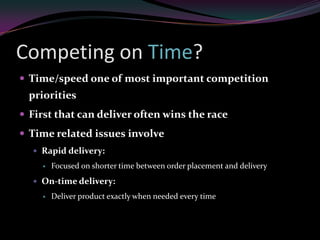

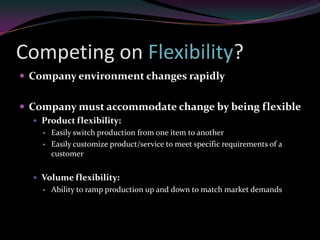

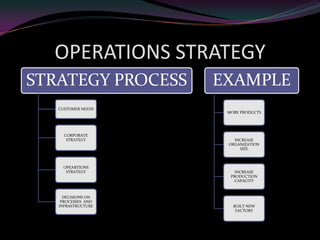

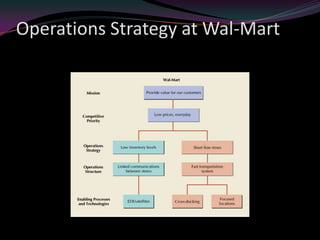

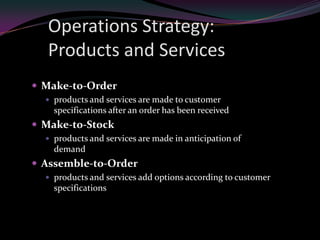

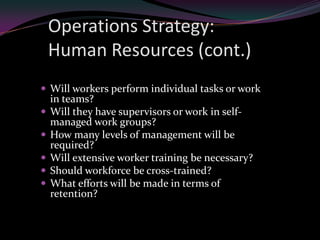

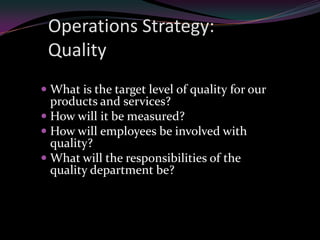

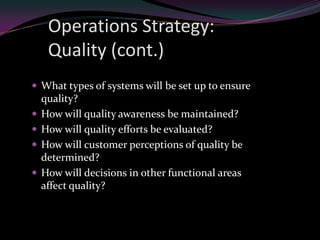

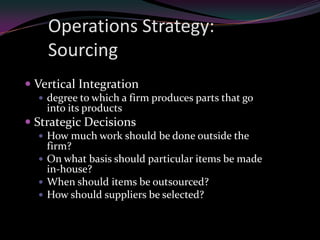

The document discusses operational strategies. It explains that operations deals with day-to-day processes of manufacturing goods while strategy deals with the long-term direction of an organization. Key operational priorities include competing based on cost, quality, time, and flexibility. Developing an effective operations strategy involves determining production levels, facility locations, technology use, and supplier relationships in a way that supports the overall corporate strategy.