This standard lays out fire protection requirements for petroleum depots, terminals, and pipeline installations. Key requirements include:

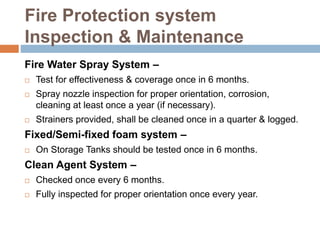

- Installation of fixed water spray systems on certain above-ground storage tanks.

- Provision of clean agent flooding systems for control rooms.

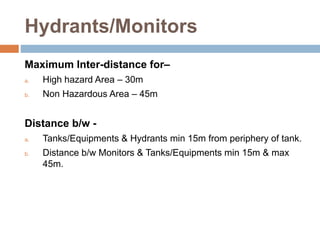

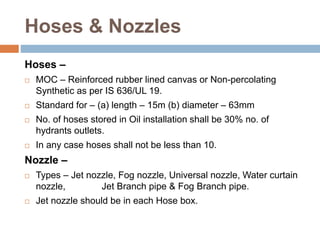

- Hydrants and monitors spaced a maximum of 30m apart.

- Sufficient firewater storage for 4 hours at the design pump rate. Storage should be in two equal interconnected compartments.

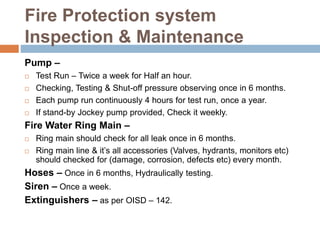

- Multiple diesel-engine firewater pumps, with capacity for 150% of the rated flow. At least one standby pump is required.

- A jockey pump to maintain system pressure and at least one standby j