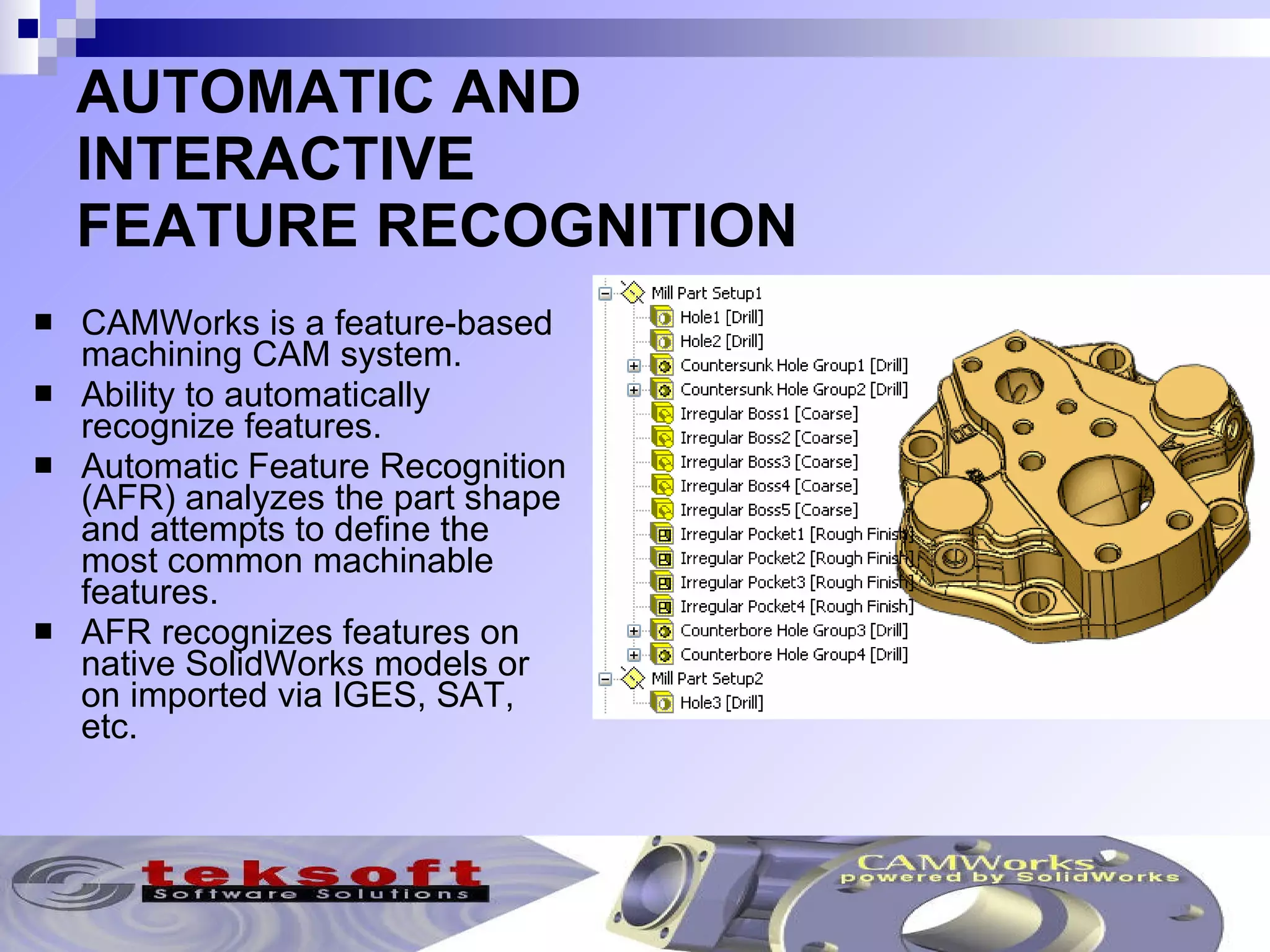

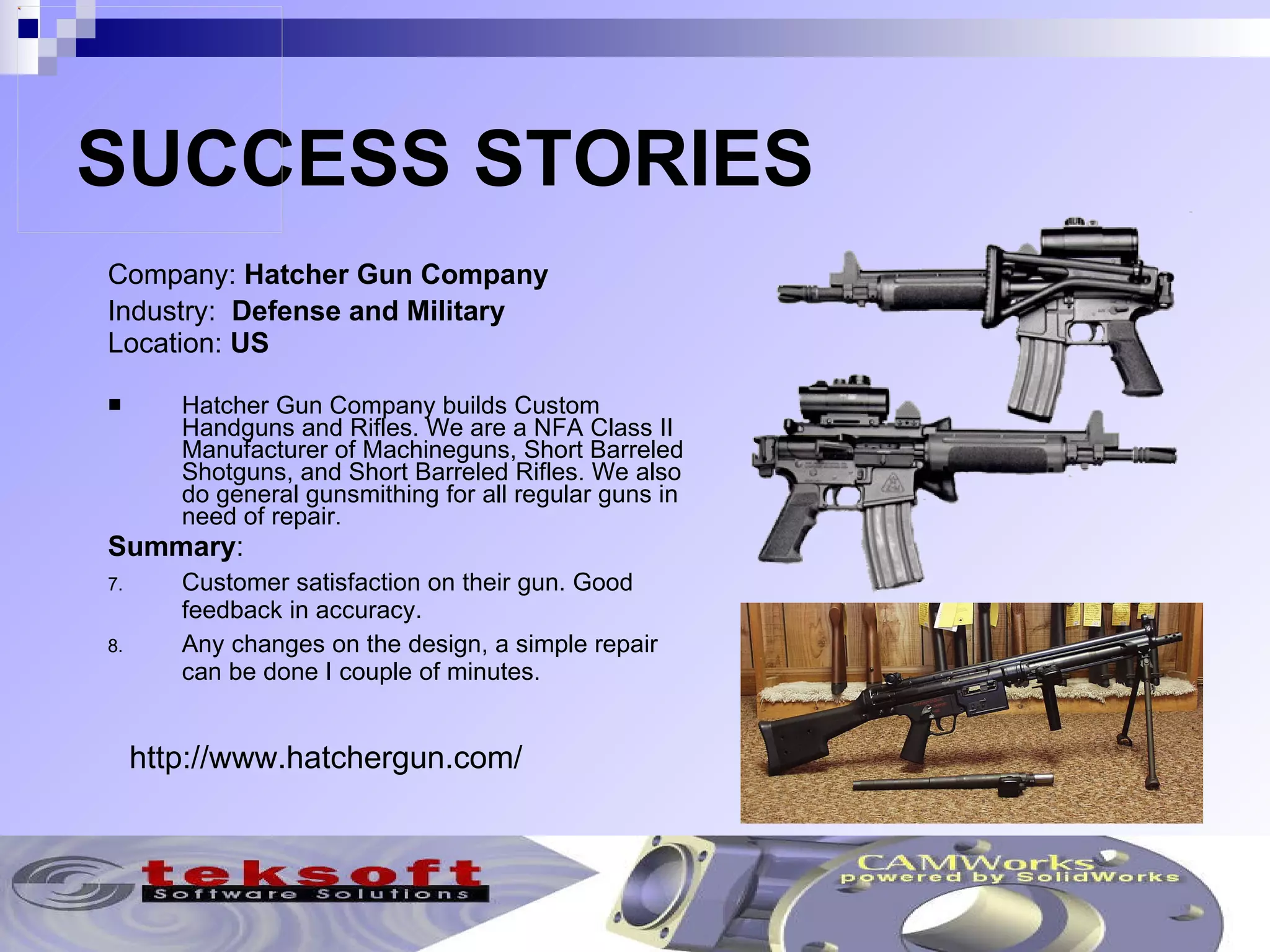

CAMWorks is an advanced CAM software tool that provides automated and intelligent machining capabilities. It uses familiar SolidWorks interfaces and automatically recognizes features to generate toolpaths. CAMWorks integrates with SolidWorks for optimum modeling and is used by customers in industries like mold making, aerospace and automotive. It allows for faster machining and decreased design time through automated features.