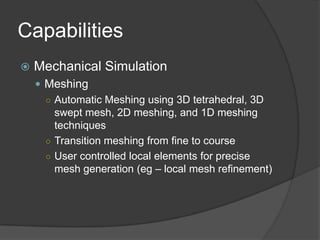

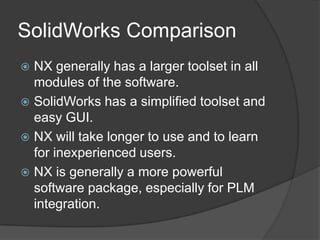

The document summarizes UGS NX by Siemens, a CAD/CAM/CAE software. It provides an agenda that introduces NX, lists common users in mechanical and manufacturing industries, demonstrates a stress analysis, compares NX capabilities to SolidWorks, and ends with a question and answer section. Key capabilities of NX include mechanical design, simulation, drafting, assembly design, sheet metal design, and machining. It has various meshing, loading, and solver options for simulation.