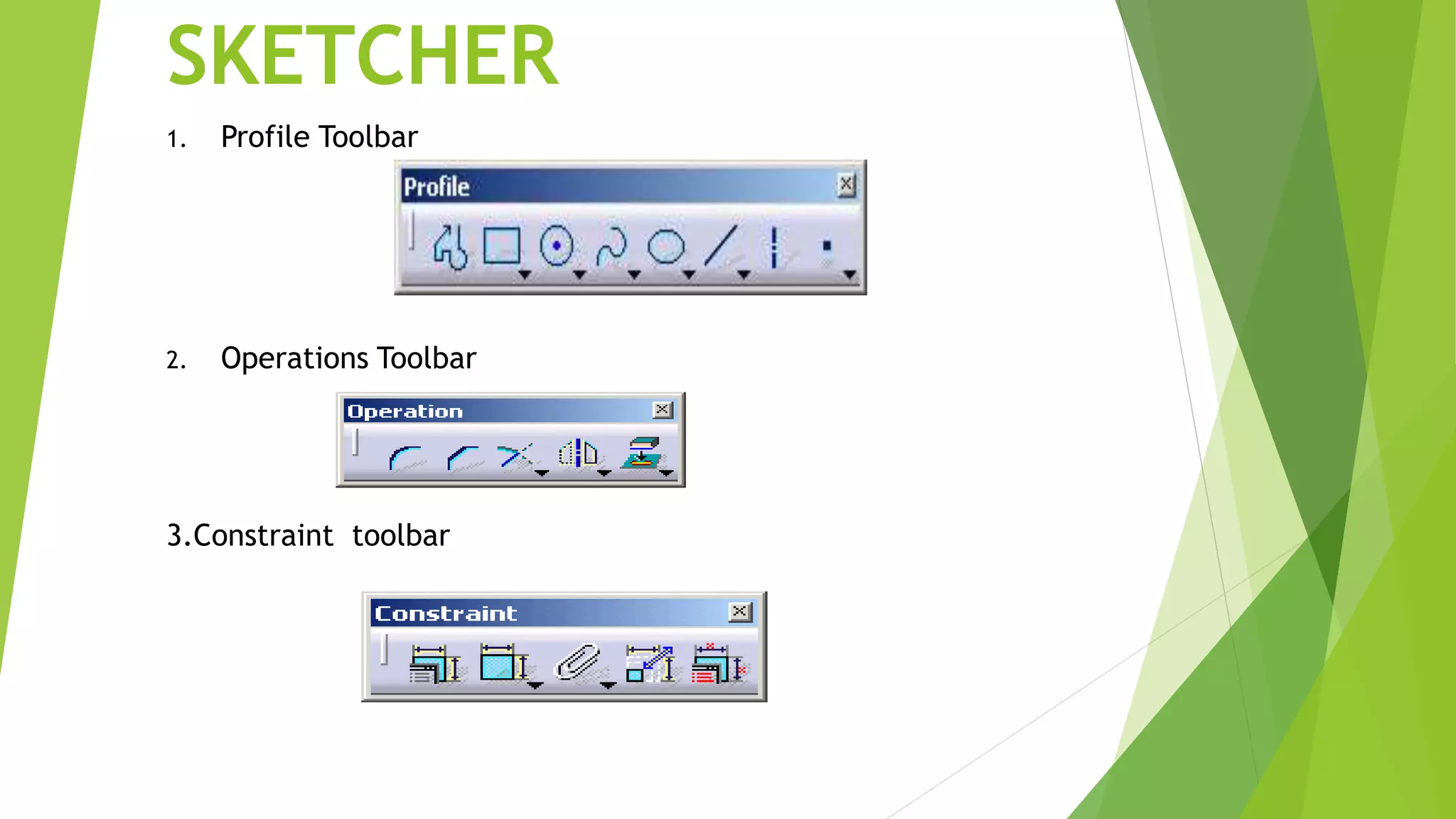

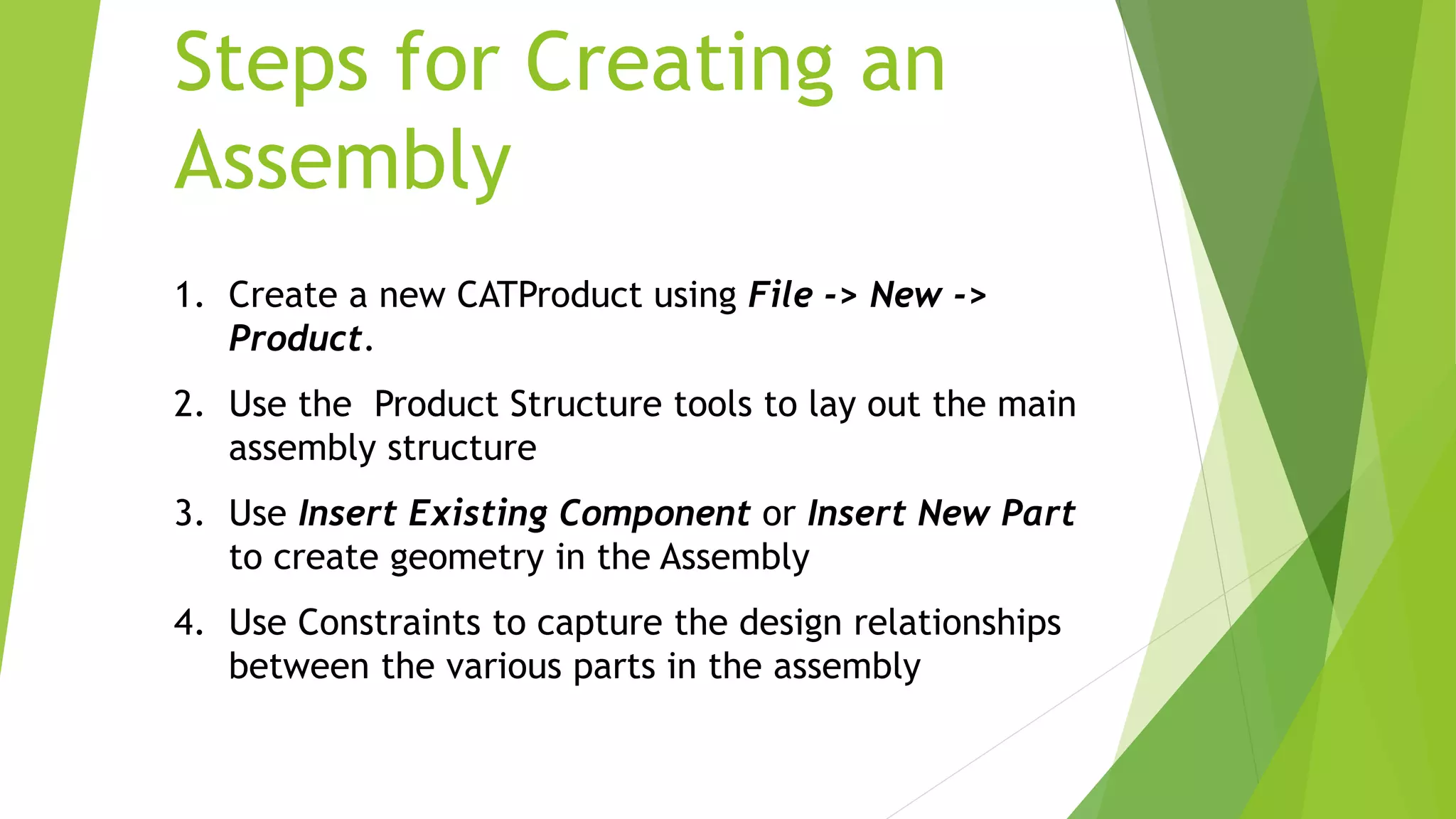

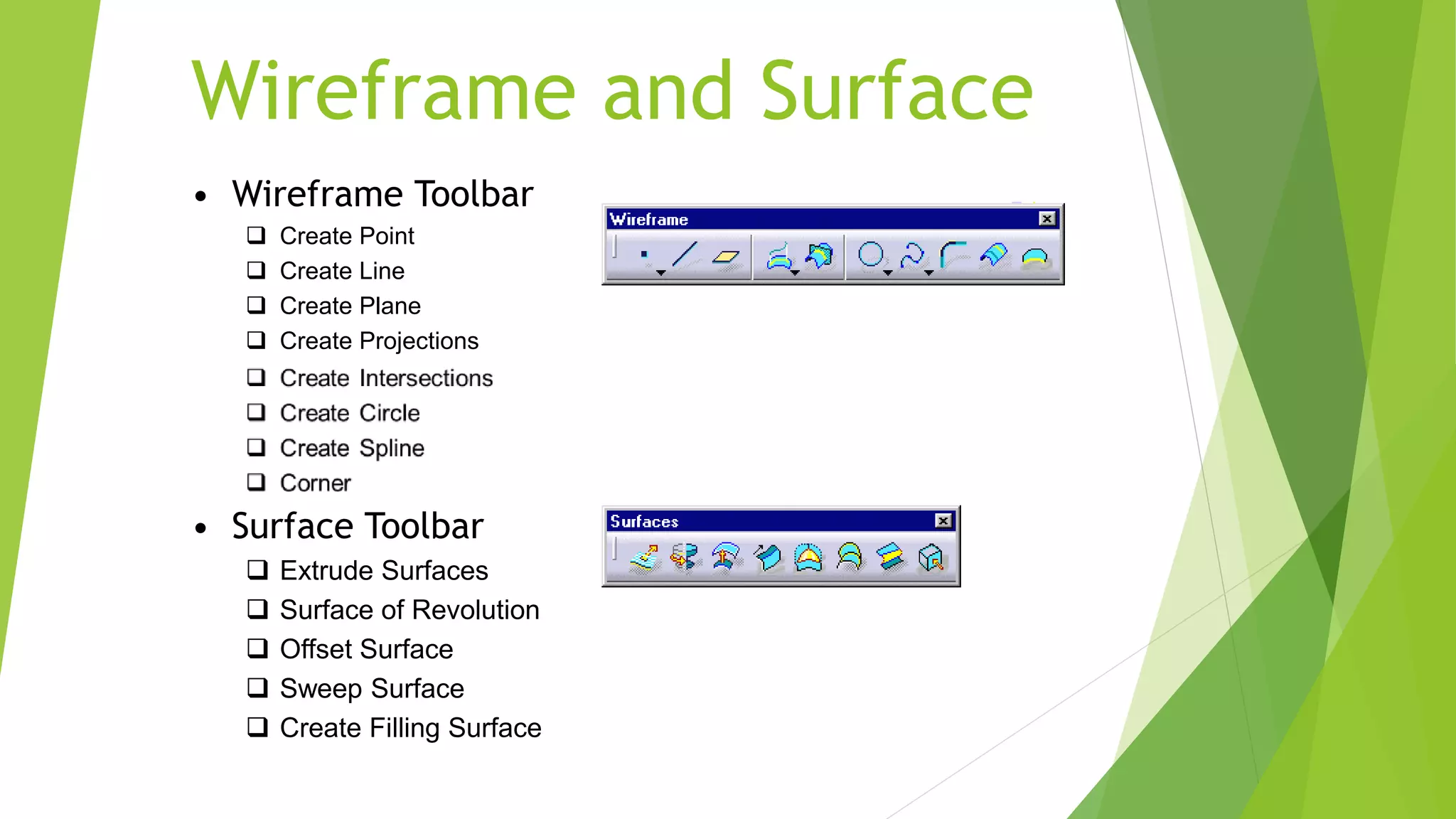

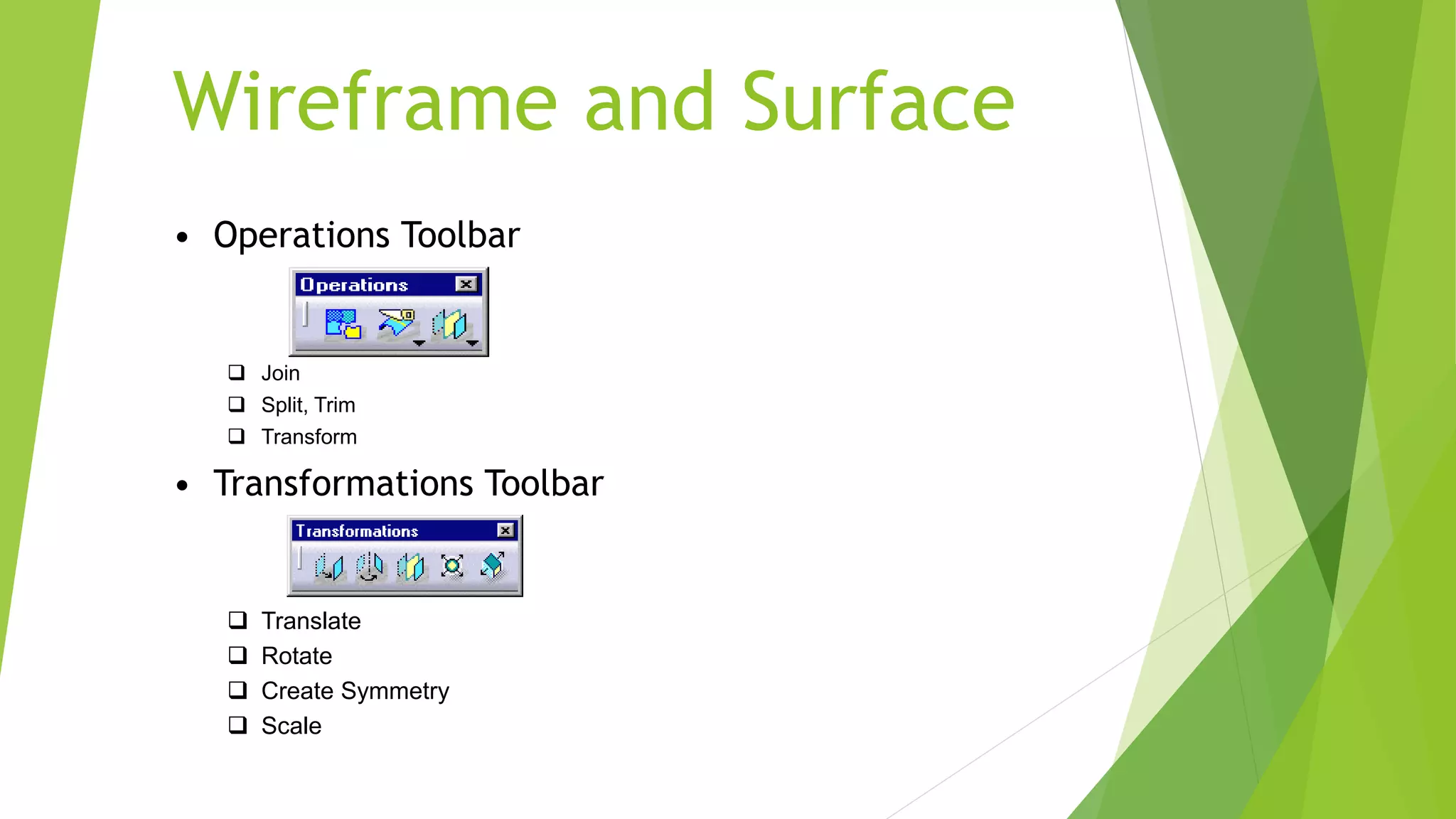

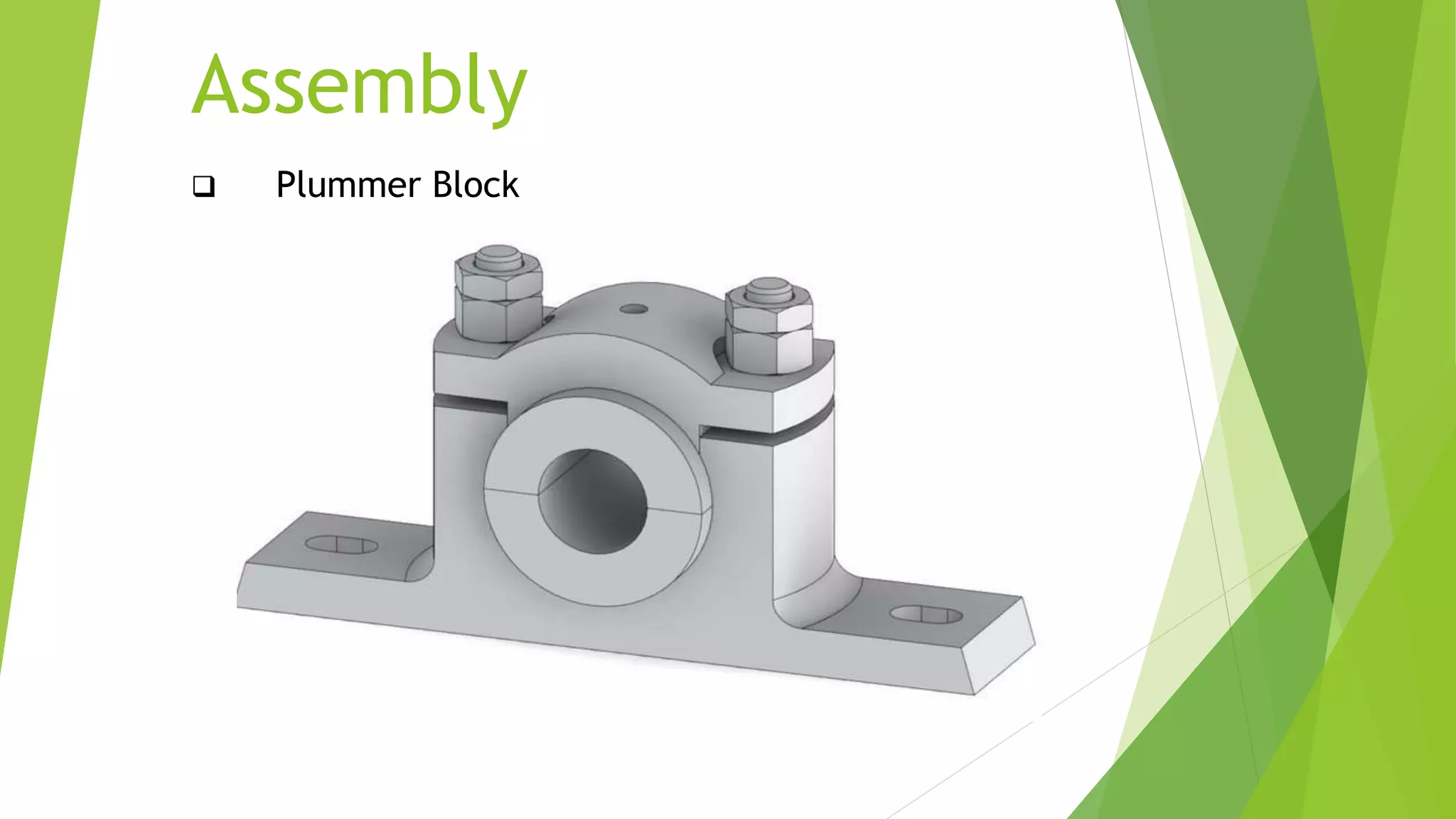

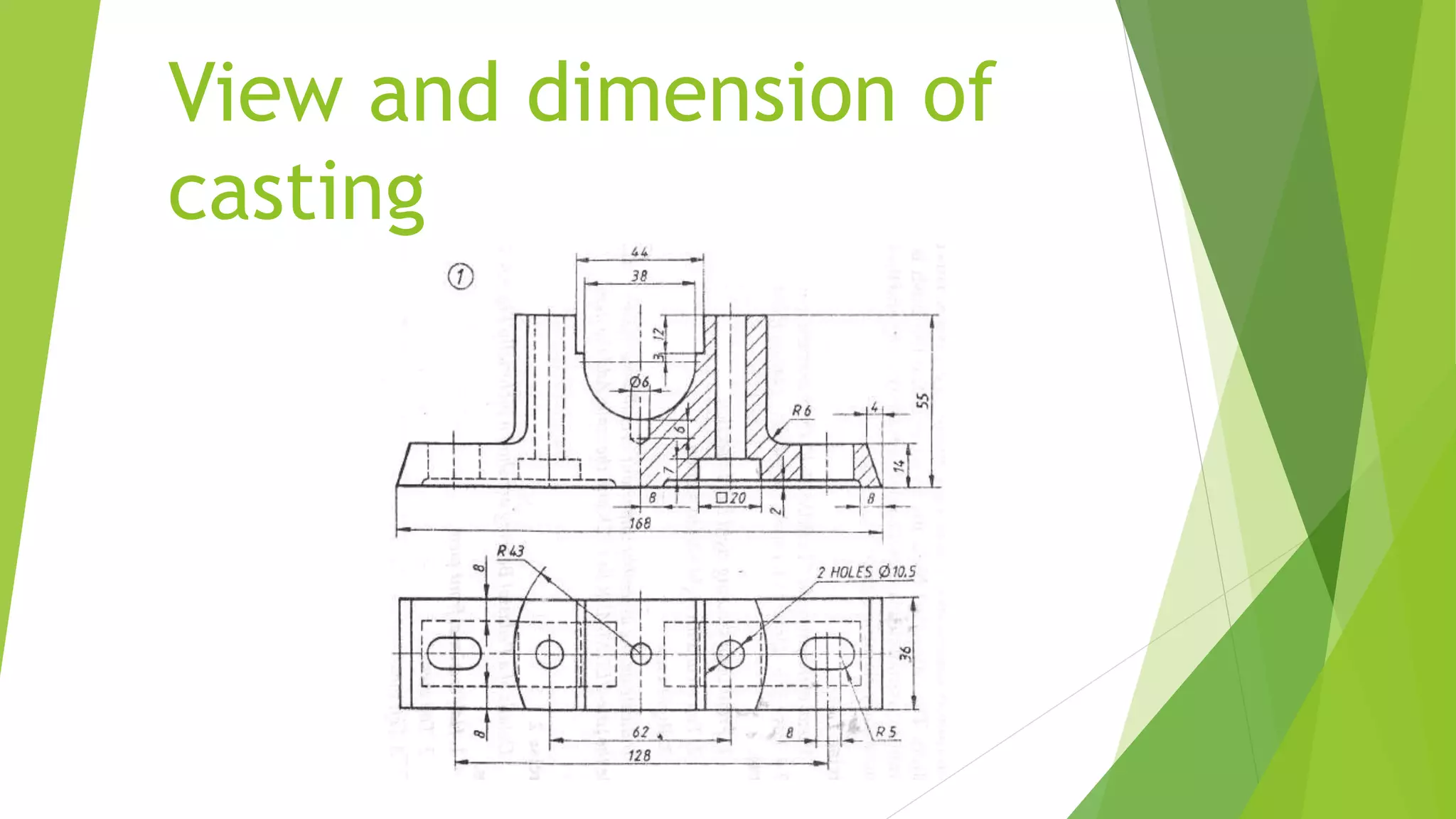

CATIA is a 3D CAD software created by Dassault Systèmes. It is used in industries like aerospace, automotive, and shipbuilding. CATIA allows users to create 3D models of parts and assemblies. It provides tools for sketching, part design, sheet metal design, and more. Key features include the specification tree to view a part's design history, assembly design tools to combine parts while defining relationships and constraints, and surface modeling tools for complex shapes.