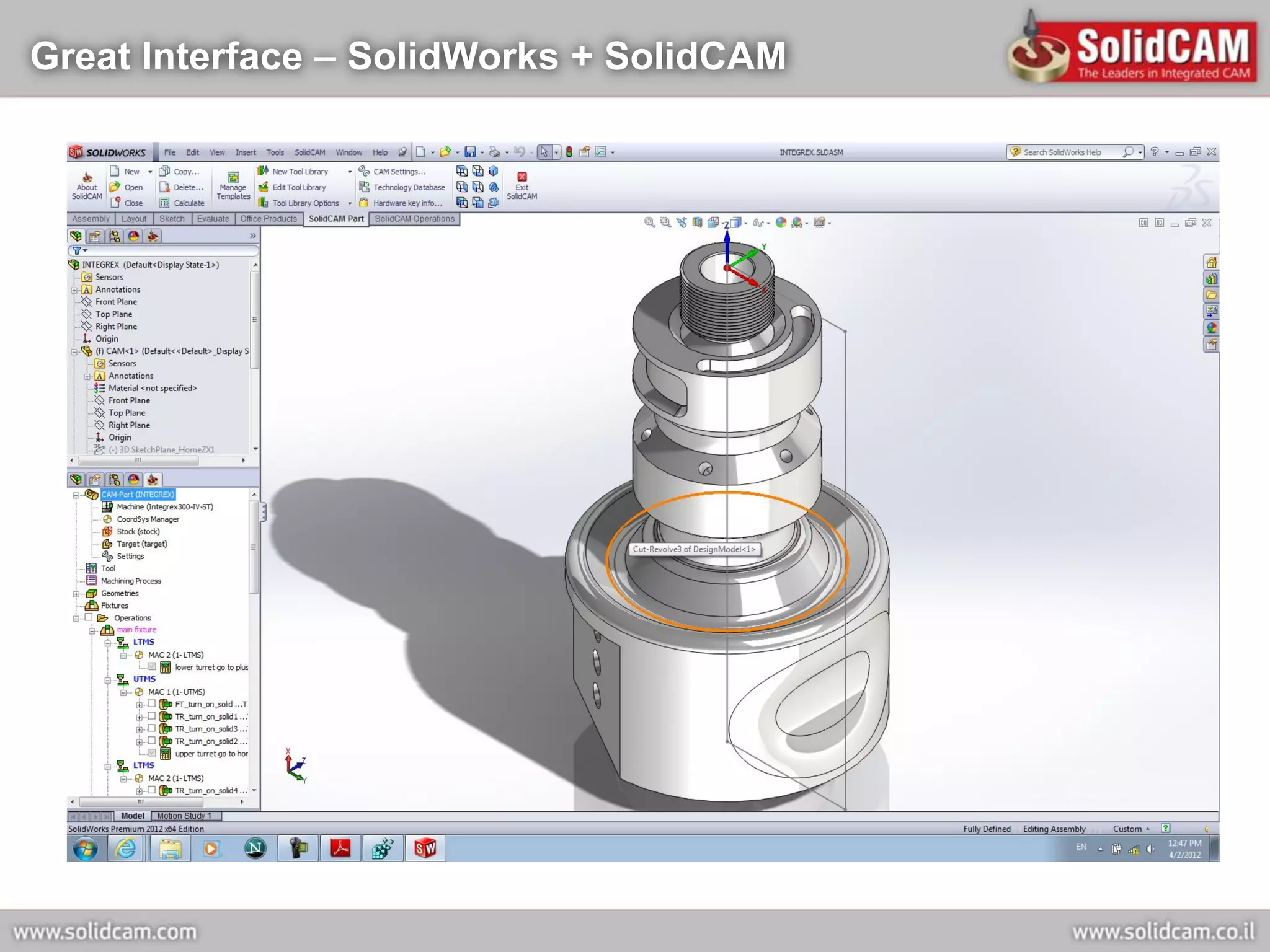

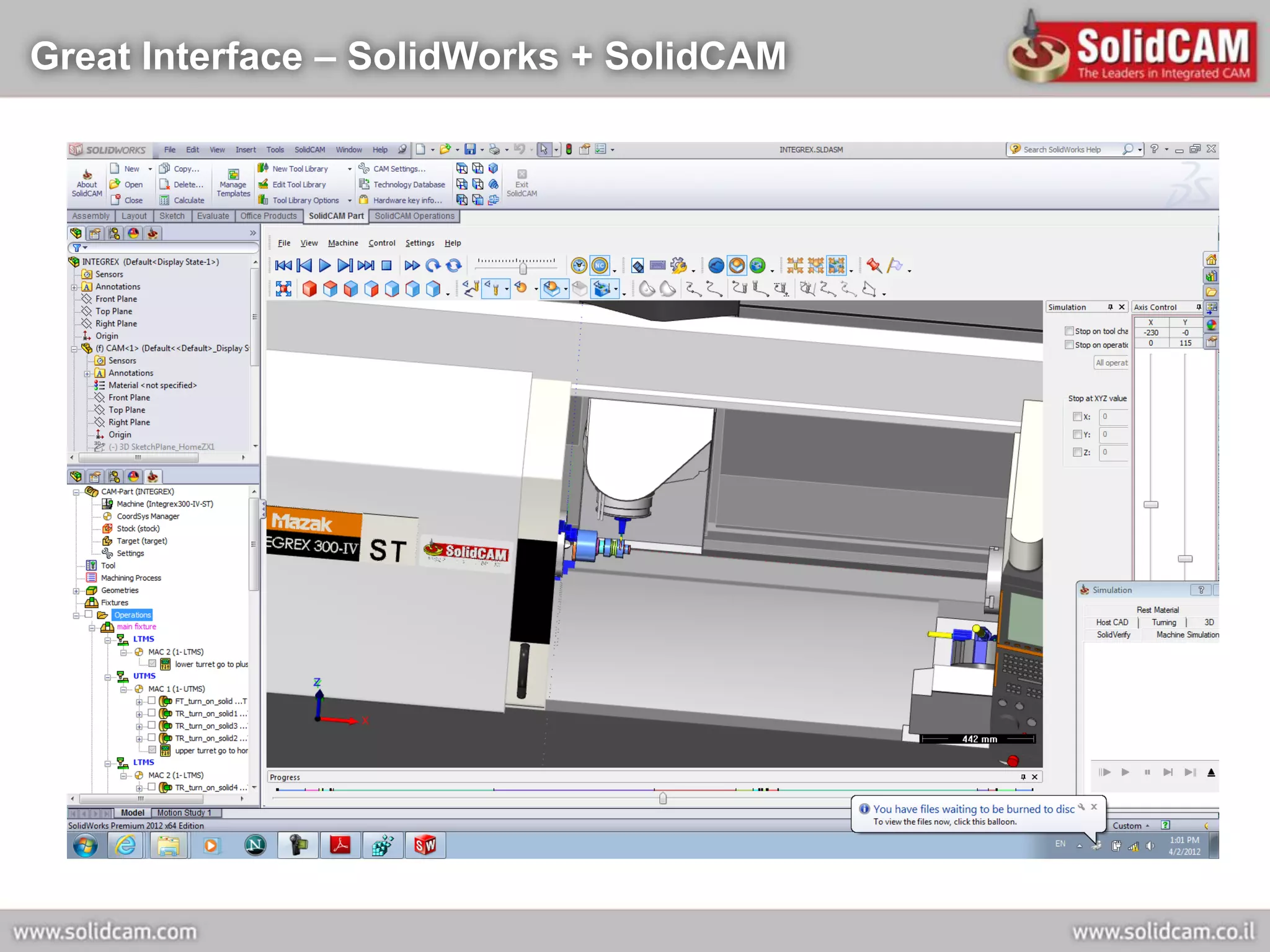

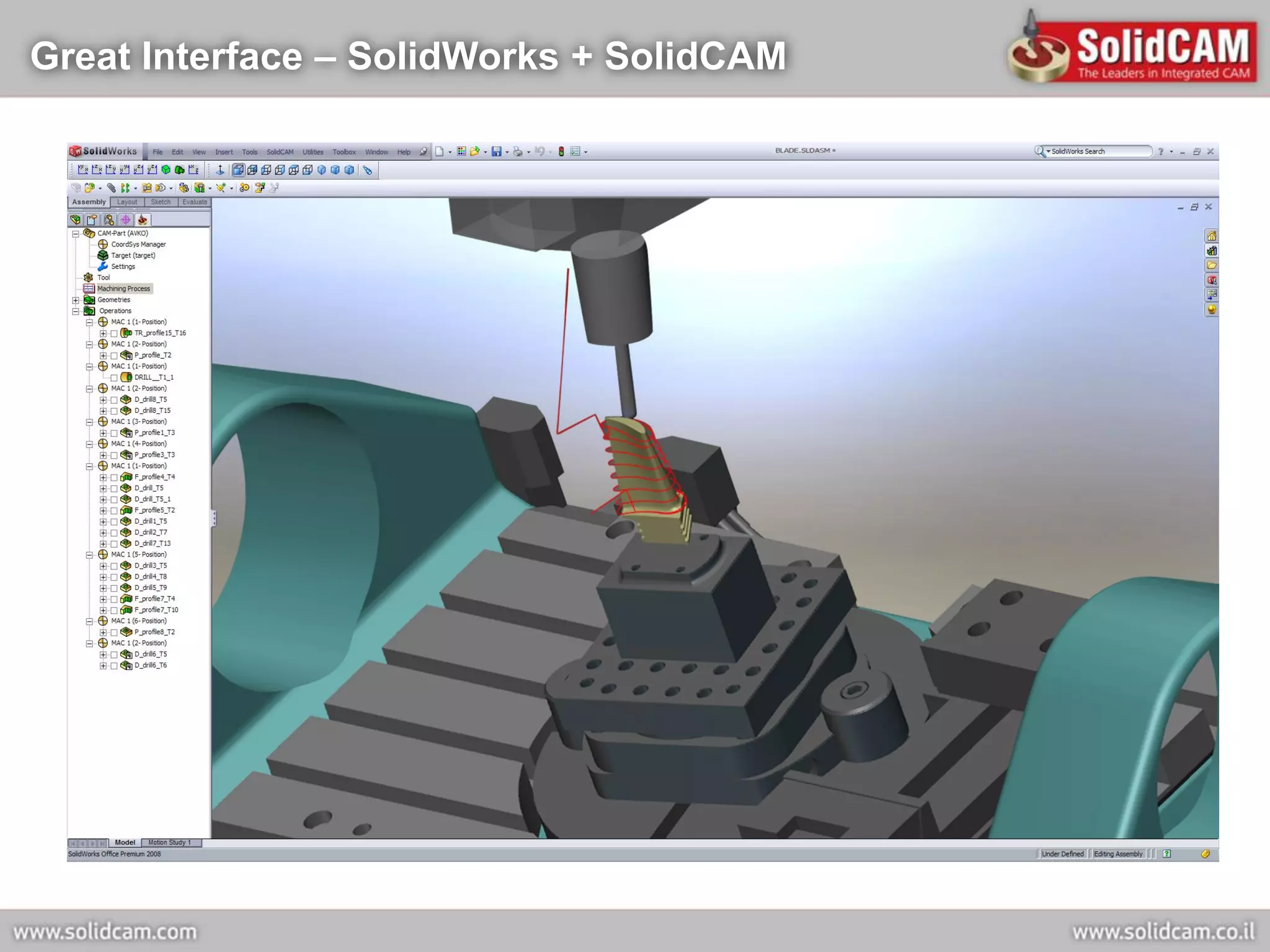

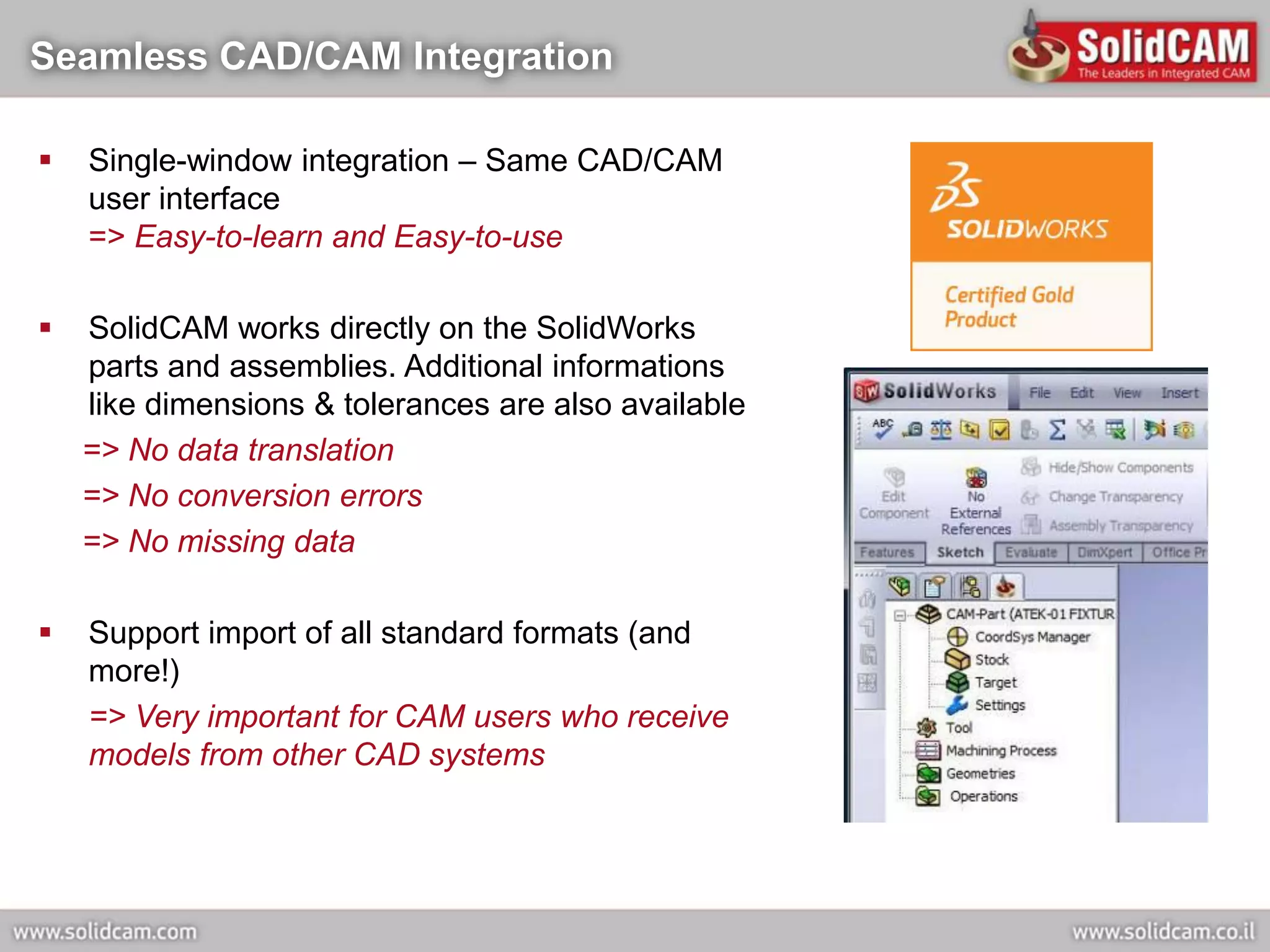

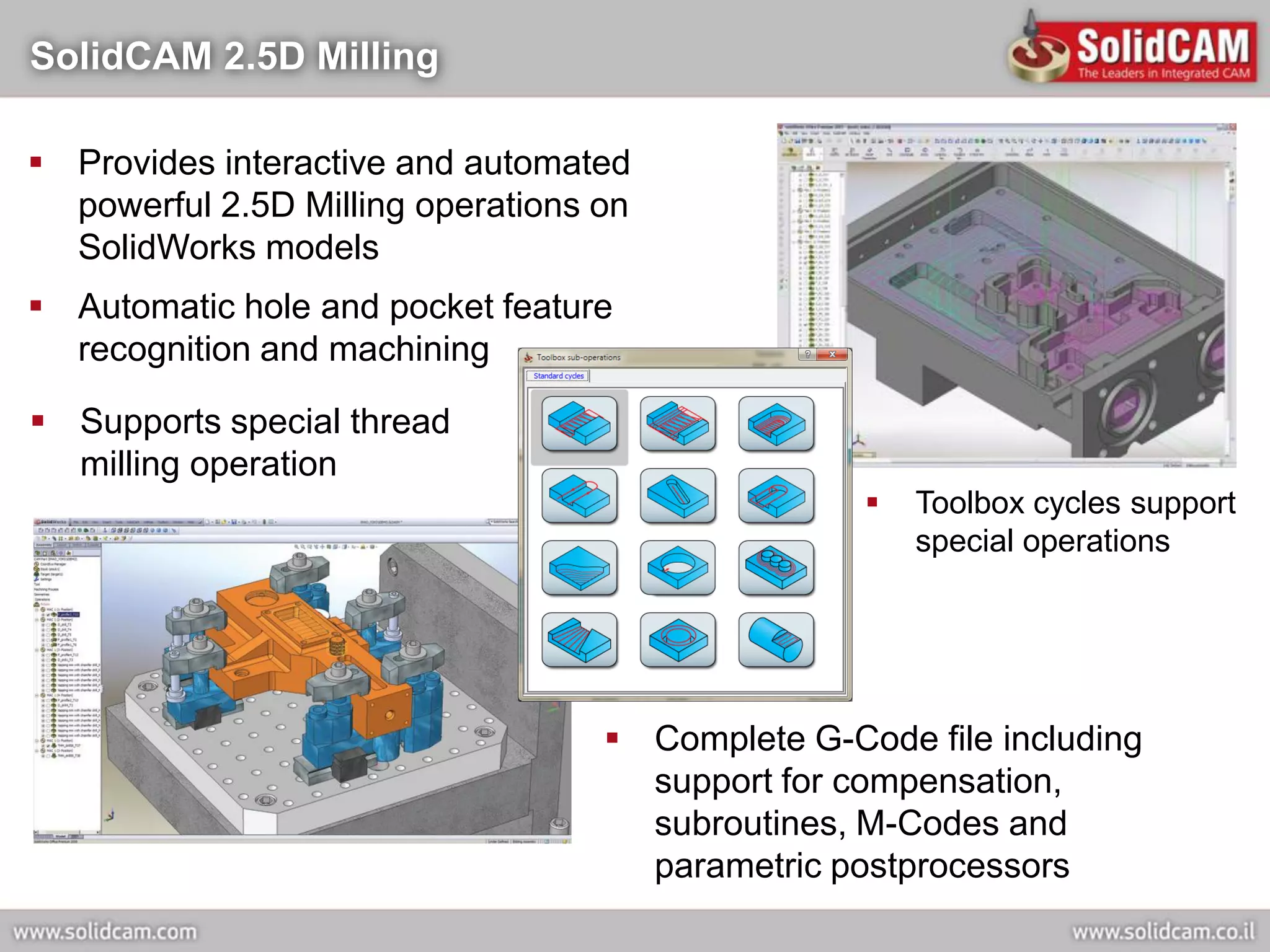

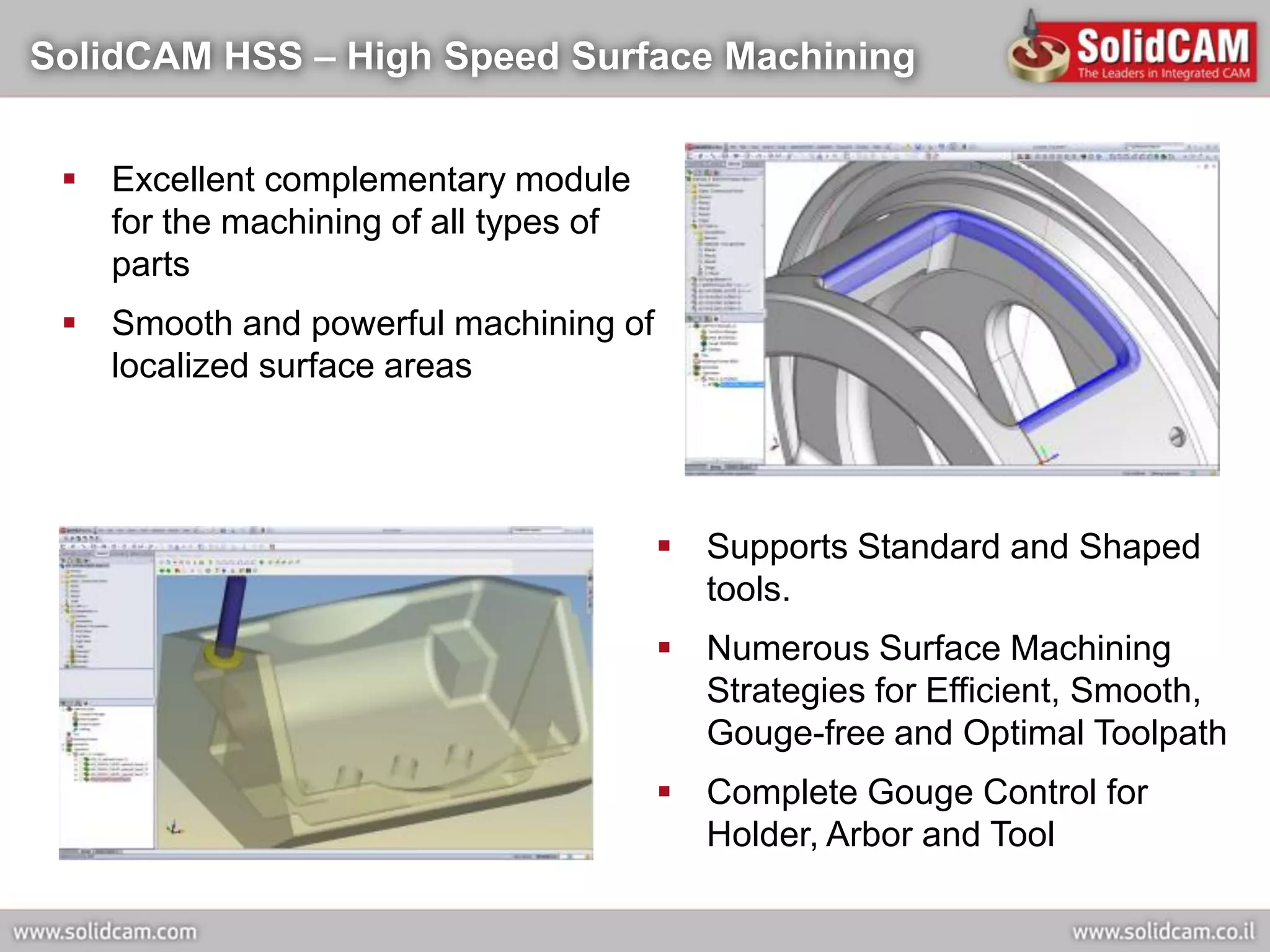

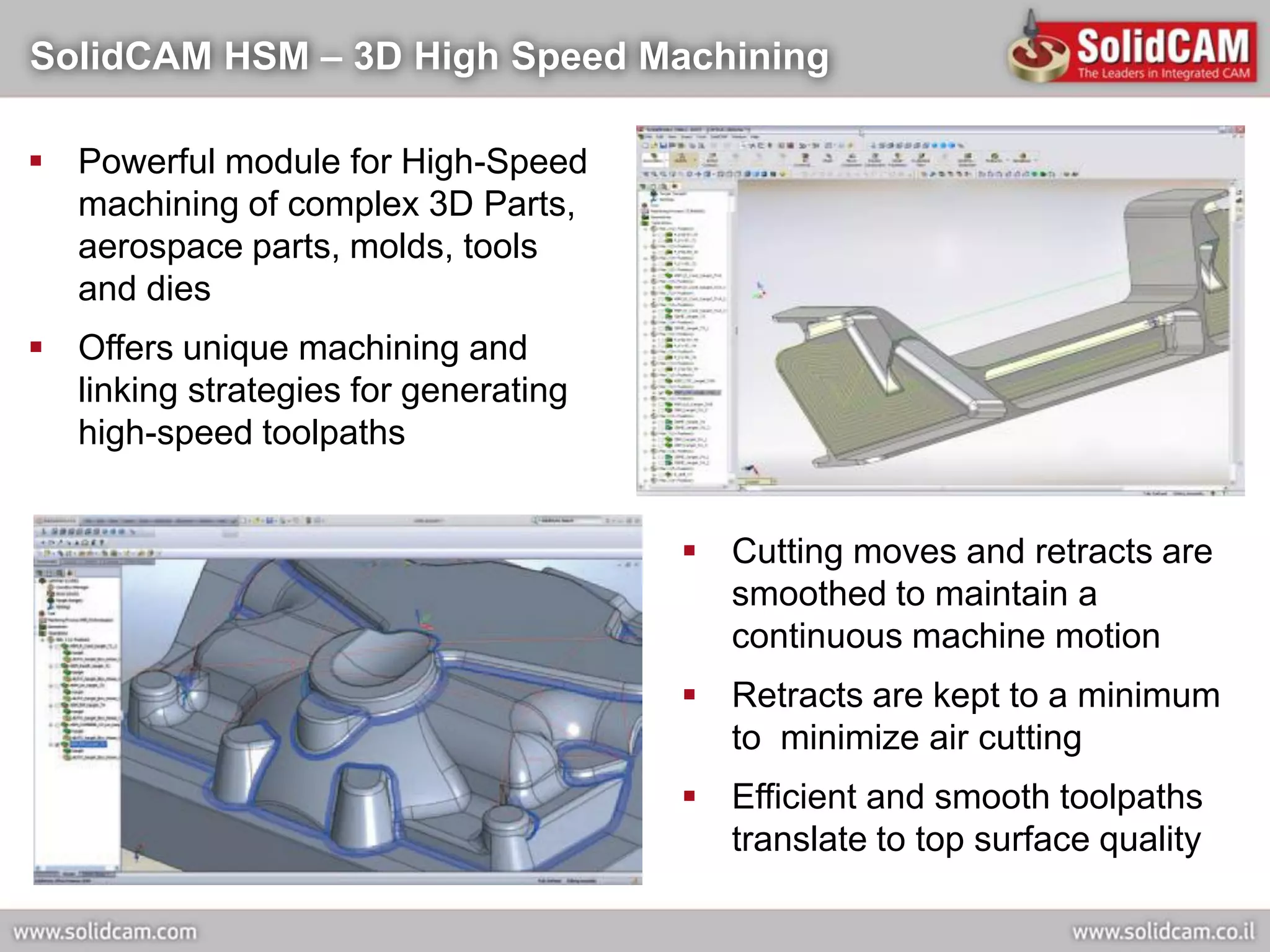

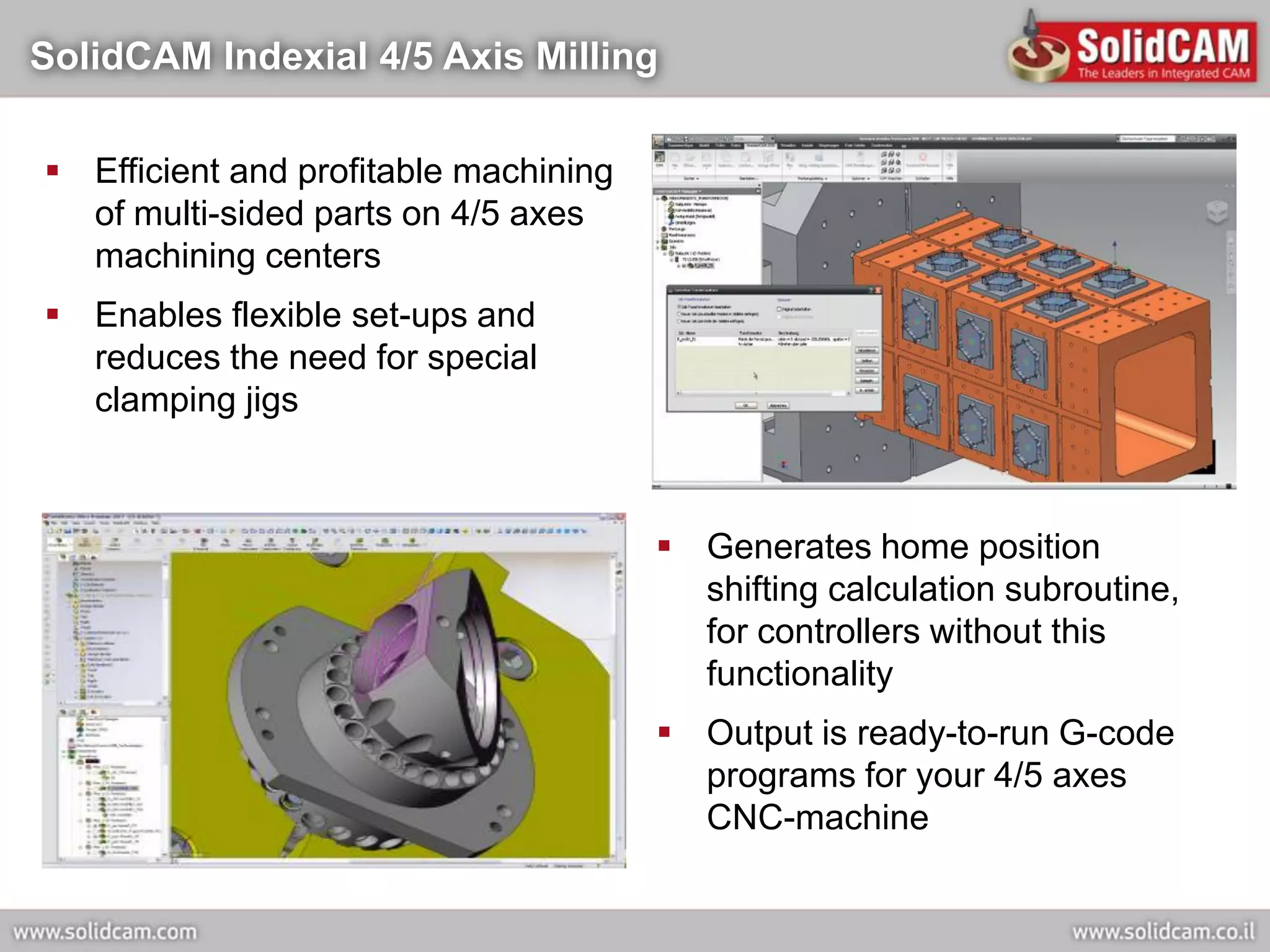

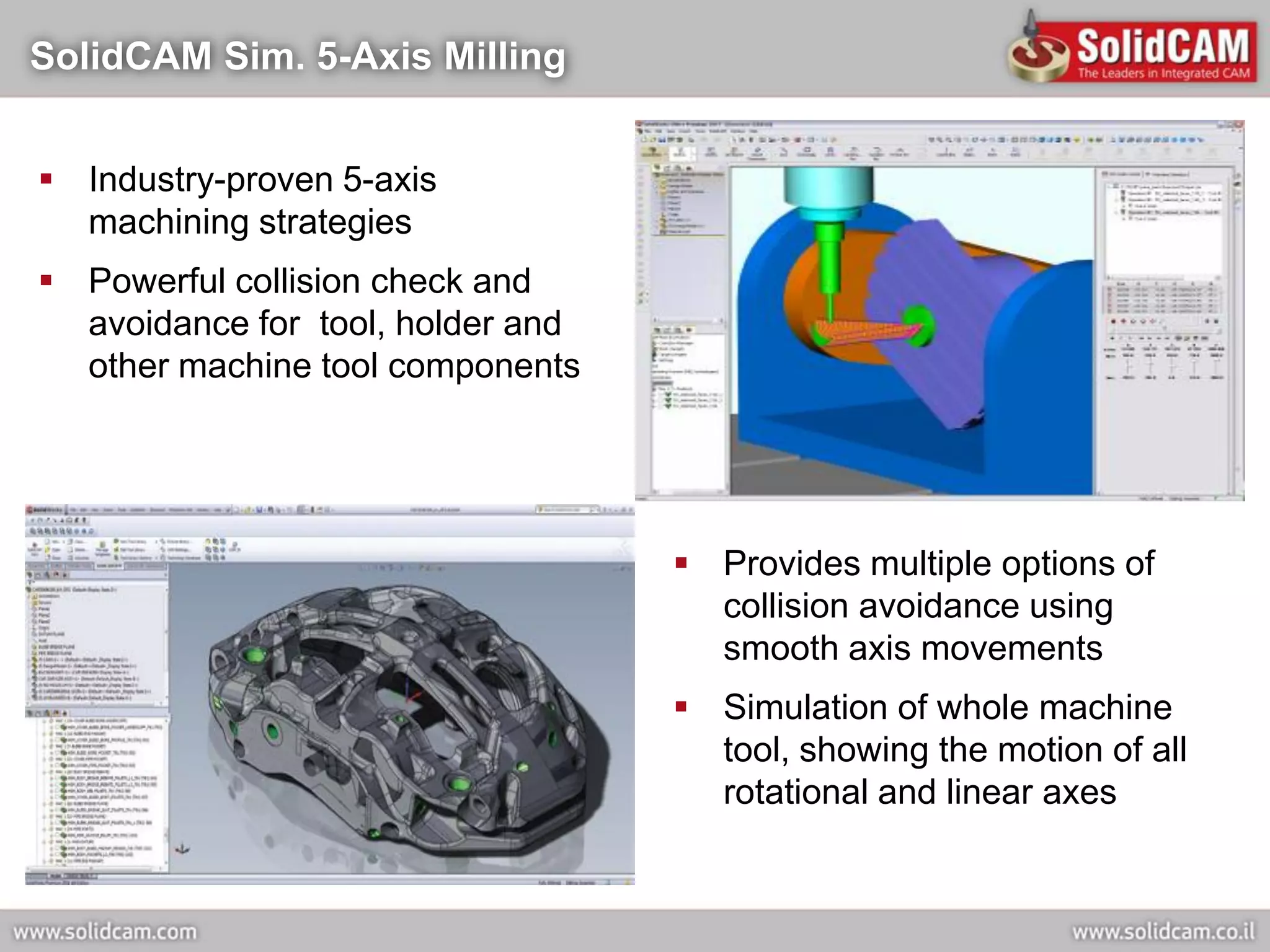

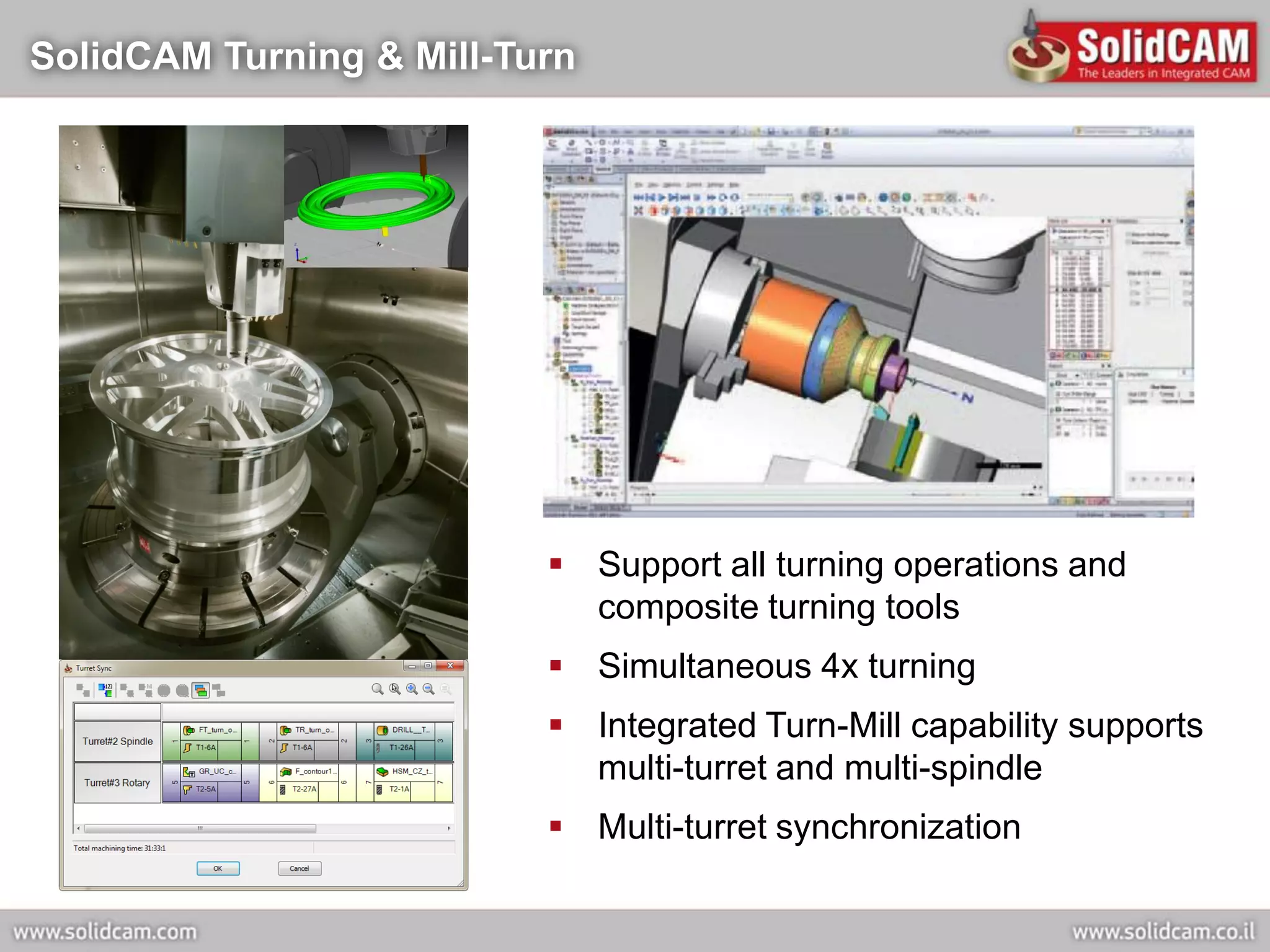

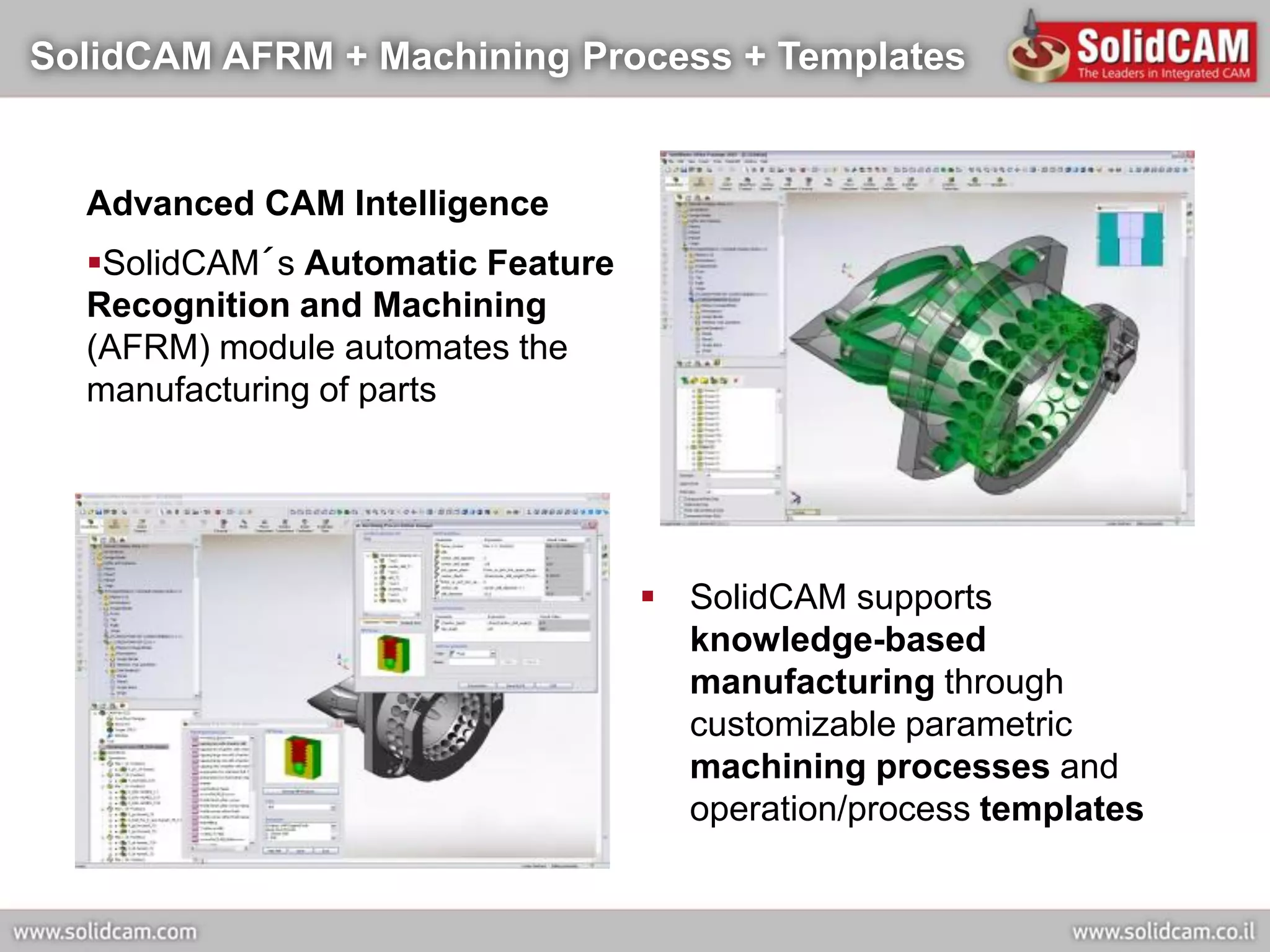

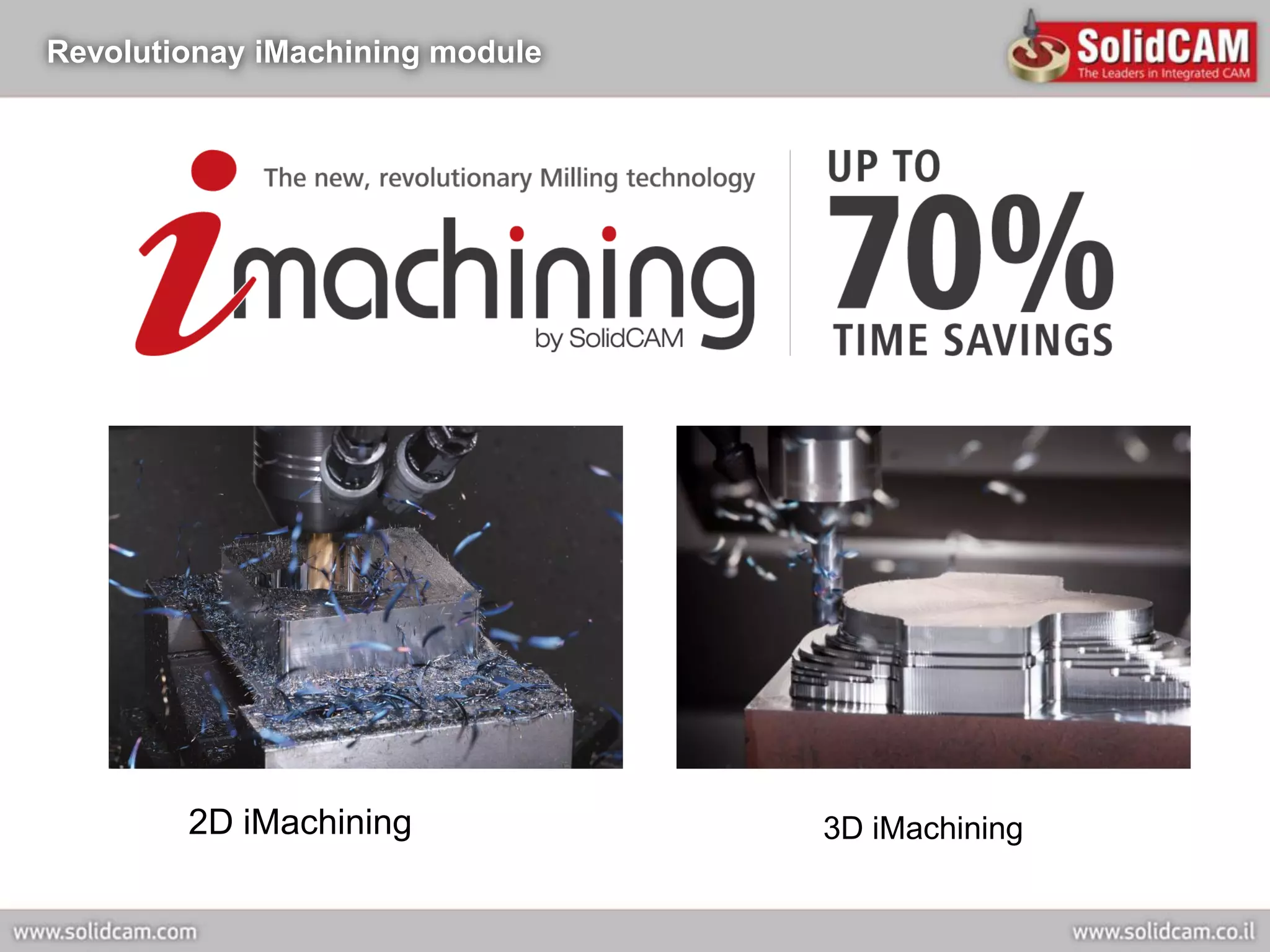

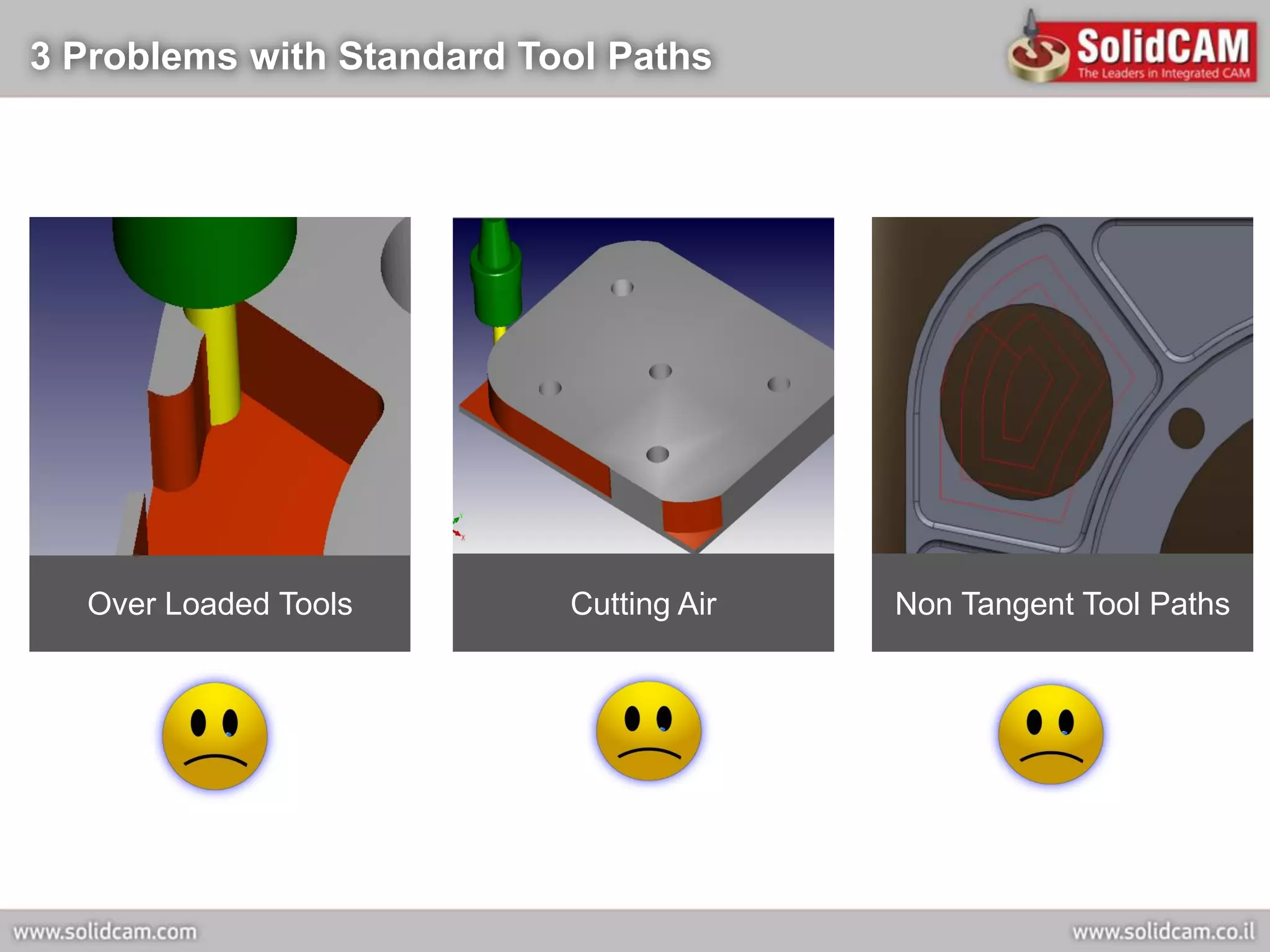

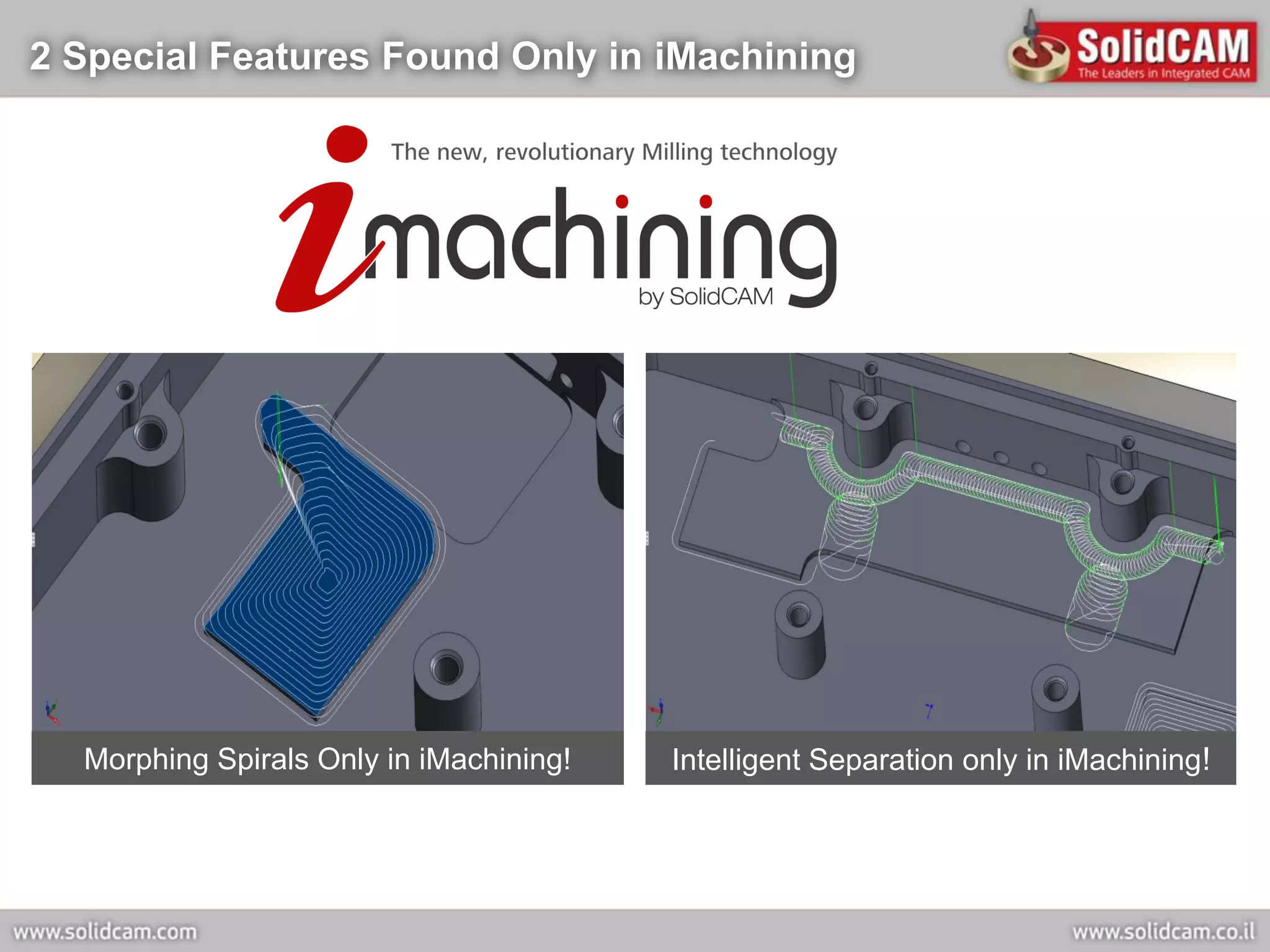

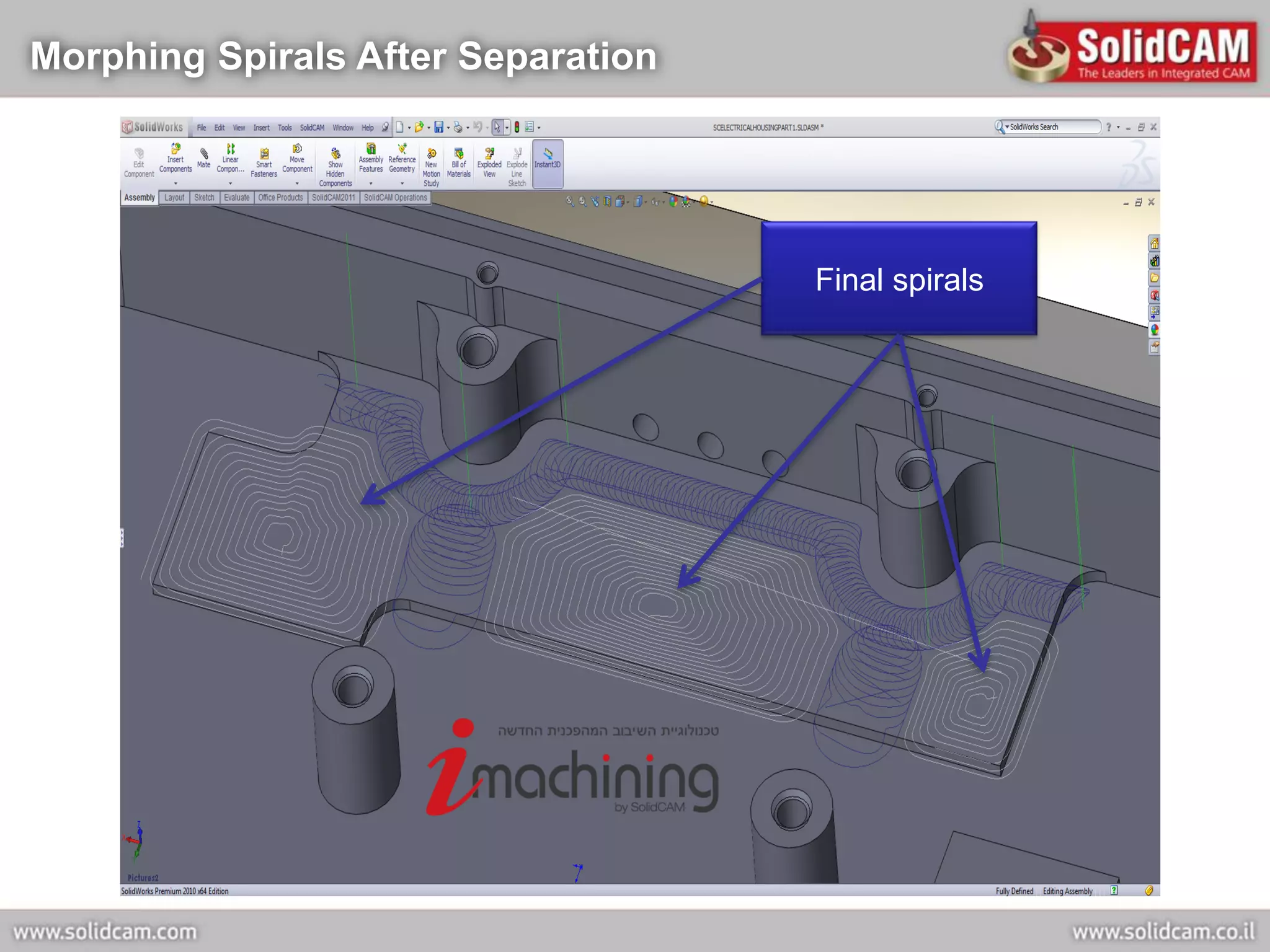

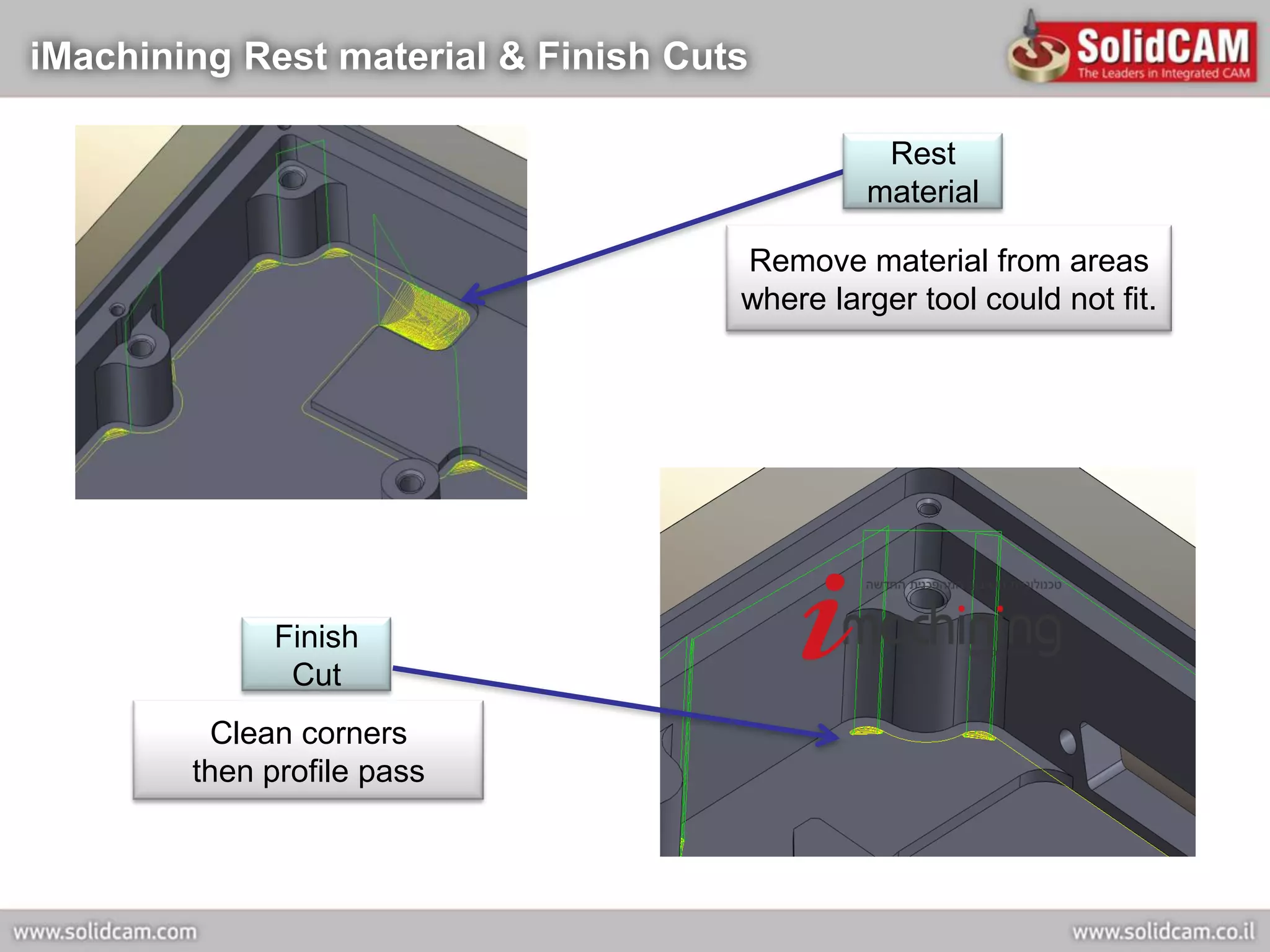

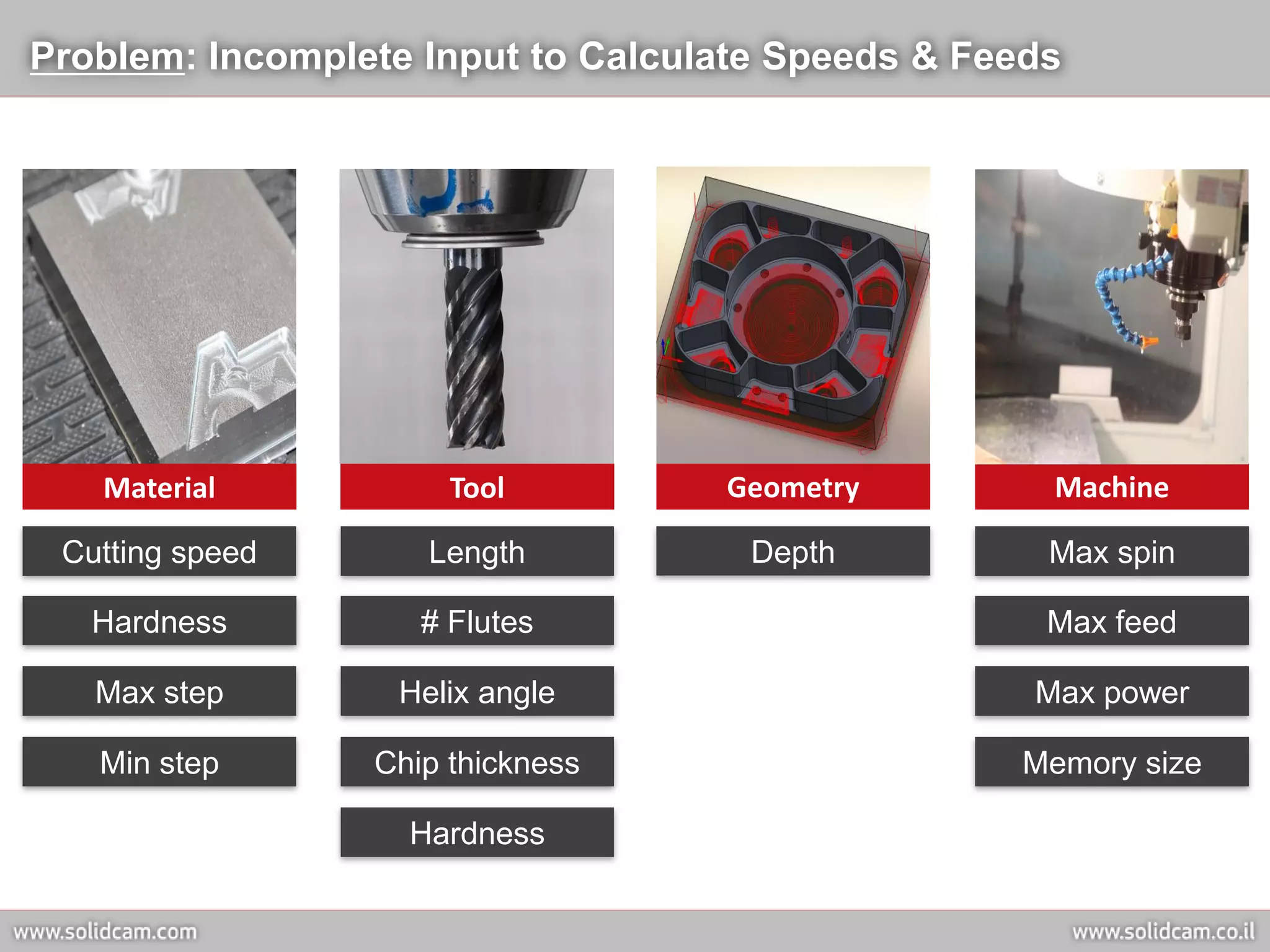

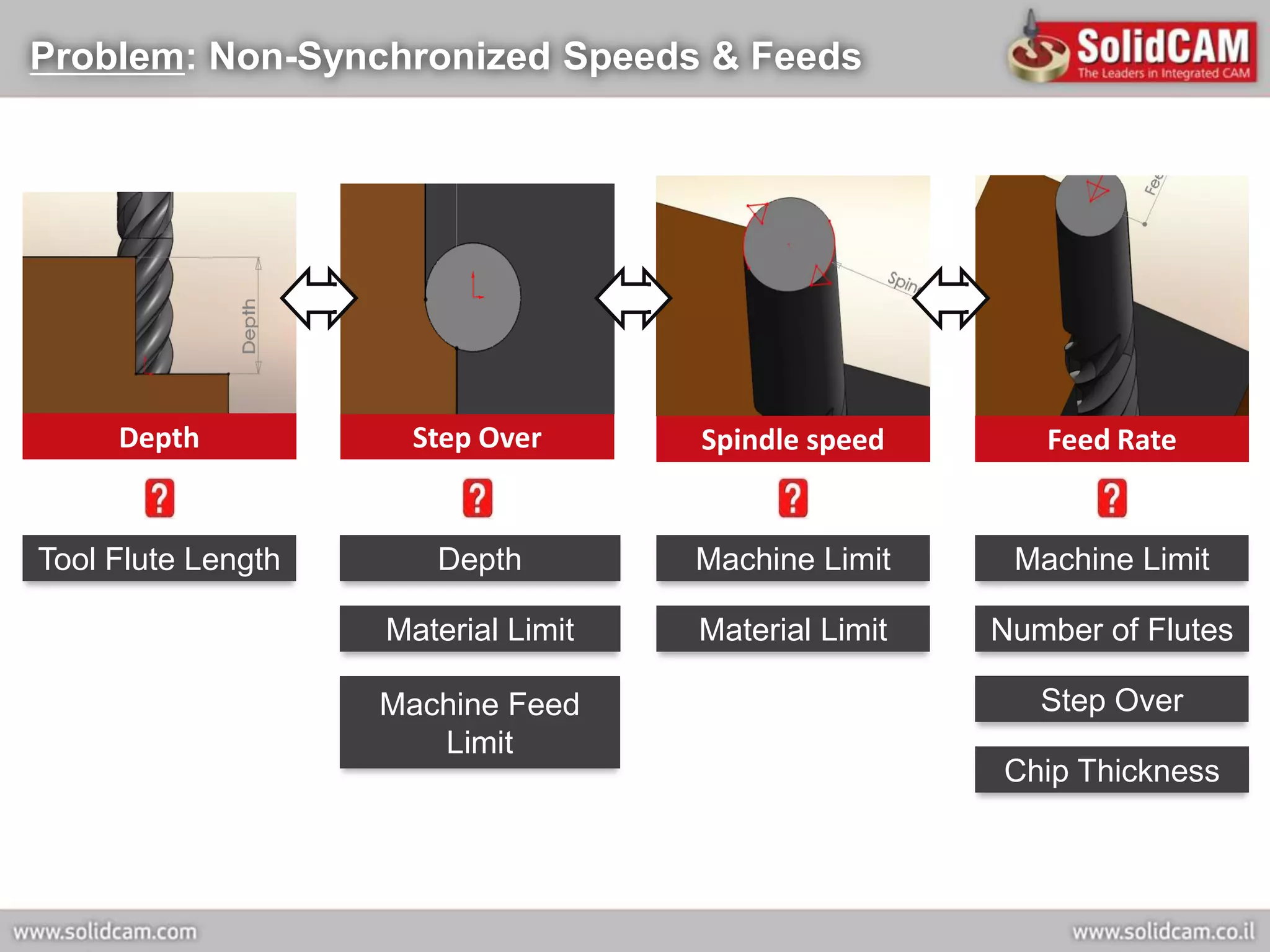

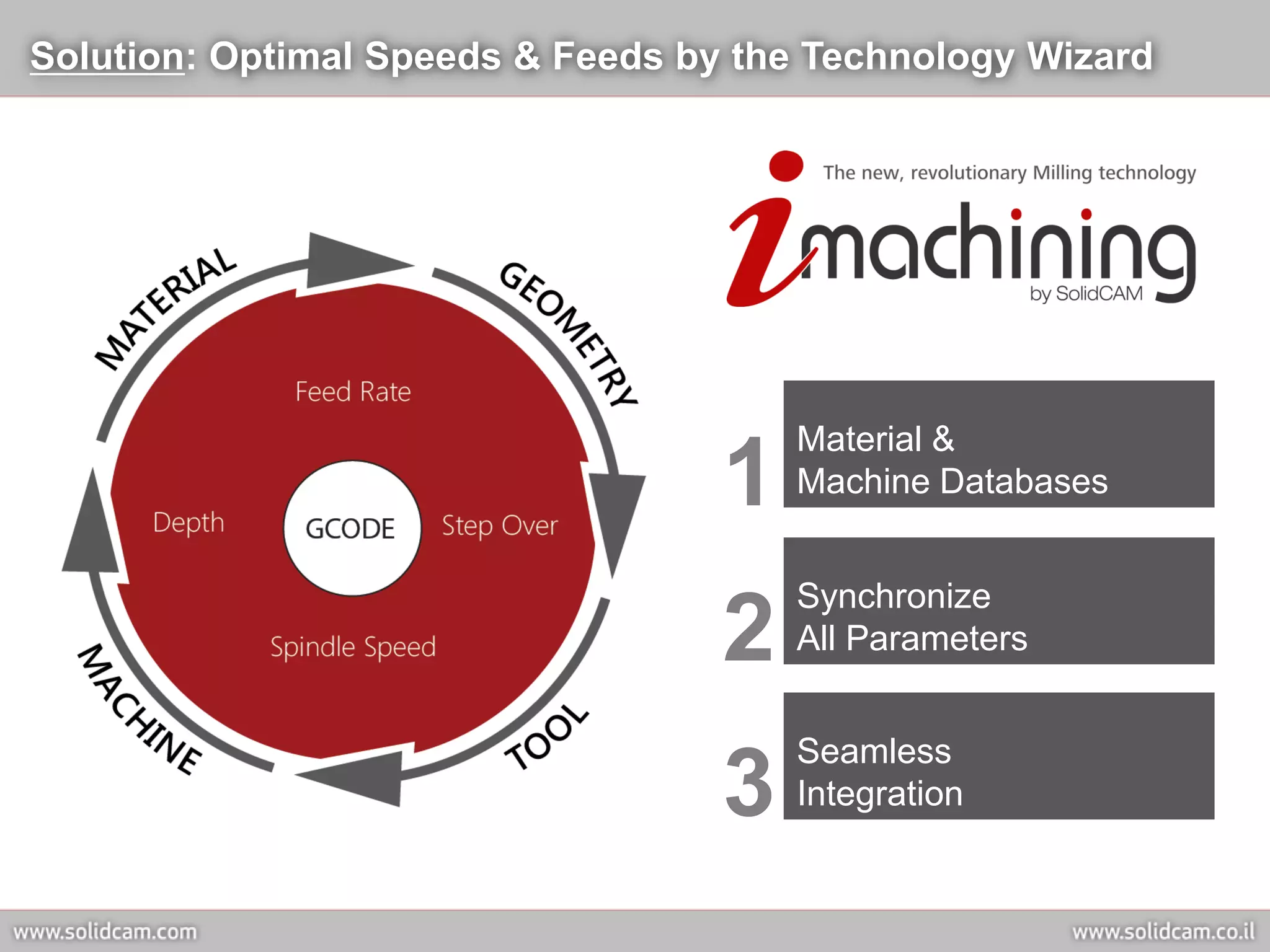

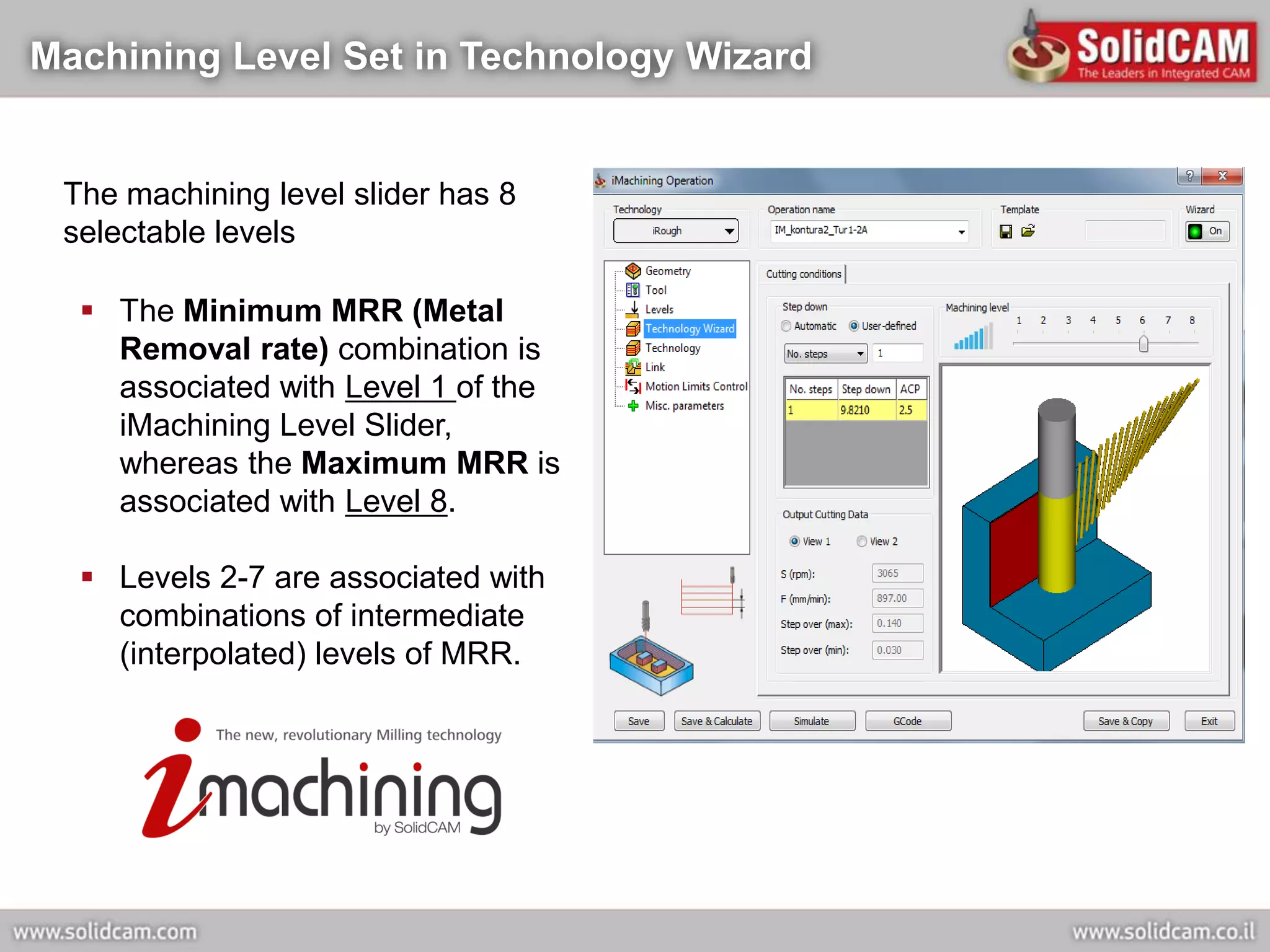

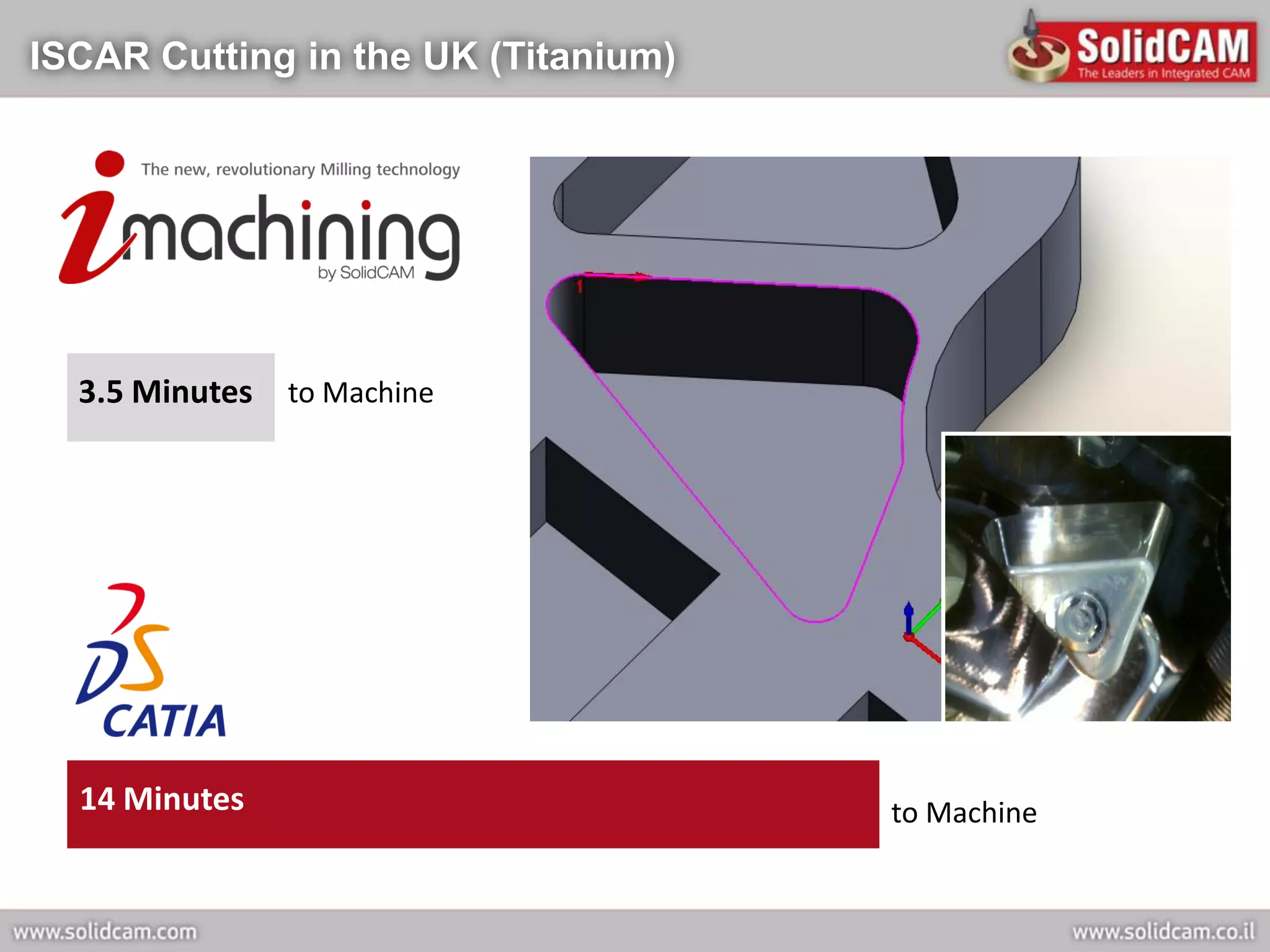

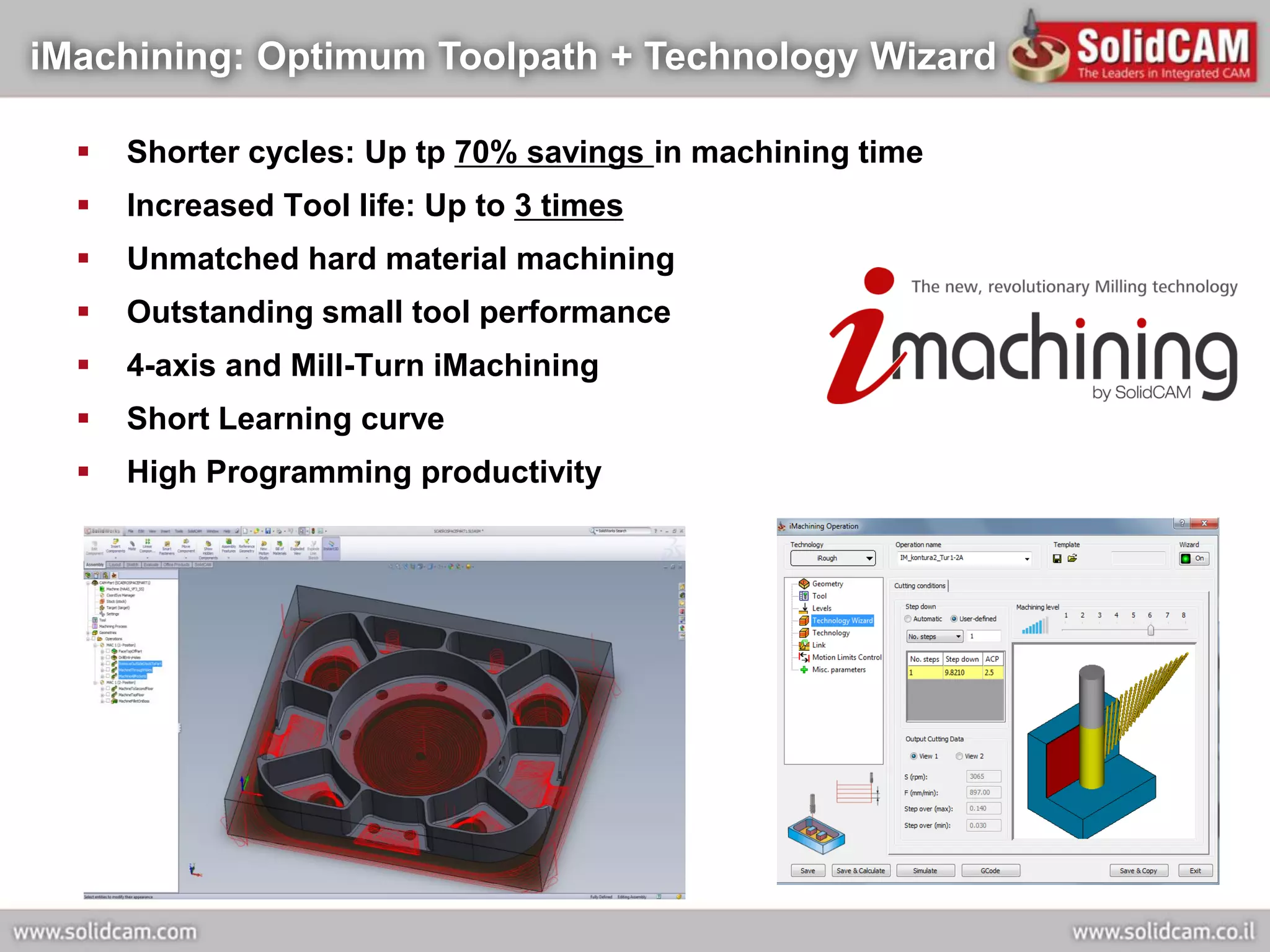

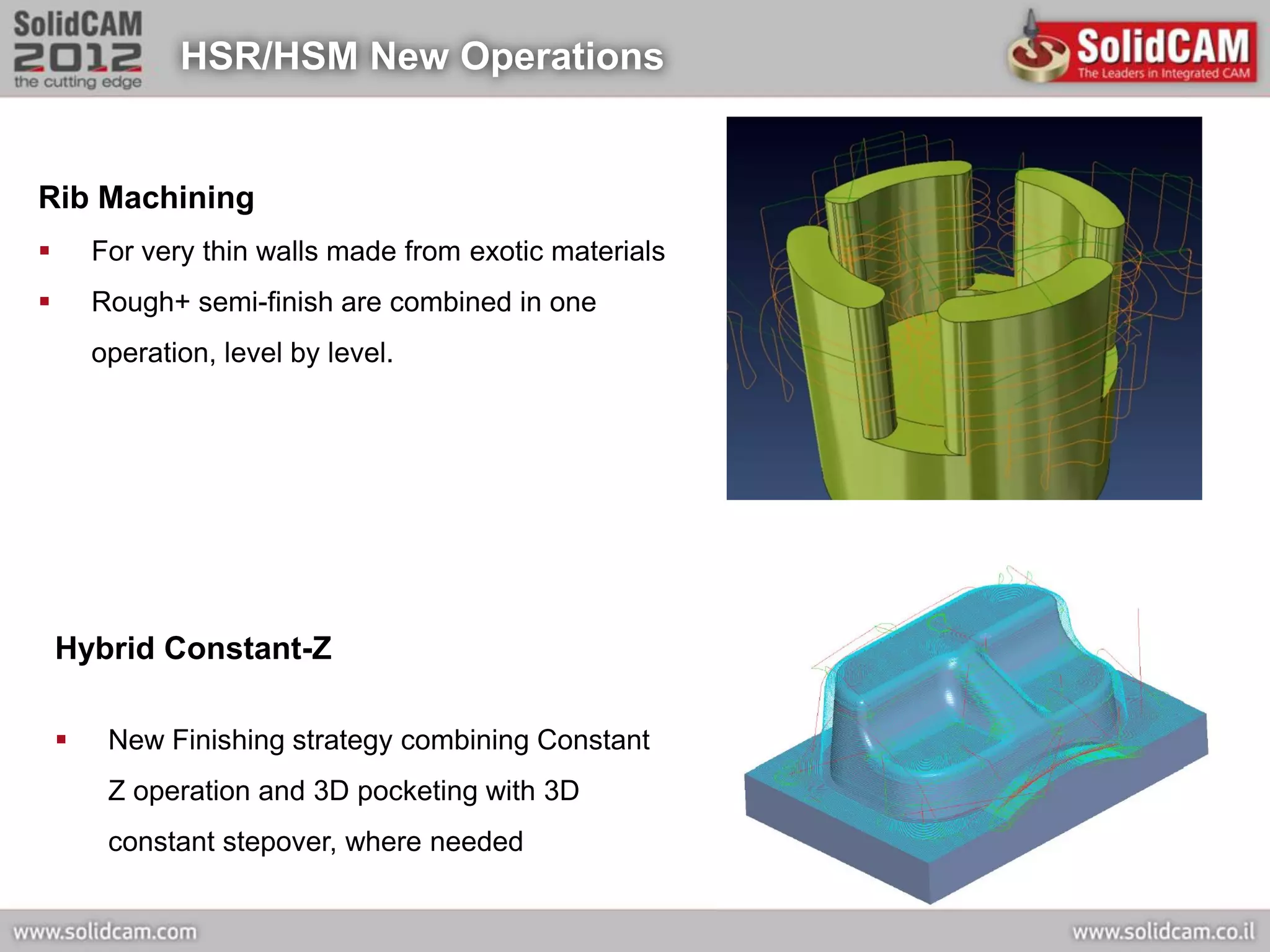

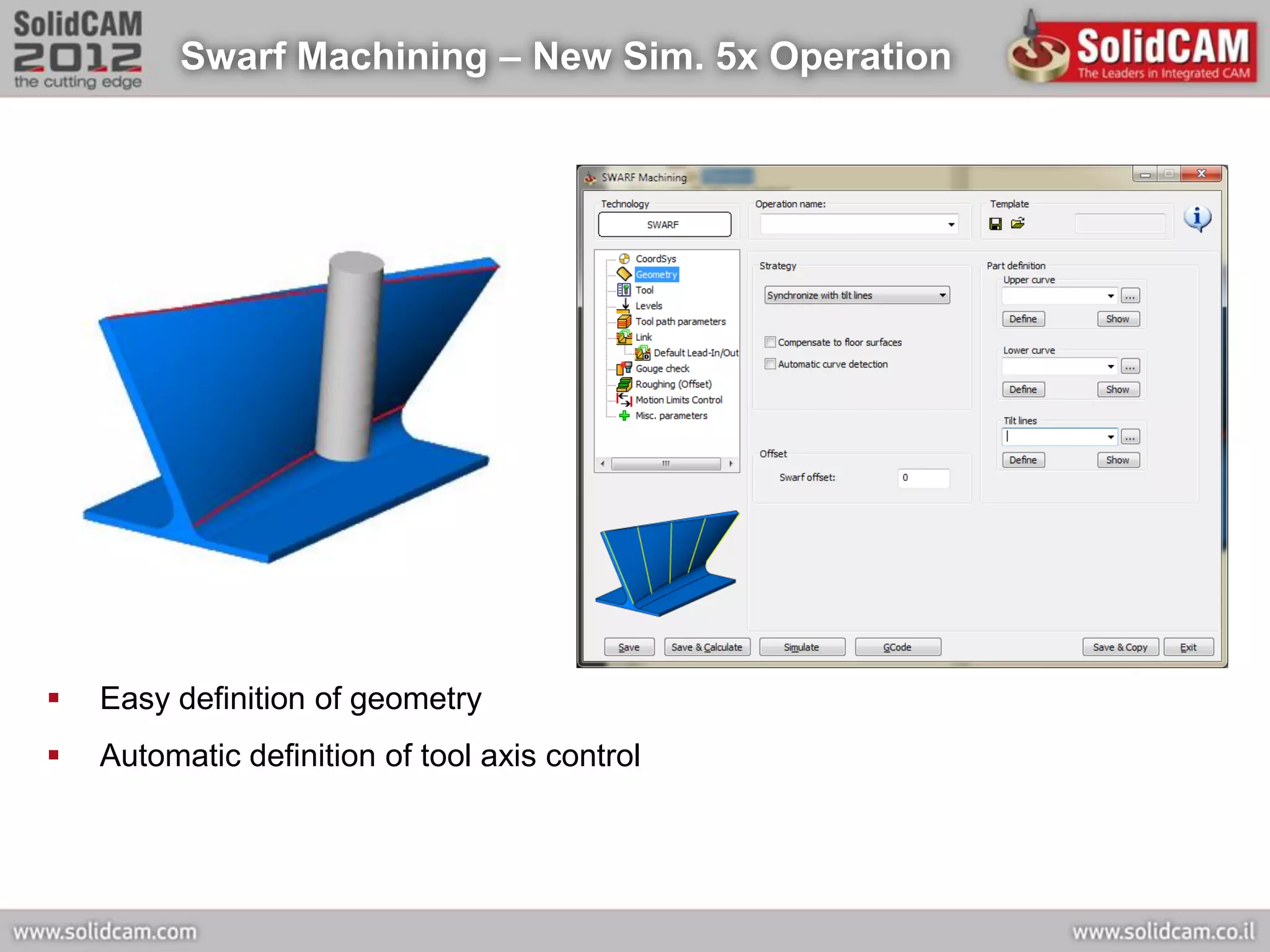

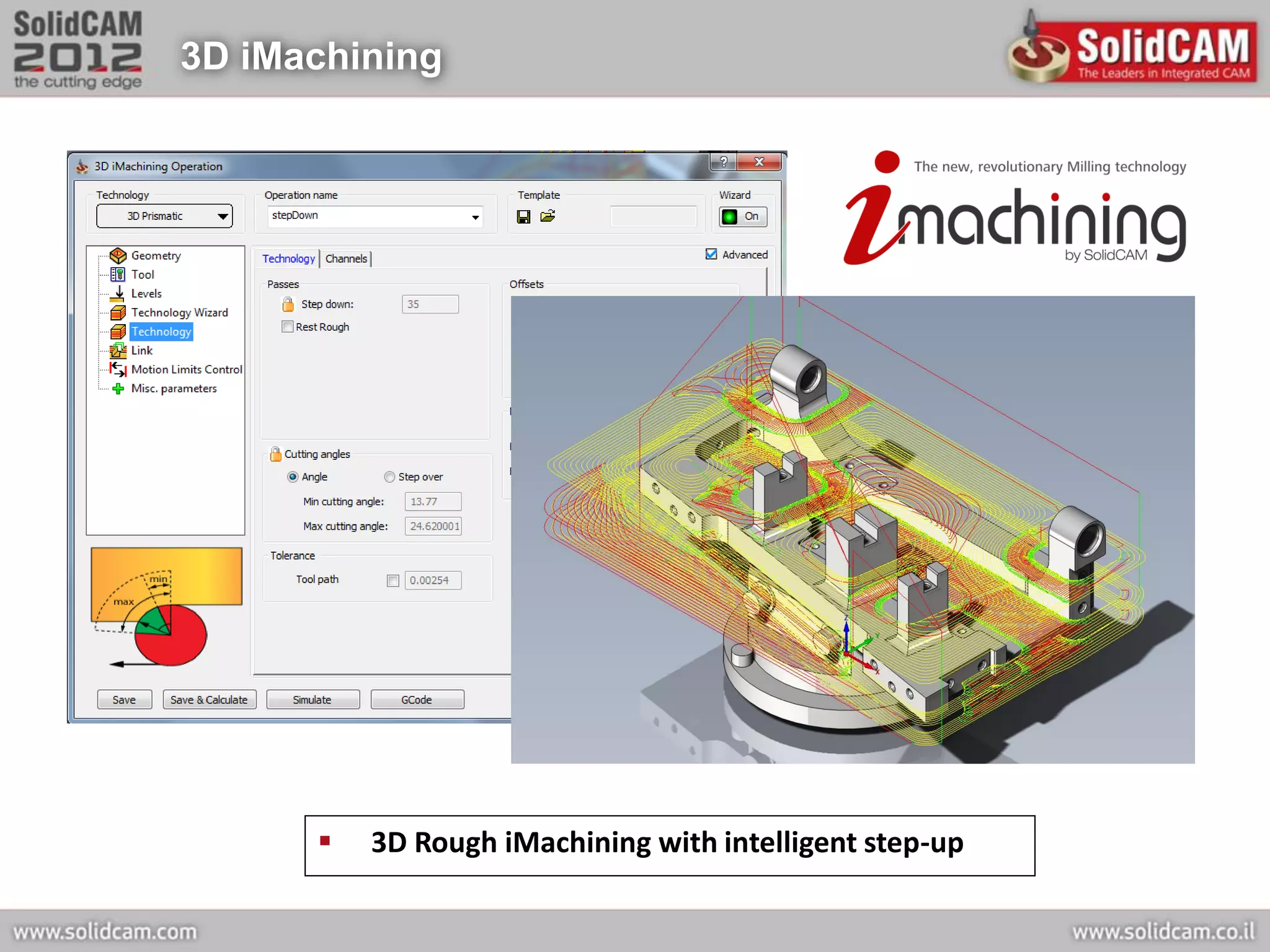

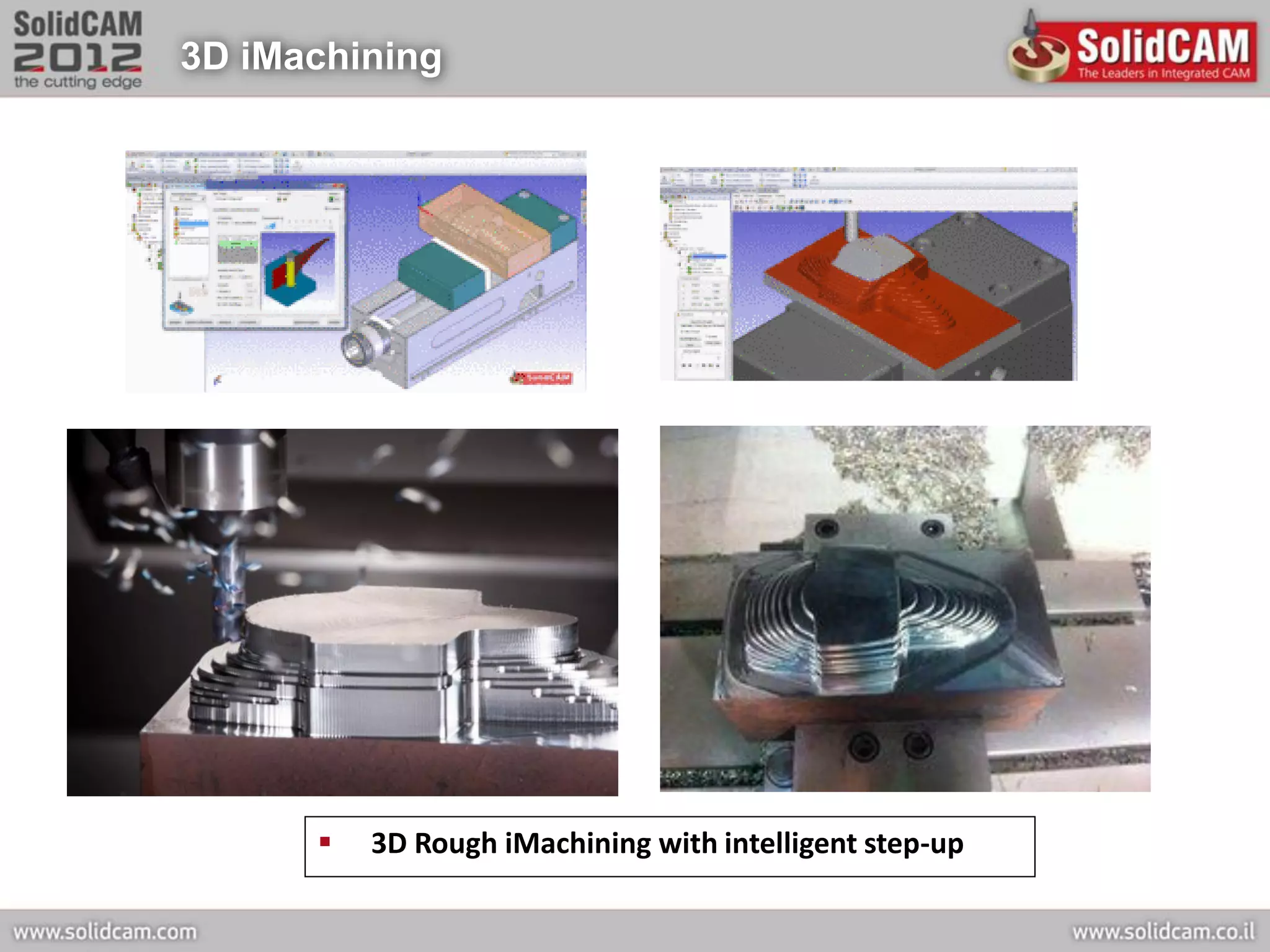

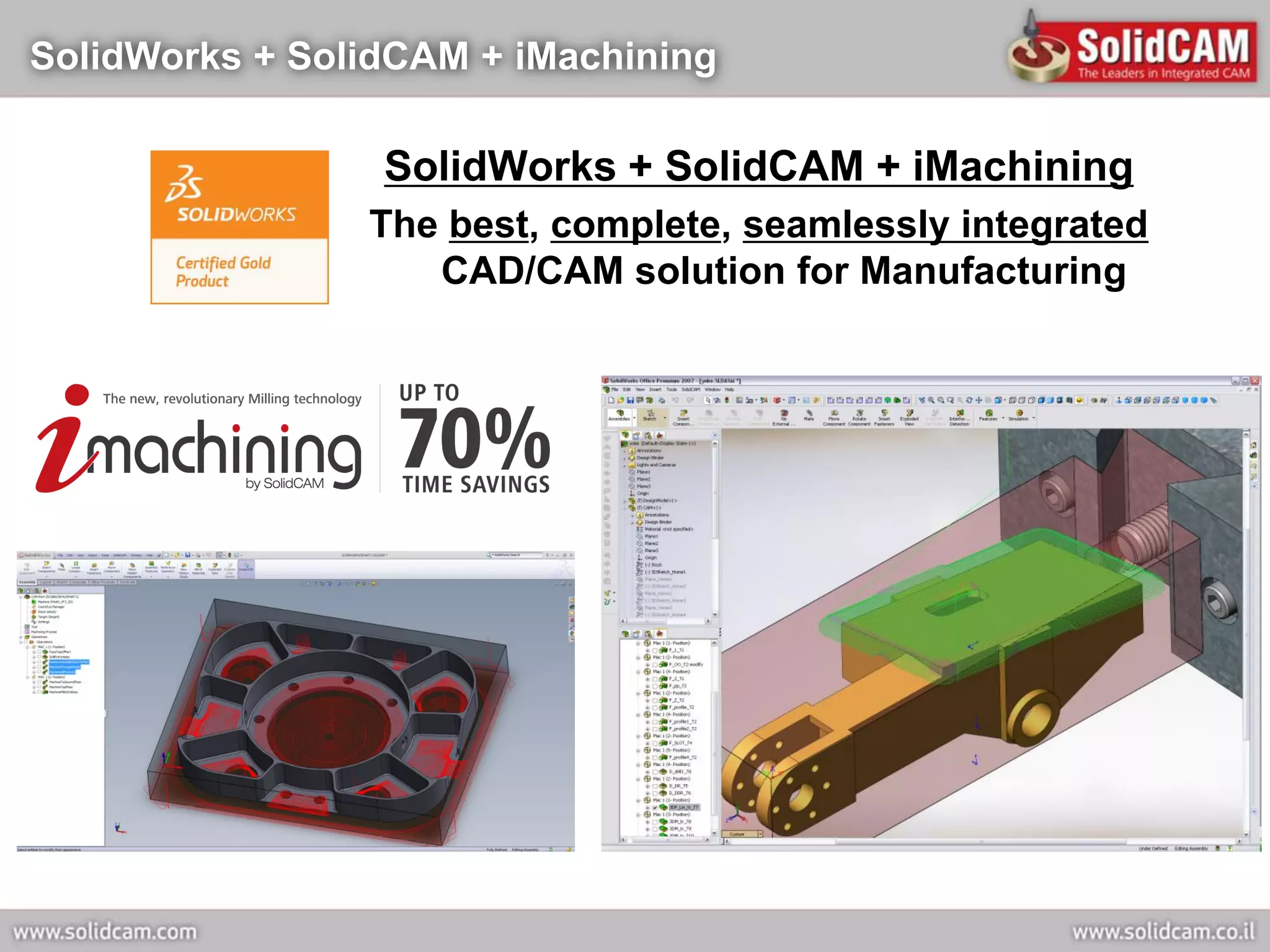

This document provides information about SolidCAM, a CAM software company. It was founded in 1984 and has over 16,500 seats installed worldwide. SolidCAM offers fully integrated CAD/CAM solutions for SolidWorks and Autodesk Inventor. Key features include 2.5D, 3D, and 5-axis machining modules as well as turning capabilities. SolidCAM also provides advanced functions like iMachining for optimized toolpaths and a technology wizard for automatic speeds and feeds. SolidCAM aims to provide a complete manufacturing solution with a seamless CAD/CAM integration and high levels of associativity.