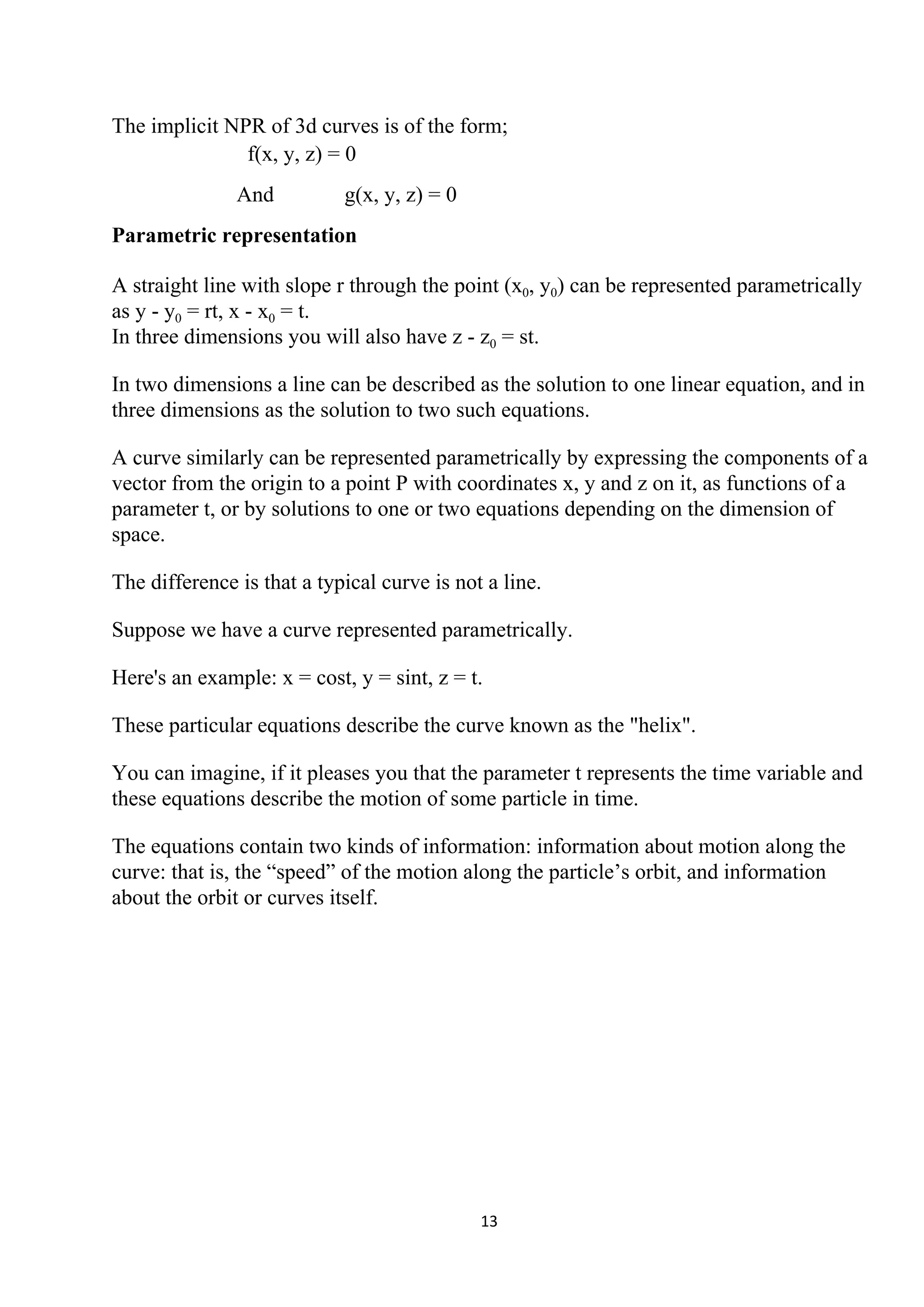

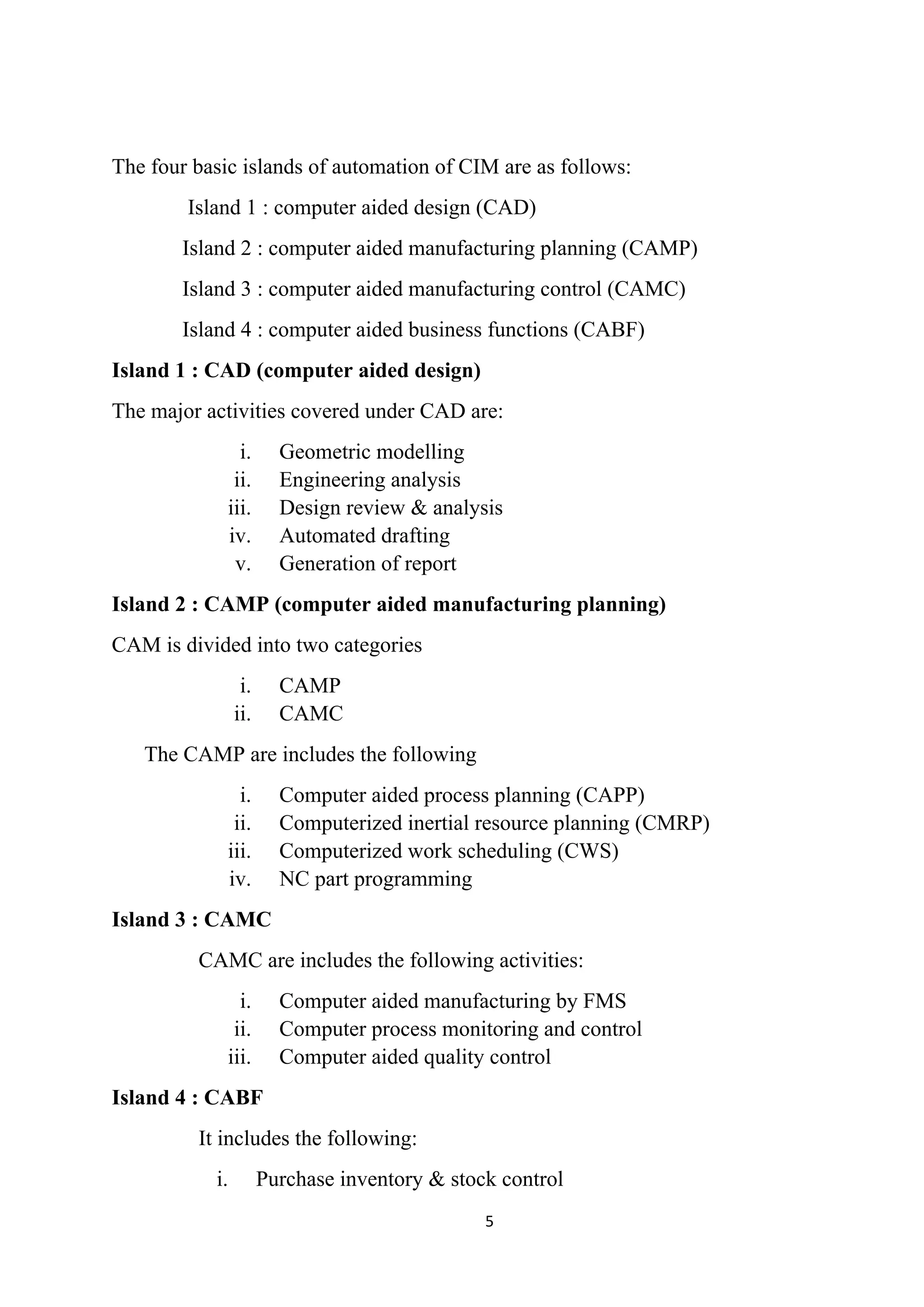

Computer-aided design (CAD) involves using computer systems to assist in the creation, modification, analysis, or optimization of a design. Computer-aided manufacturing (CAM) provides computer support for manufacturing a given product. CAD/CAM integrates design and manufacturing, which were traditionally separate functions, and will ultimately provide the technology base for computer-integrated factories of the future. CAD/CAM software is used to both design and manufacture products through processes like computer numerical control (CNC) machining. Geometric modeling, a key part of CAD/CAM, mathematically describes shapes using methods like wireframe, surface, and solid modeling.

![All the functions of CAD and CAM can be utilized along with some of the

manufacturing activities such as material handling.

CIM system applies computer and communication technology to completely integrate

and automates the following four functions:

I. Design

II. Manufacturing planning

III. Manufacturing & control

IV. Business functions

NC

CAM

FMS

ROBOTICS

Computer Simulation

Optimization

FEM analysis

Solid modelling

CAD

[Integration of technical & business function in CIM]

4](https://image.slidesharecdn.com/introductiontocad-180929045633/75/Introduction-to-cad-4-2048.jpg)

![Dunn used a different way to define a corner by the distance and angle between two

straight line segments. This is a new way by defining features as a parameterized

composition of several components.

Edges: Edges are one-dimensional structure features of an image. They represent the

boundary of different image regions. The outline of an object can be easily detected by

finding the edge using the technique of edge detection.

Blobs: Blobs represent regions of images, which can be detected using blob

detection method.

Ridges: From a practical viewpoint, a ridge can be thought of as a one-dimensional

curve that represents an axis of symmetry. Ridges detection method-see ridge

detection

Compound features

Geometric composition

Geometric component feature is a combination of several primitive features and it

always consist more than 2 primitive features like edges, corners or blobs. Extracting

geometric feature vector at location x can be computed according to the reference

point, which is shown below:

i i σi dix = x − 1 + − 1 cos os (θi i) in[ c − 1 + Φ sin s (θi i)− 1 + Φ ]

i θi ∆θiθ = − 1 +

Boolean Composition

Boolean compound feature consists of two sub-features which can be primitive

features or compound features. There are two types of Boolean features: conjunctive

feature whose value is the product of two sub-features and disjunctive features whose

value is the maximum of the two sub-features.

Feature space

Feature space was firstly considered in computer vision area by Siegen. He used

multilevel graph to represent the geometric relations of local features.

Learning algorithms

There are many learning algorithms which can be applied to learn to find distinctive

features of objects in an image. Learning can be incremental, meaning that the object

classes can be added at any time.

Geometric feature extraction methods

7](https://image.slidesharecdn.com/introductiontocad-180929045633/75/Introduction-to-cad-7-2048.jpg)

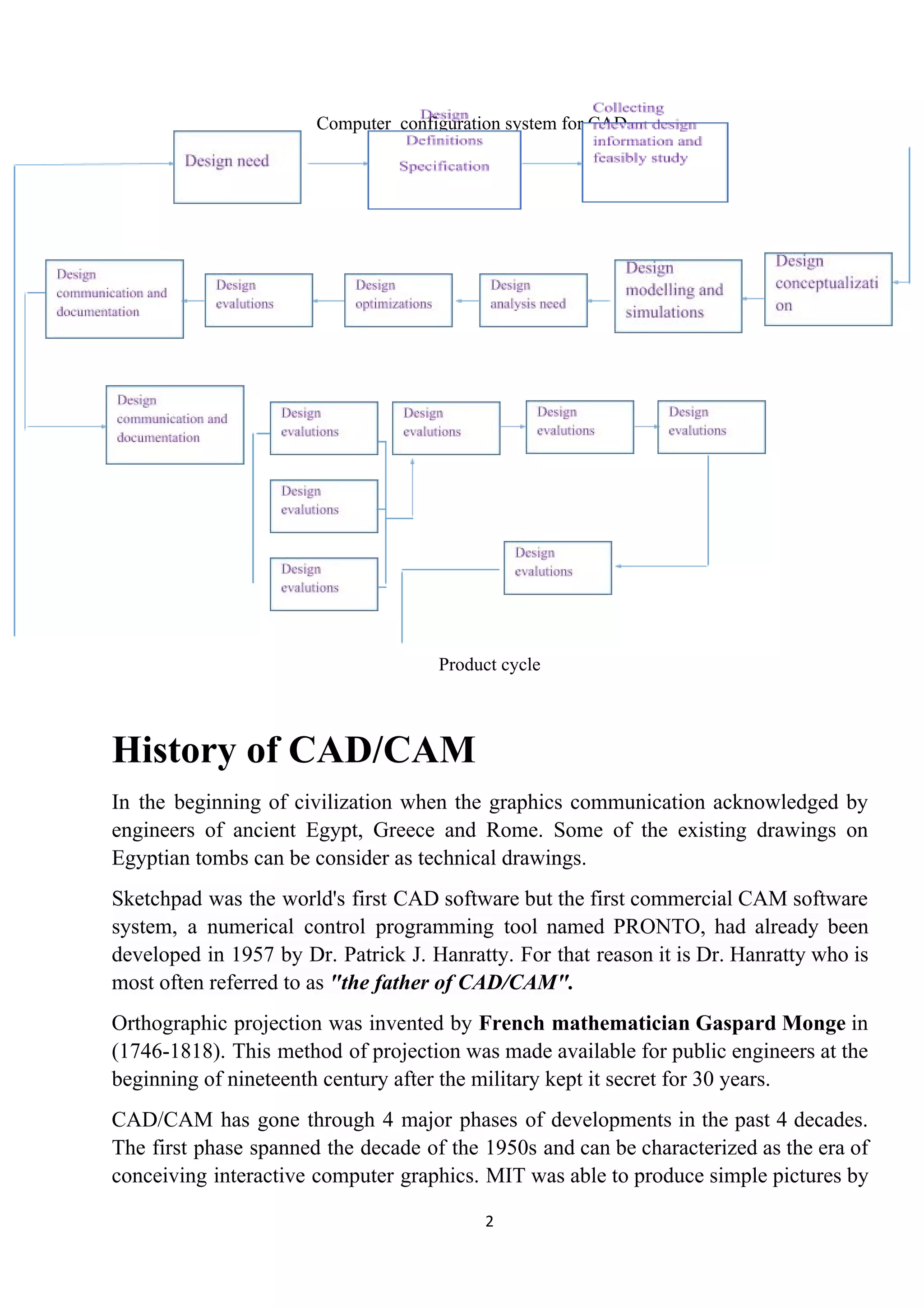

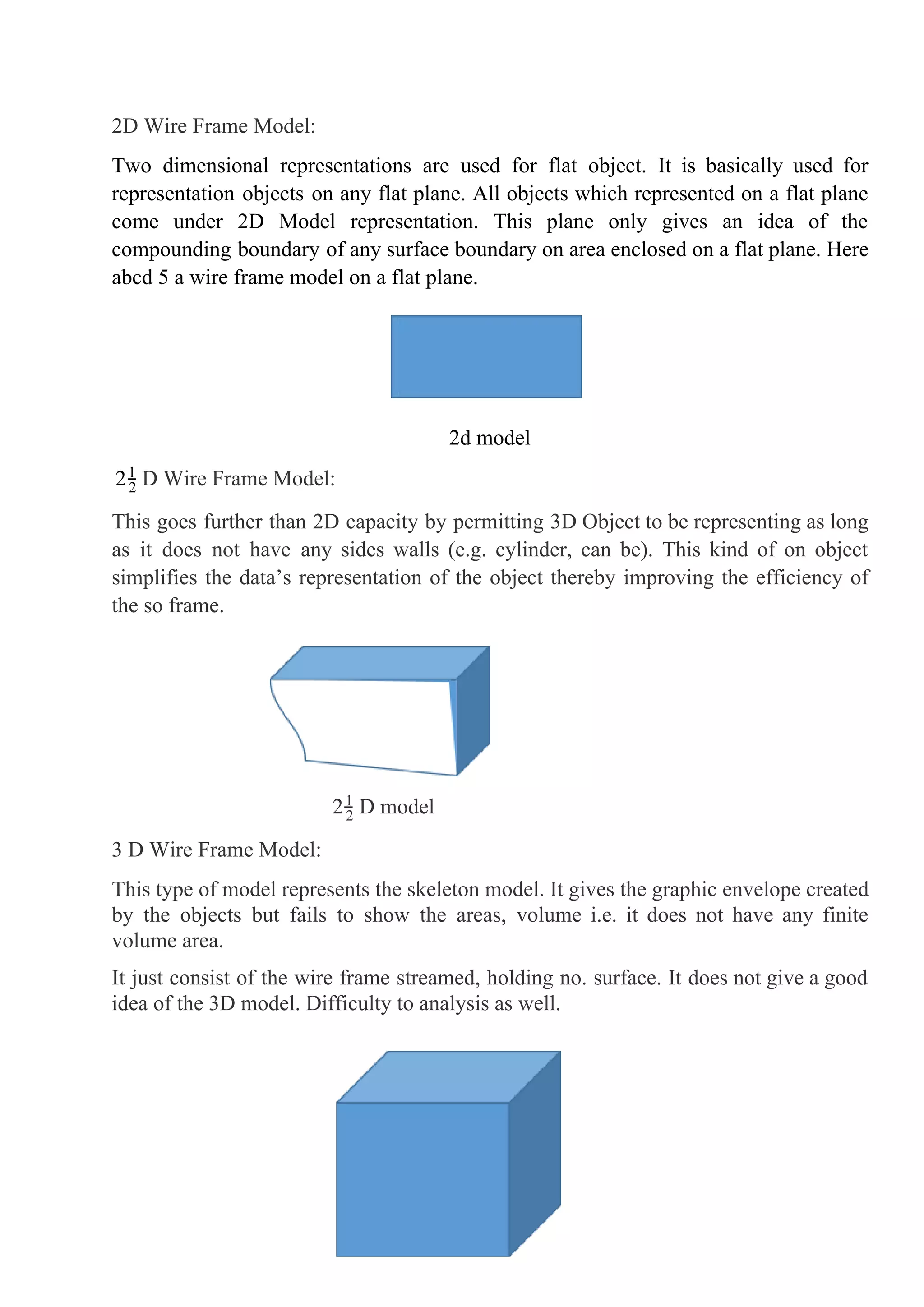

![Explicit, implicit & parametric co-ordinate

system

● Curves can be mathematically represents by two methods

● Non – parametric representation & parametric representation

Non – parametric representation

Explicit implicit

● Non – parametric representation

In this, curve is representation as a relation between x, y and z.

● Explicit non – parametric representation

The explicit NPR of 2d curves in the form : y p(x,y)

P = =x y[ ] x f[ (x) ]

x

P = = ox y[ ]

t

x f[ (x) ]

t

The explicit NPR of 3d curves in the form : y p(x,y,z)

P = =x y z[ ] x f g[ (x) (x) ]

x

P = = zx y z[ ]

t

x f g[ (x) (x) ]

t

● Implicit non – parametric representation

The implicit NPR of 2d curves is of the form;

f(x, y) = 0

12](https://image.slidesharecdn.com/introductiontocad-180929045633/75/Introduction-to-cad-12-2048.jpg)