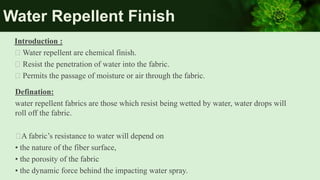

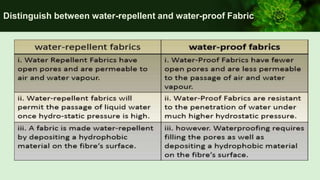

The document introduces the team Phoenix and provides information about water repellent finishes for fabrics. It defines water repellent fabrics as those that resist being wetted by water and allow water drops to roll off. There are three main types of water repellent finishes - non-durable, semi-durable, and durable. Various chemistries are used in each type of finish. Common test methods for evaluating water repellency include the spray test method. Water repellent fabrics have applications in items like umbrellas, swimsuits, car seats, and more.