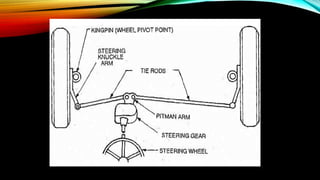

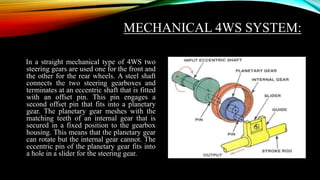

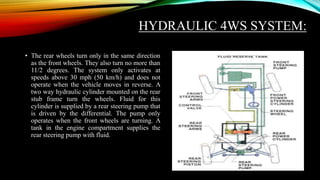

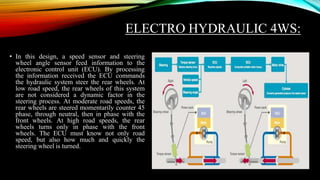

This document discusses a 4 wheel steering system. It provides an introduction and overview of the system, describing the different types including mechanical, hydraulic, and electro-hydraulic systems. It explains the working principles, functions, advantages, and applications of 4 wheel steering. In conclusion, it states that 4 wheel steering provides advantages over 2 wheel steering but the system is also more complex and expensive.