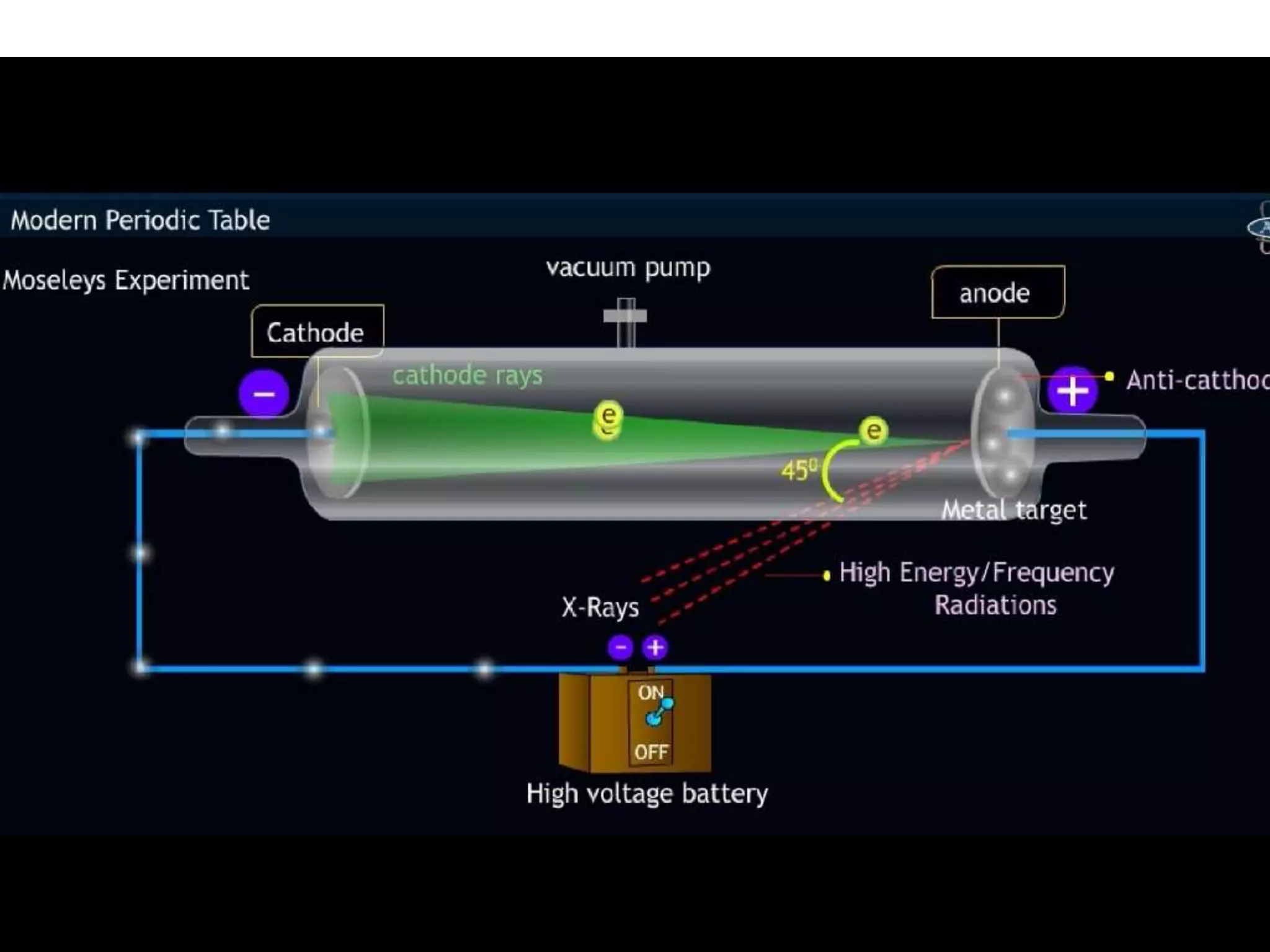

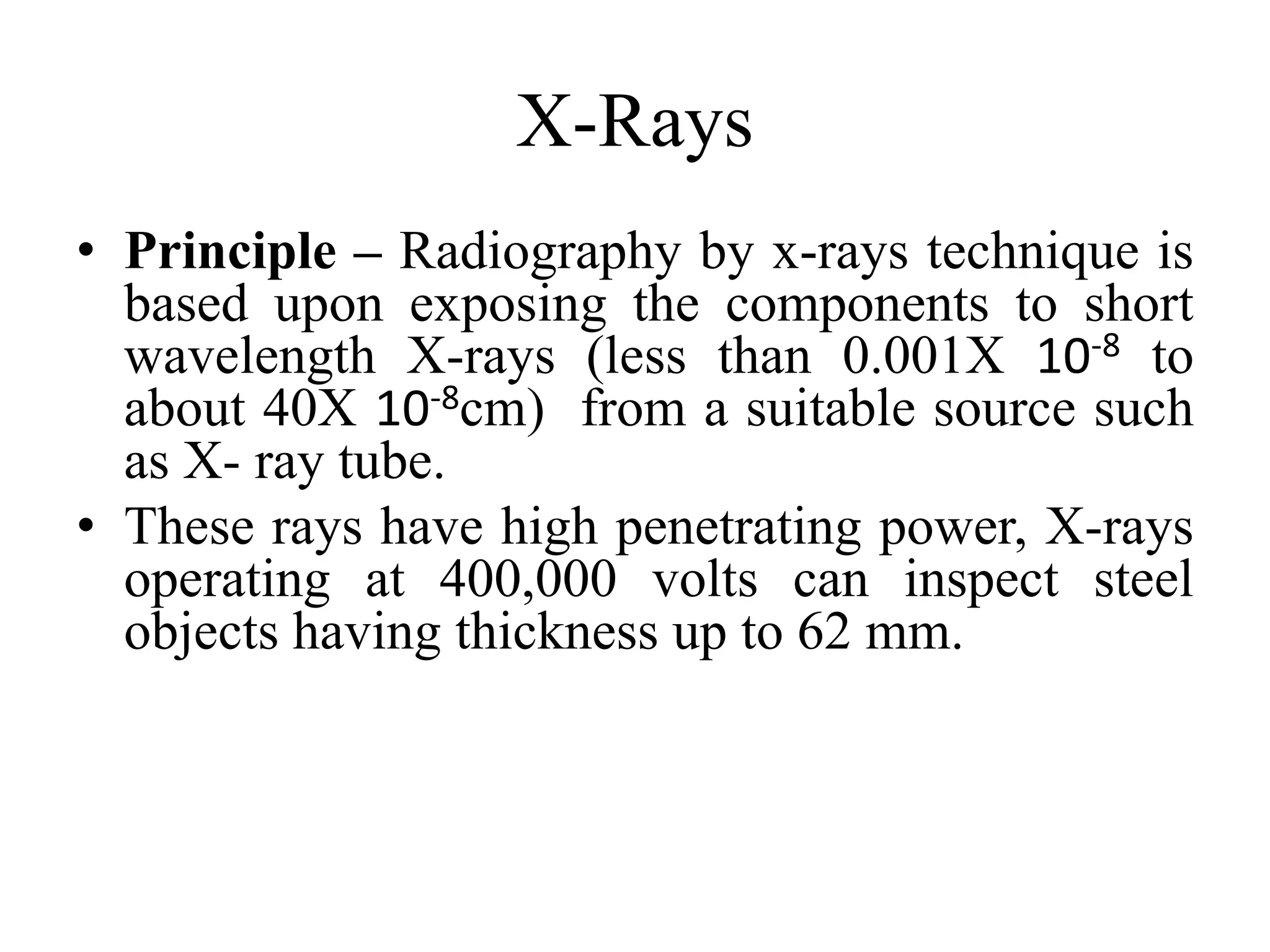

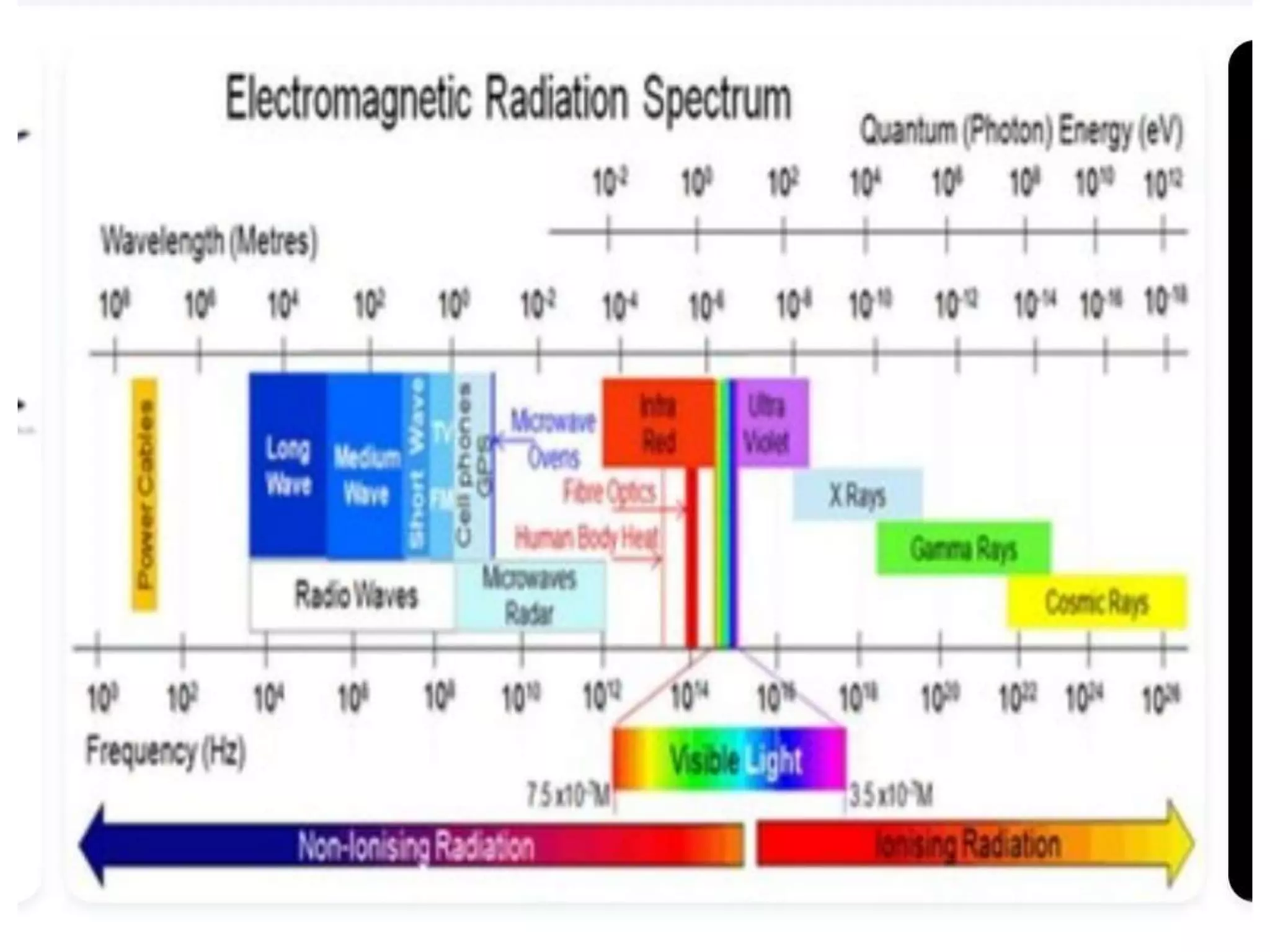

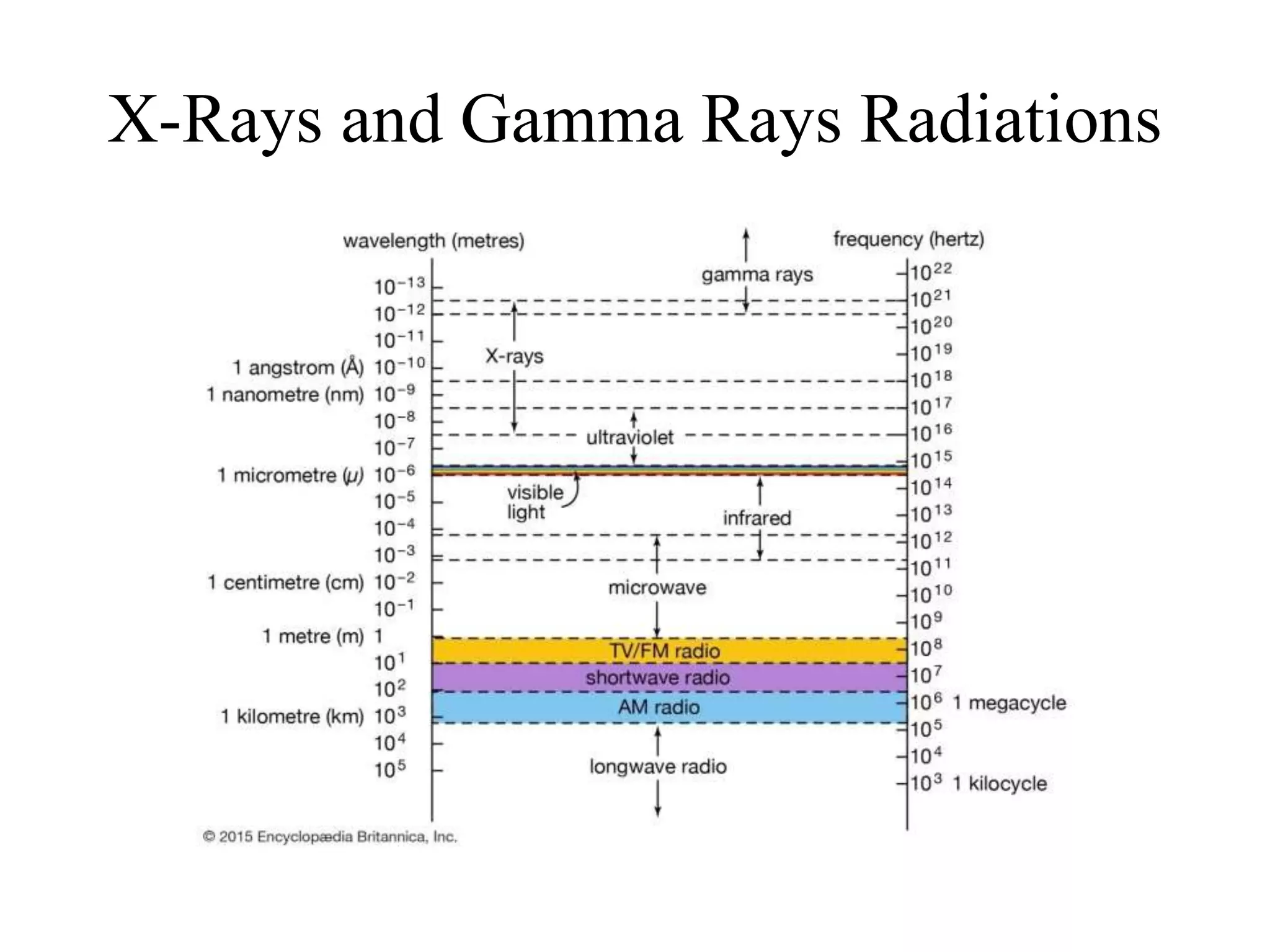

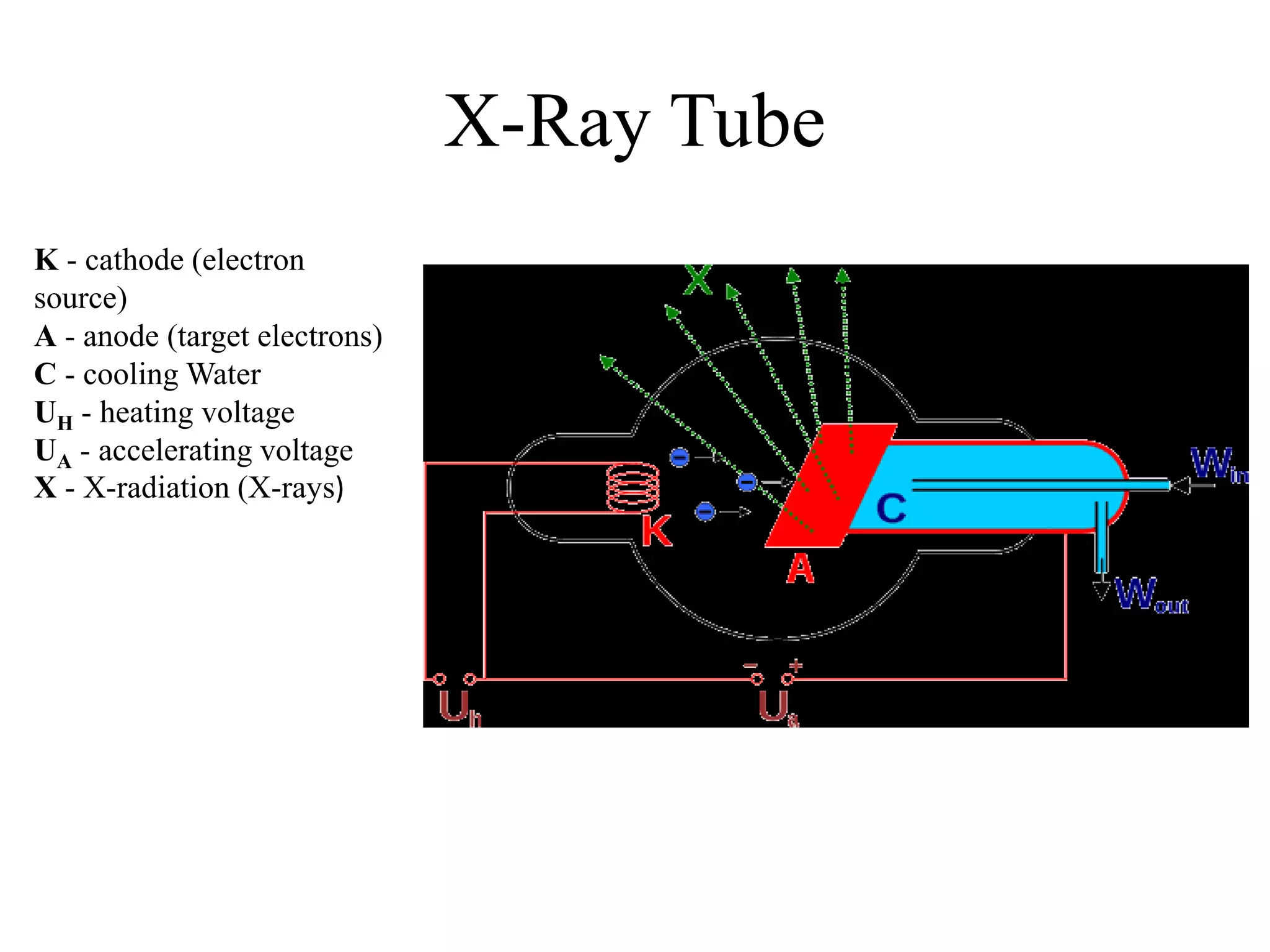

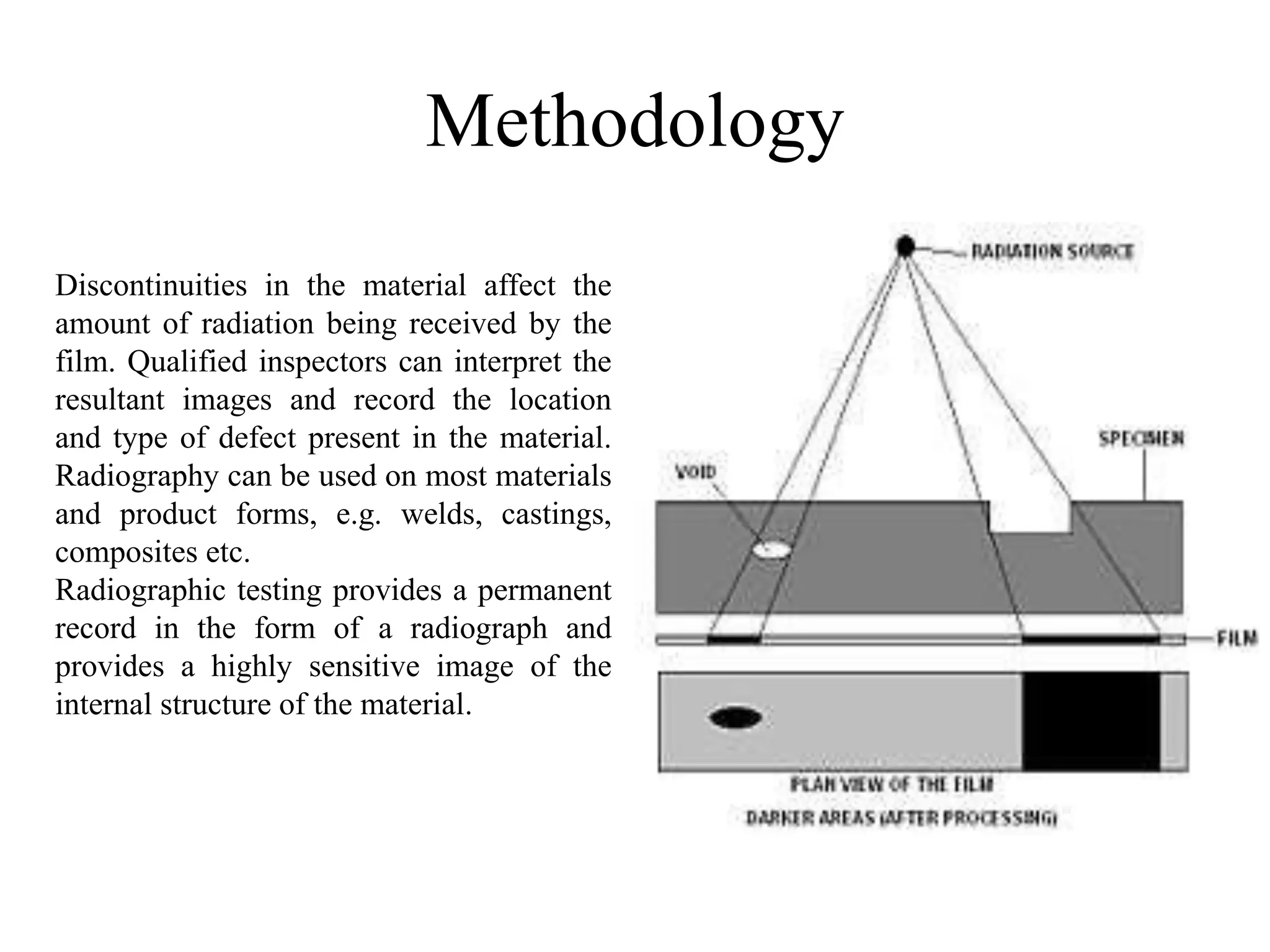

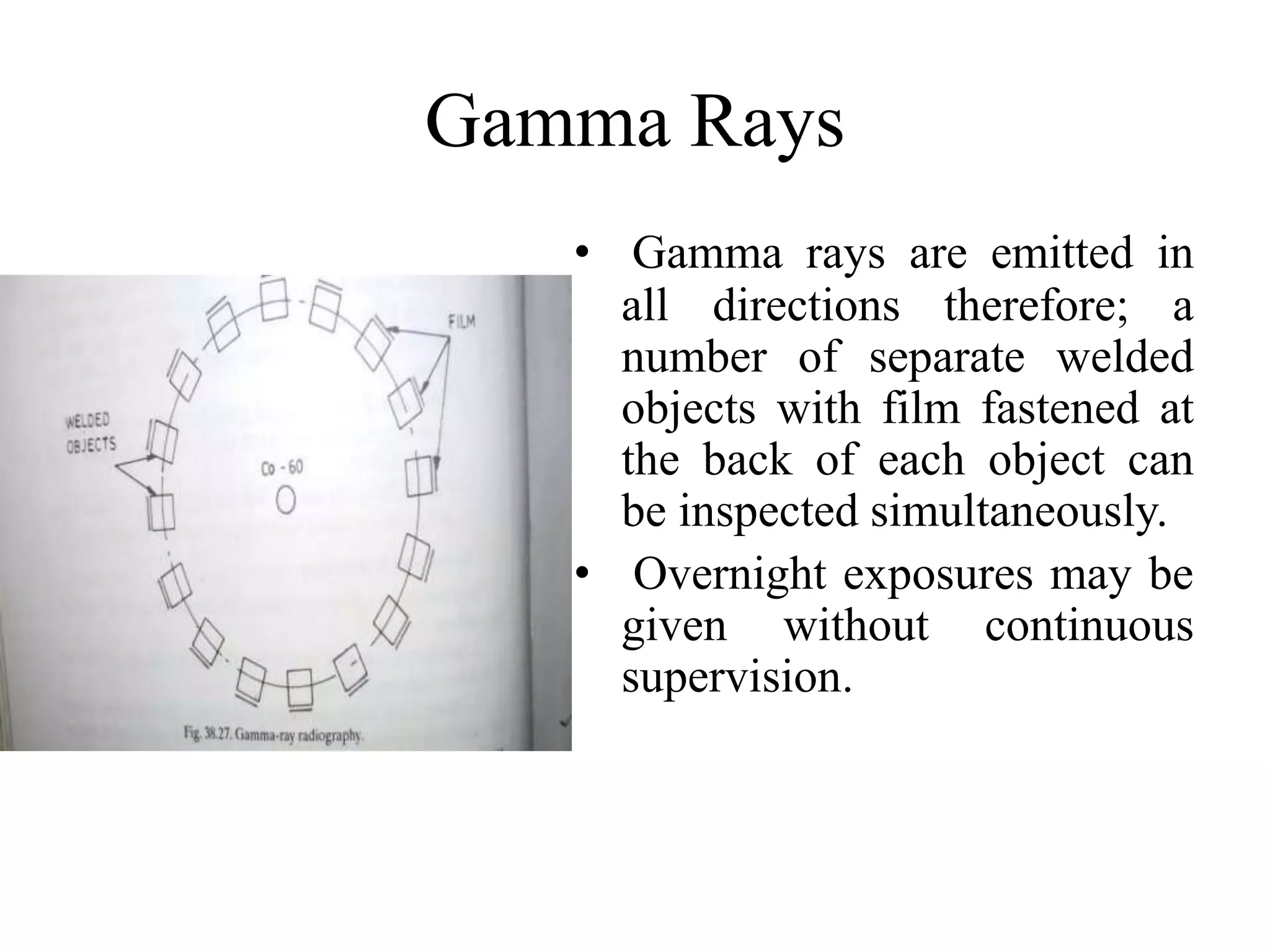

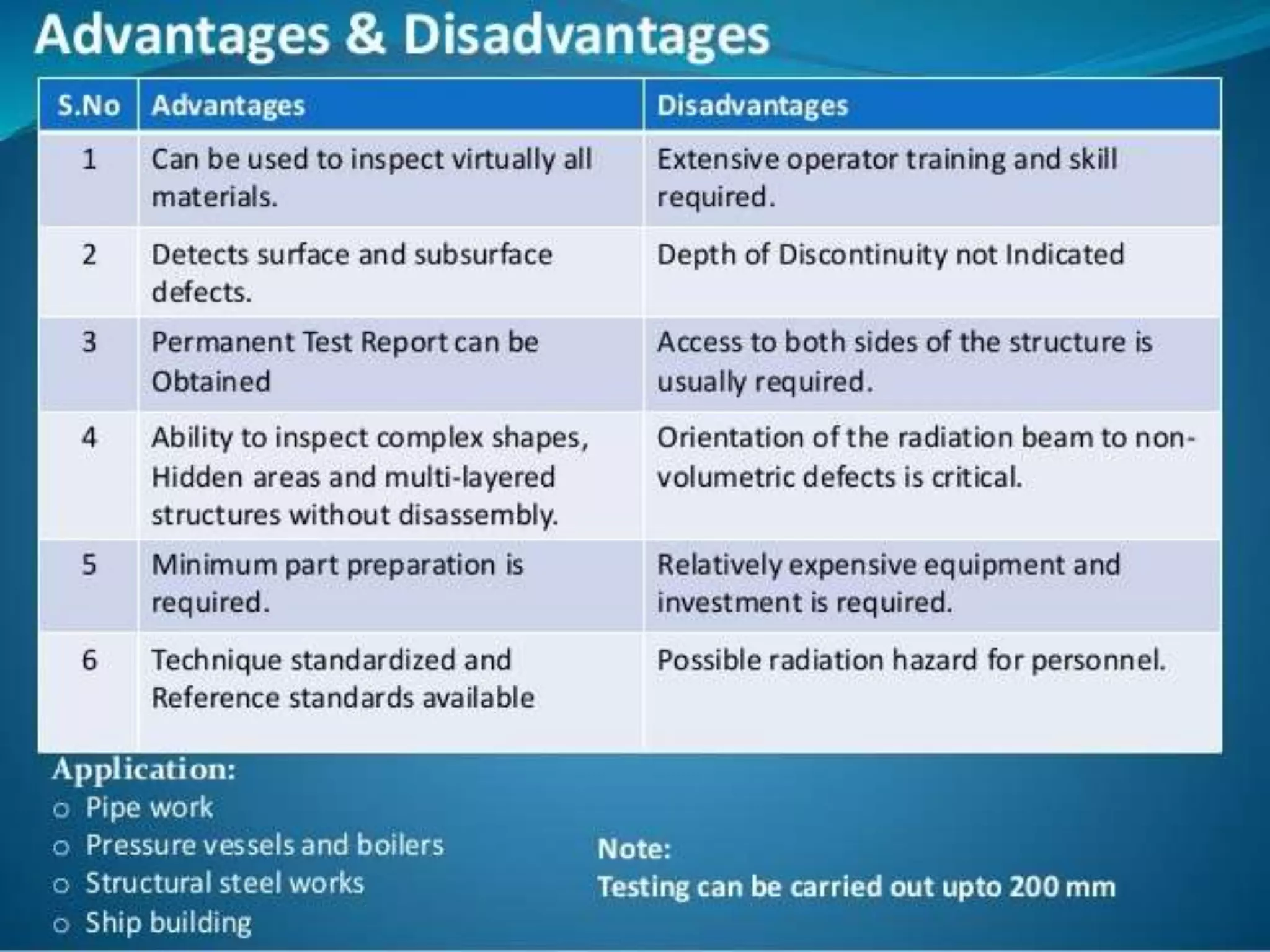

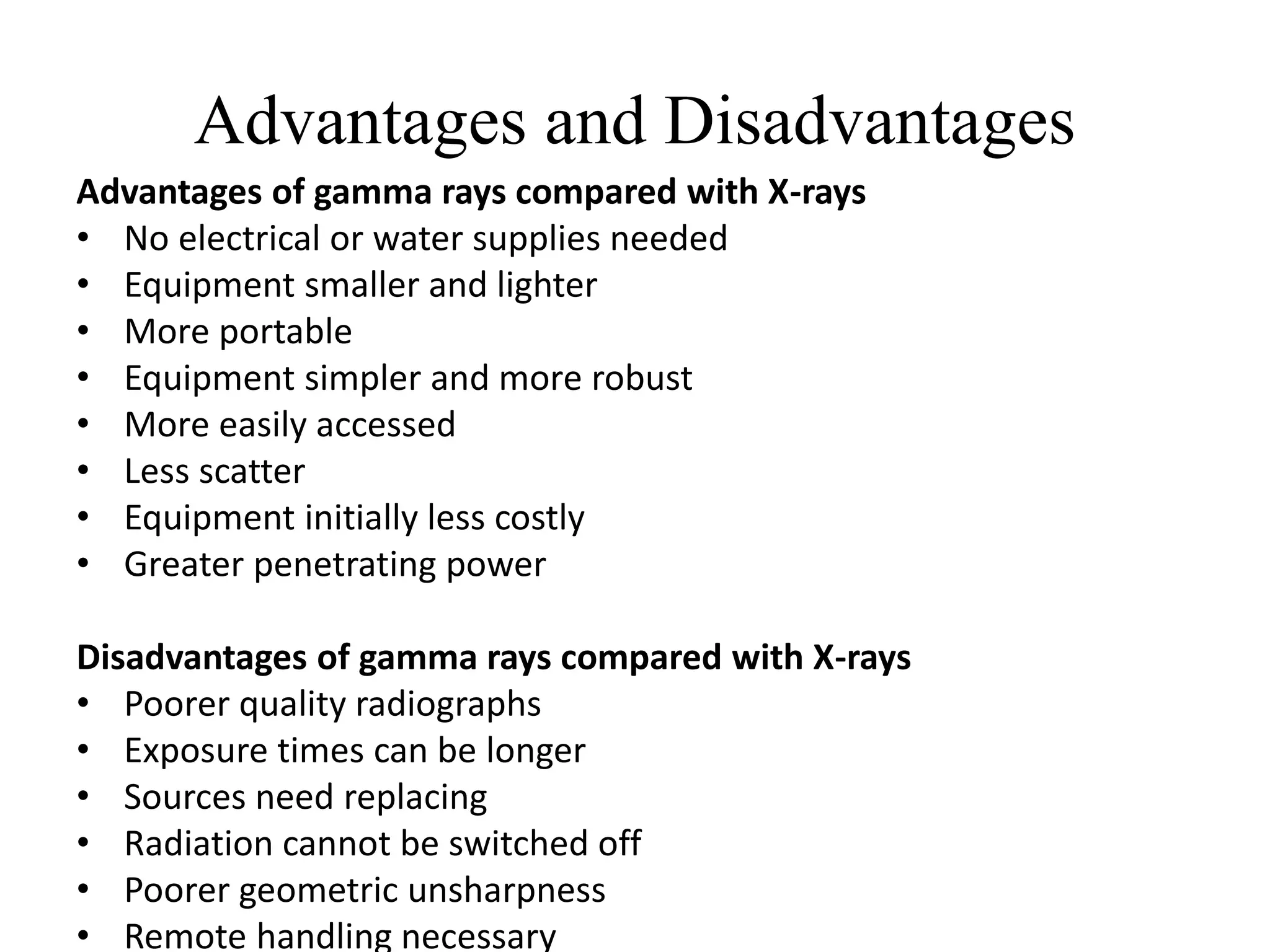

Radiographic testing uses x-rays or gamma rays to detect defects in welds. X-rays are produced when electrons collide with heavy metal targets, while gamma rays come from radioactive sources. The material is exposed to radiation, and defects appear as variations in density on the processed film. Trained inspectors can interpret the film to locate cracks, pores, inclusions and other issues. While gamma rays have advantages like portability, x-rays generally provide higher quality images for precise defect analysis of welds. Both techniques provide a permanent radiographic record but require safety precautions due to invisible radiation.