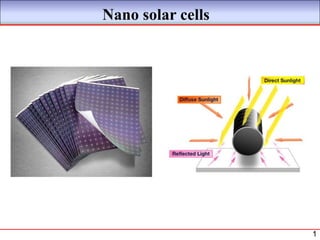

Nano solar cells utilize tiny nanorods or nanoparticles to convert sunlight into electricity in a thin, inexpensive layer. These dye-sensitized or "nano" solar cells consist of a thin layer of nanorods dispersed in a polymer that can be easily mass produced. While efficiency is still low, nano solar cells have potential for low-cost electricity generation due to inexpensive manufacturing using solution-based coating or printing techniques.