This document discusses thin-film photovoltaics research and opportunities. It covers several topics:

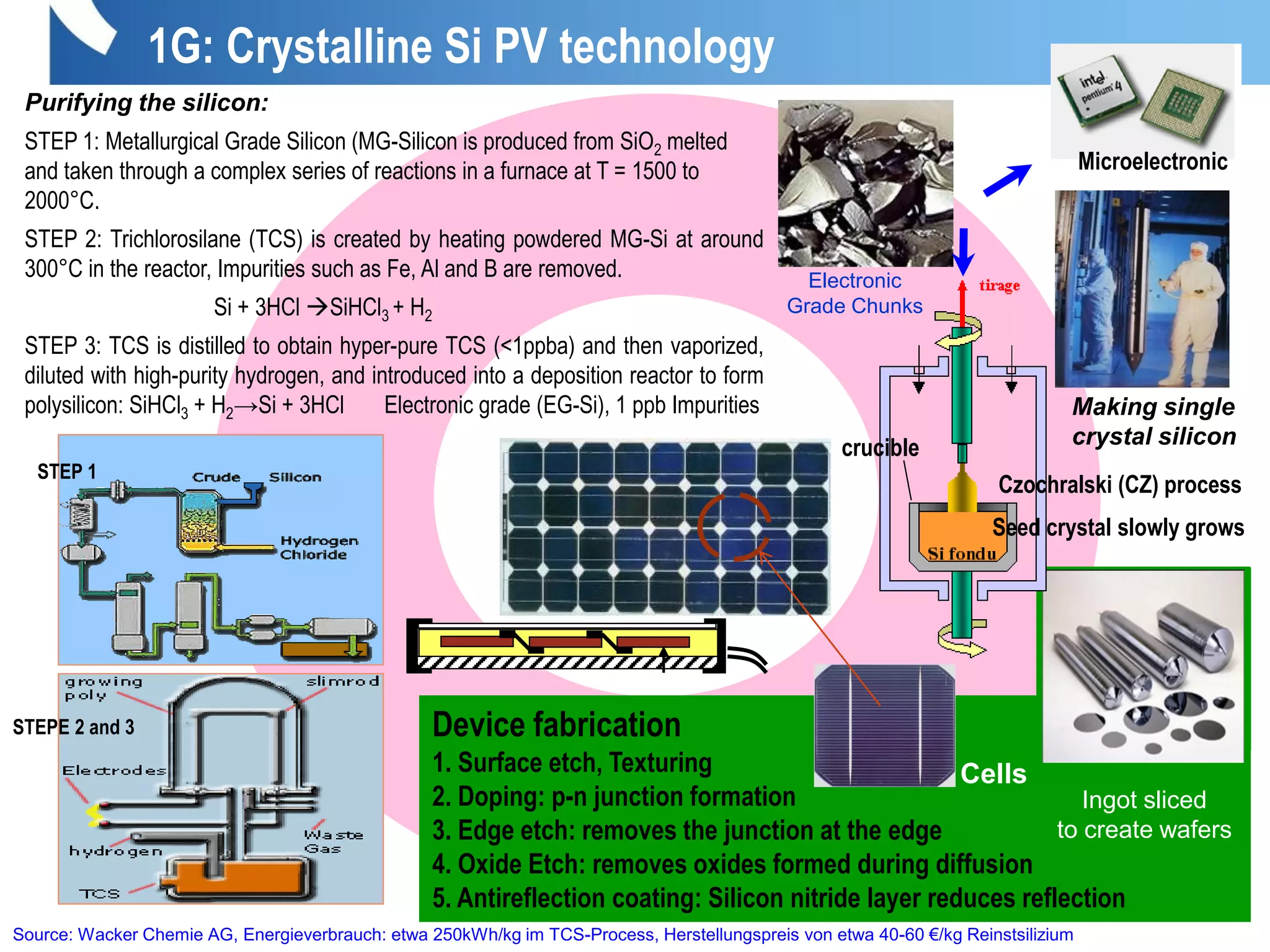

- Thin-film solar cell technologies like CIGS, CdTe, and emerging materials like CZTS have higher efficiencies than earlier generations and lower production costs. Research aims to further improve efficiency and reduce costs.

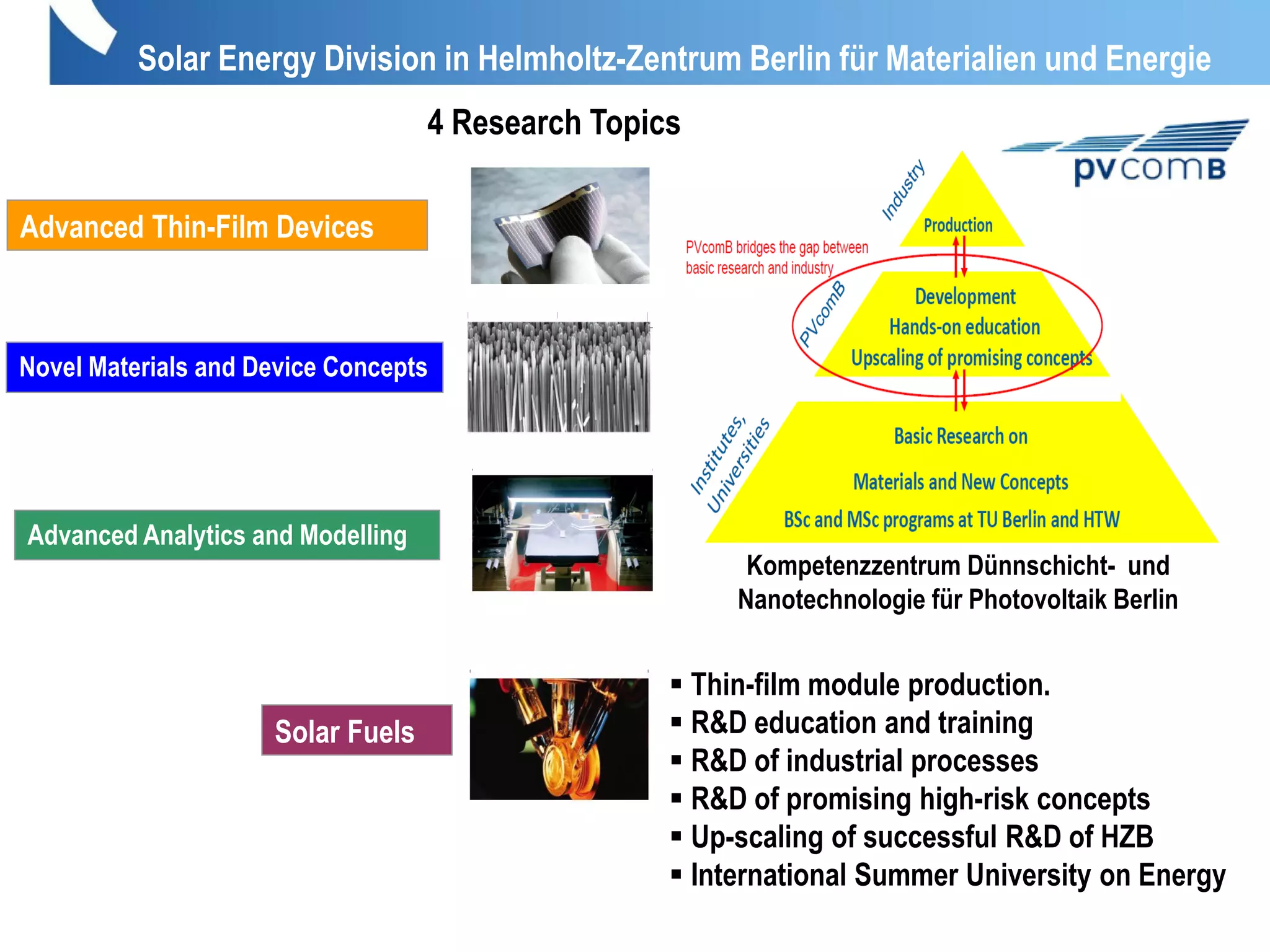

- The Helmholtz-Zentrum in Berlin conducts R&D on thin-film photovoltaics including advanced materials, device concepts, and characterization techniques to develop more efficient and cost-effective solar cells.

- Issues like material scarcity for some thin-film technologies are being addressed through research into alternative materials and processes to produce solar cells on flexible substrates using less raw

![Ahmed Ennaoui / Helmholtz-Zentrum Berlin für Materialien und Energie

Introduction: Key Task of Photovoltaic

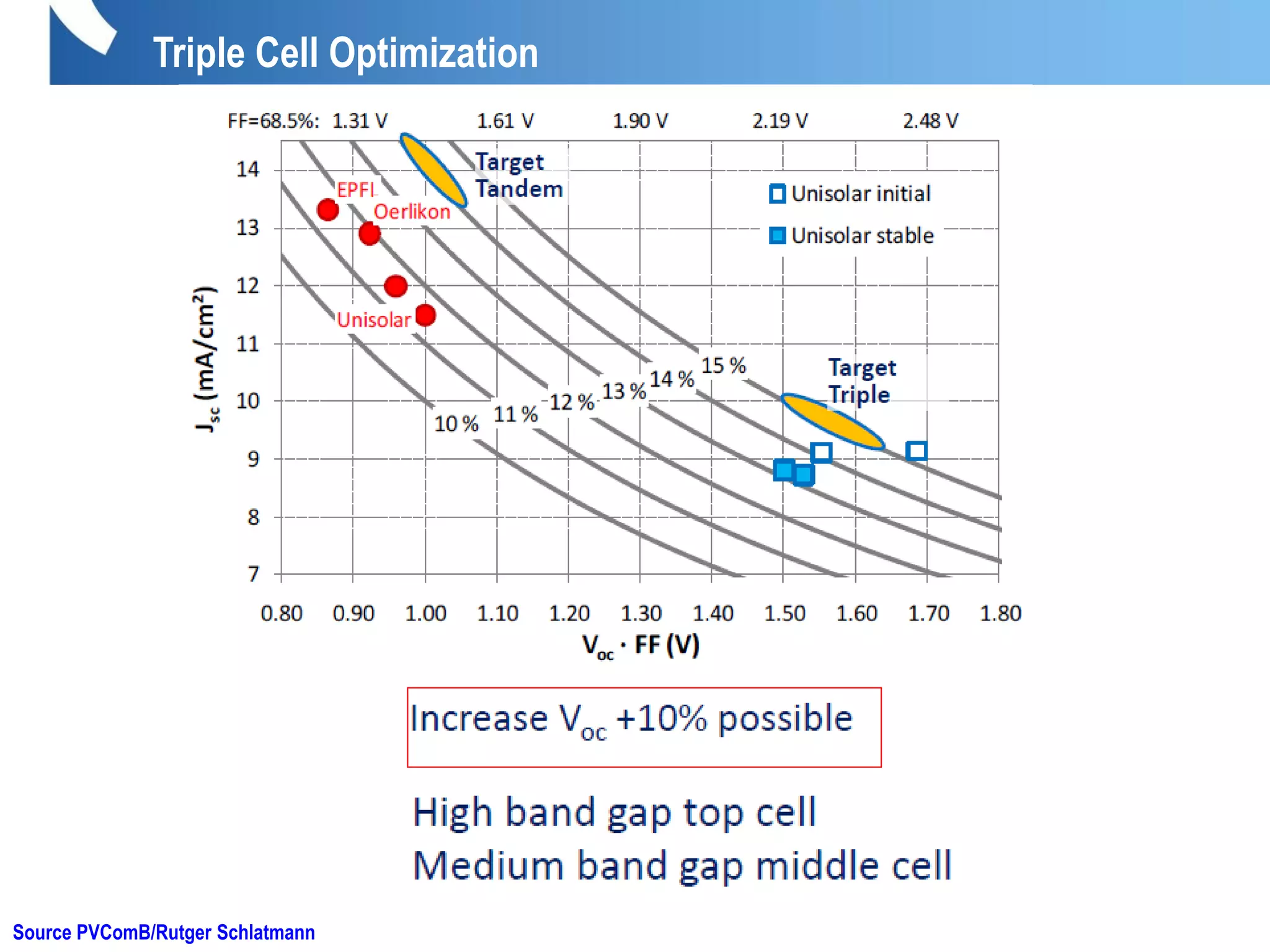

Power [Watt/cm2] = Voltage [Volt ] x Current density [A/cm2]

PV products can be optimized for

location, with lower associated financial

risk based on predictable performance

Key aim is to generate electricity from solar spectrum

EFFECIENCY INCREASING

LESS AREA

LESS MATERIAL

COST FOR PV REDUCED

LOW €/Wp

Materials with small Band gap

But low voltage

Excess energy lost to heat

Generating a large current (JSC)

Materials with large band gap

But low current

Sub-band gap light is lost

Generating a large voltage (VOC)

Two challenges

Solar cell design

versus

solar spectrum

Voltage [Volt ]

JSC[A/cm2]

Power[Watt/cm2]

VOC

0

JSC

maximum

power

point

Jm

Vm

Vm x Jm

AM1,5](https://image.slidesharecdn.com/rdroadmapennaoui-130906055530-/75/Thin-Film-Photovoltaics-R-D-Innovation-Opportunities_Ennaoui-7-2048.jpg)

![Efficiencies beyond the Shockley-Queisser limit

500 1000 1500 2000 2500

0

200

400

600

800

1000

1200

1400

1600

Leistungsdichte[W/m

2

µm]

AM15

GaInP

GaInAs

Ge

Wellenlänge [nm]

(1) Lattice thermalization loss (> 50%)

(2) Transparency to h < Band gap

(3) Recombination Loss

(4) Current flow

(5) Contact voltage loss

Not all the energy of absorbed photon

can be captured for productive use.

(Th. Maxi efficiency ~32% ).

source

1.7 eV

1.1 eV

0.7 eV

R.R. King; Spectrolab Inc., AVS 54th International Symposium, Seattle 2007

Optimistic calculation

Best commercially available cells 37% efficient at 25°C.

75% efficient 0.30 × 0.75 × 850 ≈ 200 W/m2 of electrical power.

At $200/m2 the capital cost would be $1.50/W.](https://image.slidesharecdn.com/rdroadmapennaoui-130906055530-/75/Thin-Film-Photovoltaics-R-D-Innovation-Opportunities_Ennaoui-8-2048.jpg)

![Design to high efficiency solar cells

Light trapping

Reflection Loss: ARC

Material

Parameter

absorption

Important cost factor

thikness

€

αW

p

e

αL1

1

1R)(1η

λ

hc

e

)J(

Φ(λ)

1

N

N

η photons

in

electron

out

Decisive Material

Parameter

The band gap

0.3 0.5 0.7 0.9 1.1

20

0

40

60

80

100

0

1

2

3

4

5

NumberofSunlightPhotons(m-2s-1micron-1)E+19

RExternalQuantumEfficiency,%

c-Si:H junctiona-Si:H junction

AM 1.5 global spectrum

Wavelength, microns

a-Si:H/c-Si:H Cell Spectral Response

Textured TCO

a-Si

Top cell

Back

Reflector

Glass

substrate

Thin film mc-

Si

Bottom cell

GE

λ0λsc dλ.dα-exp.)().ΦR(1.η(λ).qJ

Light from the sun

C10x1.6e

][A.mCurrent

N 19

-2

electron

out

energy[J]photon

][J.mEnergyInput

N

-2

Photon

in ](https://image.slidesharecdn.com/rdroadmapennaoui-130906055530-/75/Thin-Film-Photovoltaics-R-D-Innovation-Opportunities_Ennaoui-19-2048.jpg)