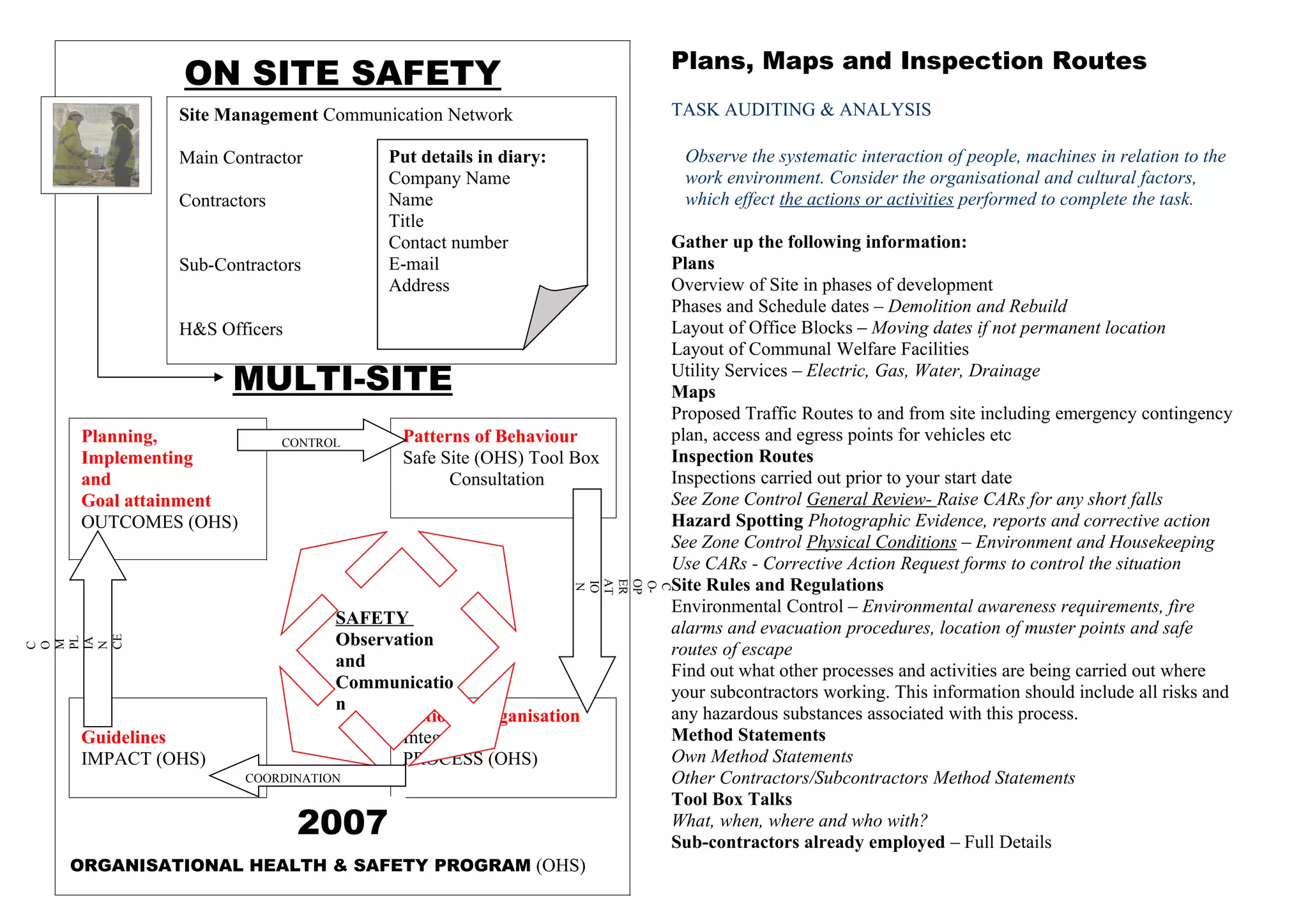

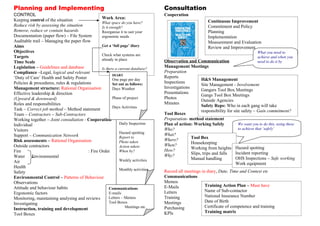

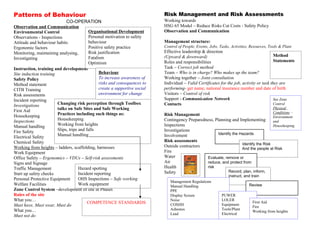

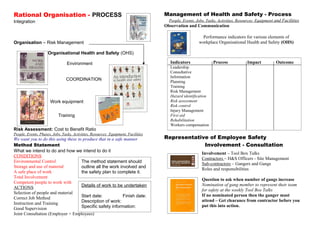

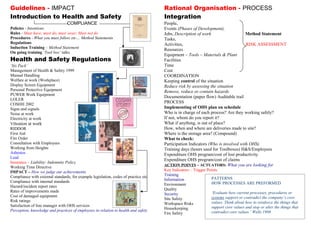

The document provides details on planning health and safety inspections and communication on a construction site. It includes plans for mapping the site layout, inspection routes, communication networks, task auditing, and documenting safety processes. Key information to gather includes schedules, site plans in phases of development, utility locations, traffic routes, inspection reports, and documenting meetings and corrective actions.