Environmental Stress Screening (ESS) is a test designed to uncover weak parts and workmanship defects. It subjects components, subassemblies, or full systems to environmental stresses like thermal cycling and vibration to induce early failures during manufacturing rather than in the field. This improves reliability and maintainability. The adaptive ESS process dynamically adjusts stress levels and times based on failure data to efficiently screen parts at minimum cost. ESS is generally applied during full-scale development and production and selectively during validation to improve outgoing quality and reliability.

![RELIABILITY

ENGINEERING

Environmental Stress Screening (ESS), Continued

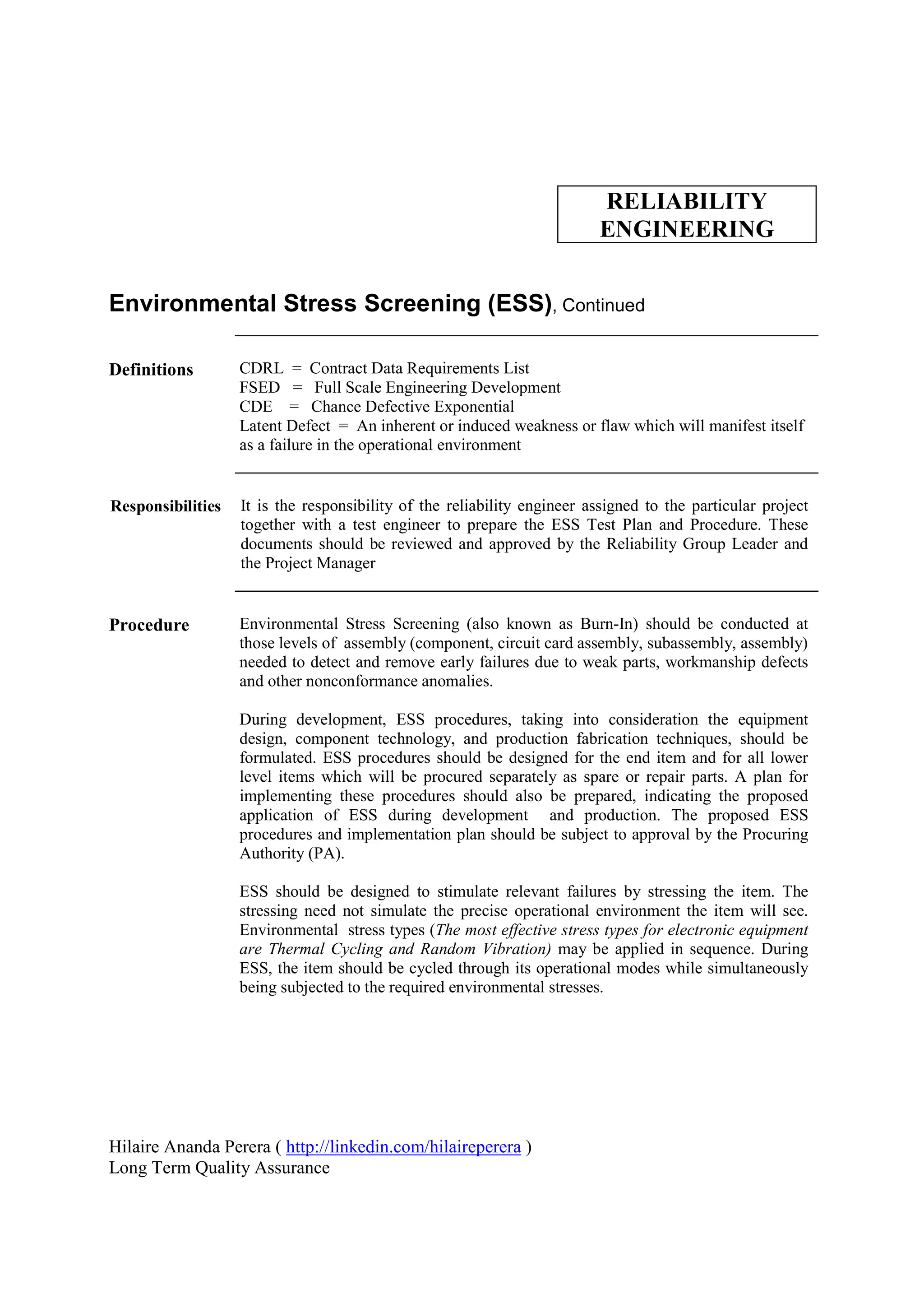

Procedure Upon approval of the proposed ESS procedures and implementation plan, a detailed

(Continued) environmental stress screening process plan should be prepared and included as part

of the reliability test plan. The ESS detailed process plan should include the

following, subject to PA approval prior to initiation of ESS:

• Description of environmental stress types, levels, profiles, and exposure times to

be applied.

• Identification of level (part/component, board, subassembly, assembly) at which

ESS will be accomplished

• Identification of item performance and stress parameters to be monitored during

ESS.

• Proposed ESS durations (best ESS exposure, failure-free interval and allowable

cumulative ESS time per item) based on CDE Model application are:

• Let frD be the average failure rate of a defect under a given set of stress

conditions. (frD is determined from the ESS curve)

• Acceleration Factor is defined as the ratio of the Constant Failure Rate of the

ESS Curve to the Predicted Failure Rate or Field Failure Rate. Let Acceleration

Factor = A

• Best ESS Exposure [Time to remove 99.999% of the Latent Defects] =

(-1/frD)*ln(0.00001)

• Failure-Free Time (FFT) for 99.99% ESS Yield @ 90% Lower Confidence

Level = 7/frD [ This is for A=60 or more ]

• If 5% of Operational Life (OL) should not be consumed during ESS when

multiple failures and repairs are encountered, Allowable Cumulative ESS time =

OL*0.05/A

• Method of incorporating ESS results into FRACAS to attain the needed

operational reliability (MIL-STD-785B Task 104 )

Hilaire Ananda Perera ( http://linkedin.com/hilaireperera )

Long Term Quality Assurance](https://image.slidesharecdn.com/environmentalstressscreening-130118155947-phpapp01/75/Environmental-stress-screening-4-2048.jpg)