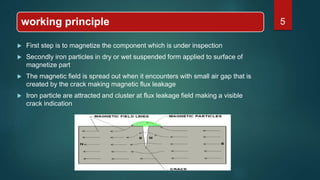

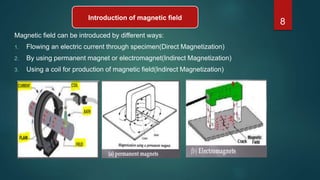

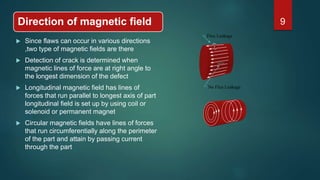

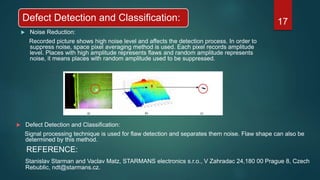

This document summarizes an automated system for magnetic particle inspection of railway wheels. The system uses magnetic particles and high resolution digital cameras to detect surface cracks as small as 1mm in length. It magnetizes the wheel using coils, then coats it with fluorescent particles. Defects are visible under ultraviolet light and scanned by a digital camera. Signal processing techniques are used to detect flaws and separate them from noise. The automated system allows for highly reliable inspection to prevent railway accidents.