The document provides an overview of MRP (Material Requirements Planning) processes in SAP, including:

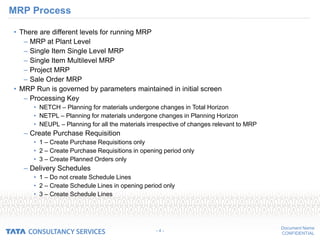

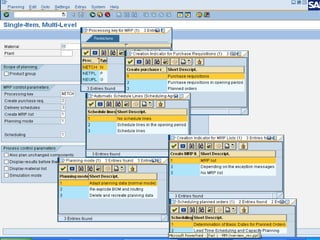

- Different levels of running MRP like plant, single item, project, and sale order levels

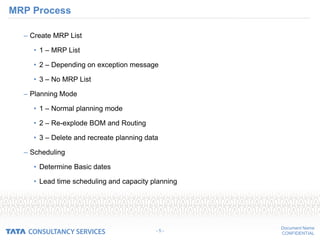

- Parameters that govern the MRP run like processing key, whether to create purchase requisitions or schedules, and planning mode

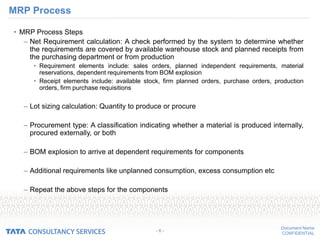

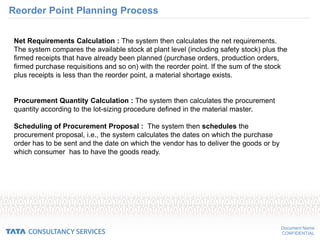

- The steps in the MRP process including net requirement calculation, lot sizing calculation, and procurement type determination

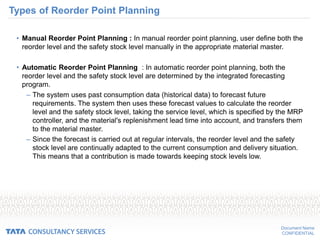

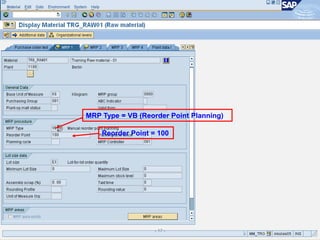

- Consumption-based planning using reorder point or forecast-based approaches

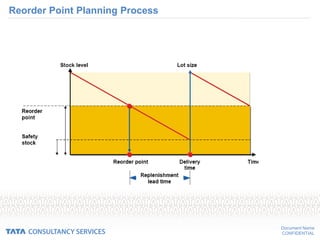

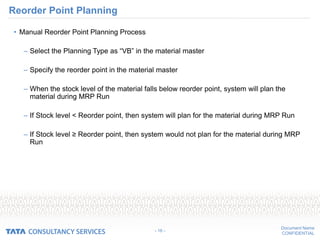

- Reorder point planning process where procurement is triggered when stock plus receipts fall below reorder point

- Types of reorder point planning like manual or automatic

- Lot sizing procedures for calculating