Module 4-5S

•Download as PPTX, PDF•

2 likes•1,222 views

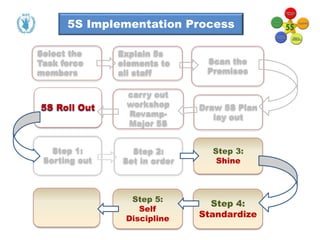

The document provides information on implementing the 5S methodology. It includes: 1. An overview of the 5S implementation process which involves sorting, setting in order, shining, standardizing, and self-discipline. 2. Details on the "shine" element which involves adopting cleaning as a daily activity and inspecting defined areas. 3. Examples of ways to prevent dirty floors like using oil collection mats and locating waste oil tanks outside work areas. 4. Actions needed to standardize processes like developing visual controls and assigning responsibilities. 5. The importance of self-discipline which includes recognizing 5S achievements to create good habits.

Report

Share

Report

Share

Recommended

5S Methodology

In this slide presentation we will examine the 5S Methodology. This methodology provides a sound structure to proceed with any project, professional or personal. Please Like It and Share It with your community.

5S - A step-by-step approach to implement 5S at your workplace

This document "A step-by-step approach to implement 5S at your workplace" is a part of the training material we provide to our clients. This is specifically about the implementation of 5S at your workplace.

Recommended

5S Methodology

In this slide presentation we will examine the 5S Methodology. This methodology provides a sound structure to proceed with any project, professional or personal. Please Like It and Share It with your community.

5S - A step-by-step approach to implement 5S at your workplace

This document "A step-by-step approach to implement 5S at your workplace" is a part of the training material we provide to our clients. This is specifically about the implementation of 5S at your workplace.

How to implement 5S - Japanese technique presentation by netpeckers managemen...

Training presentation on 5S- Japnese technique.

Improvement of Plant Layout by using 5S technique-An industrial case study

5S is one of the most widely adopted techniques from the lean manufacturing toolbox. Along with Standard Work and Total Productive Maintenance, 5S is considered a "foundational" lean concept, as it establishes the operational stability required for making and sustaining continuous improvements. The primary objective of 5S is to create a clean, orderly environment- an environment where there is a place for everything and everything is in its place. Beyond this, many companies begin their lean transformation with 5S because it exposes some of the most visible examples of waste it also helps establish the framework and discipline required to successfully pursue other continuous improvement initiatives

5-S Methodology - ADDVALUE - Nilesh Arora

Find details about TFM first tool Lean 5S Introduction and Methodology by AddValue Consulting.

5s.presentation akash

5S represents 5 disciplines for maintaining a visual workplace (visual controls and information systems).

These are foundational to Kaizen (continuous improvement) and a manufacturing strategy based "Lean Manufacturing" (waste removing) concepts.

QCL-15-V4_[ChallengeNo1]_[VJTI]_[NISHKA VIKAS GULATI]![QCL-15-V4_[ChallengeNo1]_[VJTI]_[NISHKA VIKAS GULATI]](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![QCL-15-V4_[ChallengeNo1]_[VJTI]_[NISHKA VIKAS GULATI]](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

We have written the problems due to bad 5s practices in a nearby grocery store.

Effective shop floor oranization

Workshop presentation on Shop Floor Organization for furniture manufacturers.

April 24, 2012

Level 2 certificate in lean organisation management techniques powerpoint

This unit covers the 5 main principles of lean and the benefits of a lean environment. The productivity needs analysis process, what it is and how to implement it in a case study. Also how to produce a process map.

This assessment of unit 1 (lean organisation techniques in business) is my interpretation and ideas based on the information provided by the course provider.

This is the 1st of 3 units.

More Related Content

What's hot

How to implement 5S - Japanese technique presentation by netpeckers managemen...

Training presentation on 5S- Japnese technique.

Improvement of Plant Layout by using 5S technique-An industrial case study

5S is one of the most widely adopted techniques from the lean manufacturing toolbox. Along with Standard Work and Total Productive Maintenance, 5S is considered a "foundational" lean concept, as it establishes the operational stability required for making and sustaining continuous improvements. The primary objective of 5S is to create a clean, orderly environment- an environment where there is a place for everything and everything is in its place. Beyond this, many companies begin their lean transformation with 5S because it exposes some of the most visible examples of waste it also helps establish the framework and discipline required to successfully pursue other continuous improvement initiatives

5-S Methodology - ADDVALUE - Nilesh Arora

Find details about TFM first tool Lean 5S Introduction and Methodology by AddValue Consulting.

5s.presentation akash

5S represents 5 disciplines for maintaining a visual workplace (visual controls and information systems).

These are foundational to Kaizen (continuous improvement) and a manufacturing strategy based "Lean Manufacturing" (waste removing) concepts.

QCL-15-V4_[ChallengeNo1]_[VJTI]_[NISHKA VIKAS GULATI]![QCL-15-V4_[ChallengeNo1]_[VJTI]_[NISHKA VIKAS GULATI]](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![QCL-15-V4_[ChallengeNo1]_[VJTI]_[NISHKA VIKAS GULATI]](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

We have written the problems due to bad 5s practices in a nearby grocery store.

Effective shop floor oranization

Workshop presentation on Shop Floor Organization for furniture manufacturers.

April 24, 2012

What's hot (20)

How to implement 5S - Japanese technique presentation by netpeckers managemen...

How to implement 5S - Japanese technique presentation by netpeckers managemen...

Improvement of Plant Layout by using 5S technique-An industrial case study

Improvement of Plant Layout by using 5S technique-An industrial case study

QCL-15-V4_[ChallengeNo1]_[VJTI]_[NISHKA VIKAS GULATI]![QCL-15-V4_[ChallengeNo1]_[VJTI]_[NISHKA VIKAS GULATI]](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![QCL-15-V4_[ChallengeNo1]_[VJTI]_[NISHKA VIKAS GULATI]](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

QCL-15-V4_[ChallengeNo1]_[VJTI]_[NISHKA VIKAS GULATI]

Viewers also liked

Level 2 certificate in lean organisation management techniques powerpoint

This unit covers the 5 main principles of lean and the benefits of a lean environment. The productivity needs analysis process, what it is and how to implement it in a case study. Also how to produce a process map.

This assessment of unit 1 (lean organisation techniques in business) is my interpretation and ideas based on the information provided by the course provider.

This is the 1st of 3 units.

OEE Toolkit Software - product overview april 2013

OEE Toolkit Software - product overview april 2013FullFact Solutions B.V. - Productivity Improvement

OEE Toolkit is powerful OEE software that puts your production team in the drivers' seat. You can collect data in an intuitive and flexible manner with RemoteCollect. Our powerful data capturing software (RemoteCollect) is the heart of the OEE Toolkit. All data can be visualized instantly for operators at the machine or even globally via web-based dashboarding. Real-time monitoring allows immediate knowledge and understanding.

Next, OEE Toolkit visualizes and analyzes your losses. We have designed OEE Toolkit to work for management and operators alike enabling you to both automate your OEE and ensure commitment throughout the company. To the point and powerful analyses will tell you how to interpret your losses and where to start improving production's effectiveness for Continuous Improvement at your plant.

OEE Toolkit is powerful, easy to use, and fully implemented within a few days.

OEE Toolkit - clear, insightful information to minimize your effort and maximize results.

Website: https://fullfact.com/

Contact: sales@fullfact.comOee Explained

Explanation of what OEE and what the Six Big Losses are. Contermeasures to reduce the six losses. Calculation of OEE and six loss. How the XL800 tool can help you measure the components of OEE.

Lean Office 5S : The Next Level

Take 5S to the "Next Level" in the office!

This is an overview of a Team handbook that guides individuals and teams on how to take 5S to the next level. It provides different methods of cutting the clutter out of every day business processes while establishing a foundation for operational excellence.

Level 1: "5S Basics" Introduction to the basics of 5S and how to apply to an office area ( Cubicles, desks, meeting rooms, paper files, etc).

Level 2: " The next Level" This section will guide the team in applying 5S to "Information Clutter".(e-mails, files, reference notes, unused applications, and Company website)

Benefits of Collecting OEE Data with Production Tracking Software

Automated OEE data collection systems remove the inaccuracies, inefficiencies and bias of manual data collection and data entry, enabling manufacturers to more reliably collect important production data needed to make operational decisions. Production tracking software systems, like ShopFloorConnect, track uptime, downtime, the reasons for downtime, production rate, and piece part counts (when applicable). Running an automated shop floor data collection system is like having a team of manufacturing engineers doing a detailed efficiency study of the entire factory - all the time.

5S Implementation - The first step to continuous improvement

Implementing 5S results in obvious improvements within the application area, plus, or even more importantly, in the change of people’s attitude towards their work and towards what they are doing.

5S implementation is the first steps to increase the efficiency in your company and the base for the future improvements.

Integrating OEE and Process Improvement

Using OEE more effectively for Process Improvement, Lean, and Six Sigma initiatives

5S Housekeeping Standard

5S from Theory to Practice are the slides of my lecture to diploma in administrative skills.

The 7 deadly sins of Overall Equipment Effectiveness (OEE)

Overall Equipment Effectiveness (OEE) is an effective methodology to help improve the productivity of manufacturing processes and accurately measure true plant productivity. Its measureable components are availability, performance and quality.

Having an automated OEE system can provide

accurate data which can highlight significant

production improvement opportunities. However,

OEE can be complex and there are some pit falls

you should avoid to ensure that your expectations

are met and that a rapid Return On Investment (ROI)

is achieved. Explore the 7 deadly sins of OEE…

5s Lean Presentation

This presentation is based on the book ”Succeeding with 5S” by Oskar Olofsson

Download the presentation together with templates and tools from world-class-manufacturing.com

Viewers also liked (20)

Level 2 certificate in lean organisation management techniques powerpoint

Level 2 certificate in lean organisation management techniques powerpoint

OEE Toolkit Software - product overview april 2013

OEE Toolkit Software - product overview april 2013

Benefits of Collecting OEE Data with Production Tracking Software

Benefits of Collecting OEE Data with Production Tracking Software

5S Implementation - The first step to continuous improvement

5S Implementation - The first step to continuous improvement

The 7 deadly sins of Overall Equipment Effectiveness (OEE)

The 7 deadly sins of Overall Equipment Effectiveness (OEE)

Similar to Module 4-5S

Step-By-Step Approach in implementing 5S in your factory

This document provides a step-by-step approach to implement 5S across your factory. Contents are explained in simple language to help the readers understand 5S and implement in their factories.

Autonomous_Maintenance_Part_1.pptx

We are facing Below mentioned issue on M- 1& M-3 Lines since from long time

1) The Mussing PLC goes in holt mode at the time of starting the cell.

It will take few minutes to restart after repeatedly switching on – off. at the beginning of shift

This problem is savior at two places waz . Down tube and Steering Head. ( M-1 Line)

It is risky from maintenance point of view & there are chances of damaging the PLC permanently

As the Messung has windup their business spares parts management is also a headache for us .

As per discussion with my team members and consequently with you in present scenario we have to replace the Messung PLC by Mitsubishi PLC ( like Installed on M-2 Line) is the only alternative.

I am preparing the action plan for same with my team.

But we need your valuable technical support in this case.

Once the management approves budget and according to production planning we can work out for micro level plan.

Waiting for your support and guidelines. JH ACTIVITES

5s of Production

Production Management PPT

About 5S in operations

Seiri

Seiton

Seiso

Seiketsu

Shitsuke

TOTAL QUALITY MANAGEMENT

A brief discussion of total quality management systems in the textile industry using kaizen,5S, or quality circle

5 S

Explain the 5S process

Go through each “S”

Show tools that can be used for each “S”

Talk about experiences putting the 5S system in place

5 s implementation

The implementation of 5S is visible, requires time and resources and will change the working conditions of many people

It therefore needs to be managed as a real change project with five fairly classic steps: Diagnosis, Prepare the project, Pilot, Implementation and Sustainability.

The implementation of the five actions (Seiri: Sort; Seiton: Set in order; Seiso: Shine; Seiketsu: Standardise; Shitsuke: Sustain) is carried out for the pilot area and then for each of the areas of the implementation phase

5S for Enhancing Productivity, Quality, and Safety at the Workplace

5S is easily understood but difficult to be implemented properly. Persistence, hard work, discipline are required. It will not shown dramatically changed. However, slowly but surely it will make our work easier in a professional way in term of productivity and quality.

TPM for lean manufacturing chp4 step of “jlshu hozen “activities

My Home page is Japanese Gemba Kaizen Web

http://takuminotie.com/english/

Please Look and Like us on Facebook

Table of contents

1. What is Jlshu-Hozen ?

2.Conservation activities of

manufacturing departments

3.Conservation activities

of maintenance department

4.Step method for the development

of “Jishu-Hozen”

Step1: Initial-phase cleaning

Step2:Countermeasures for the source of problems

Step3: Establishment of tentative standards for“Jishu-Hozen”

Step4:General [overall] inspection

Step5: Autonomous inspection

Step6:Standardization

Step 7:Thorough implementation of autonomous

Similar to Module 4-5S (20)

Step-By-Step Approach in implementing 5S in your factory

Step-By-Step Approach in implementing 5S in your factory

Qcl 15-v4 [5 s model]-[scmld]_[ketan, parag,simranjit)![Qcl 15-v4 [5 s model]-[scmld]_[ketan, parag,simranjit)](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![Qcl 15-v4 [5 s model]-[scmld]_[ketan, parag,simranjit)](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

Qcl 15-v4 [5 s model]-[scmld]_[ketan, parag,simranjit)

Qcl 15-v4 [5 s model]-[scmld]_[ketan, parag,simranjit)![Qcl 15-v4 [5 s model]-[scmld]_[ketan, parag,simranjit)](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![Qcl 15-v4 [5 s model]-[scmld]_[ketan, parag,simranjit)](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

Qcl 15-v4 [5 s model]-[scmld]_[ketan, parag,simranjit)

5S for Enhancing Productivity, Quality, and Safety at the Workplace

5S for Enhancing Productivity, Quality, and Safety at the Workplace

TPM for lean manufacturing chp4 step of “jlshu hozen “activities

TPM for lean manufacturing chp4 step of “jlshu hozen “activities

Recently uploaded

What Does the PARKTRONIC Inoperative, See Owner's Manual Message Mean for You...

What Does the PARKTRONIC Inoperative, See Owner's Manual Message Mean for You...Autohaus Service and Sales

Learn what "PARKTRONIC Inoperative, See Owner's Manual" means for your Mercedes-Benz. This message indicates a malfunction in the parking assistance system, potentially due to sensor issues or electrical faults. Prompt attention is crucial to ensure safety and functionality. Follow steps outlined for diagnosis and repair in the owner's manual.Why Isn't Your BMW X5's Comfort Access Functioning Properly Find Out Here

Why Isn't Your BMW X5's Comfort Access Functioning Properly Find Out HereMasters European & Gapanese Auto Repair

In this presentation, we have discussed a very important feature of BMW X5 cars… the Comfort Access. Things that can significantly limit its functionality. And things that you can try to restore the functionality of such a convenient feature of your vehicle.What Causes 'Trans Failsafe Prog' to Trigger in BMW X5

"Trans Failsafe Prog" on your BMW X5 indicates potential transmission issues requiring immediate action. This safety feature activates in response to abnormalities like low fluid levels, leaks, faulty sensors, electrical or mechanical failures, and overheating.

Skoda Octavia Rs for Sale Perth | Skoda Perth

The Octavia range embodies the design trend of the Škoda brand: a fusion of

aesthetics, safety and practicality. Whether you see the car as a whole or step

closer and explore its unique features, the Octavia range radiates with the

harmony of functionality and emotion

Things to remember while upgrading the brakes of your car

Upgrading the brakes of your car? Keep these things in mind before doing so. Additionally, start using an OBD 2 GPS tracker so that you never miss a vehicle maintenance appointment. On top of this, a car GPS tracker will also let you master good driving habits that will let you increase the operational life of your car’s brakes.

欧洲杯比赛投注官网-欧洲杯比赛投注官网网站-欧洲杯比赛投注官网|【网址🎉ac123.net🎉】

欧洲杯比赛投注官网是独立的博彩公司。该公司最初专门从事在线体育博彩,现在合并了在线娱乐场。该公司最初成立时以其前董事长Victor Chandler的名字命名,之后更名为欧洲杯比赛投注官网。欧洲杯比赛投注官网现由商人和赛马主,迈克尔·塔博尔拥有,运营总部设在直布罗陀。平台拥有体育博彩(沙巴)、真人娱乐场、电子游戏、金融投注等游戏项目,支持手机投注,优惠活动很丰富。

一比一原版(AIS毕业证)奥克兰商学院毕业证成绩单如何办理

AIS毕业证【微信95270640】《如何办理AIS毕业证奥克兰商学院文凭学历》【Q微信95270640】《奥克兰商学院文凭学历证书》《奥克兰商学院毕业证书与成绩单样本图片》毕业证书补办 Fake Degree做学费单《毕业证明信-推荐信》成绩单,录取通知书,Offer,在读证明,雅思托福成绩单,真实大使馆教育部认证,回国人员证明,留信网认证。网上存档永久可查!

如果您是以下情况,我们都能竭诚为您解决实际问题:【公司采用定金+余款的付款流程,以最大化保障您的利益,让您放心无忧】

1、在校期间,因各种原因未能顺利毕业,拿不到官方毕业证+微信95270640

2、面对父母的压力,希望尽快拿到奥克兰商学院奥克兰商学院毕业证学历书;

3、不清楚流程以及材料该如何准备奥克兰商学院奥克兰商学院毕业证学历书;

4、回国时间很长,忘记办理;

5、回国马上就要找工作,办给用人单位看;

6、企事业单位必须要求办理的;

面向美国乔治城大学毕业留学生提供以下服务:

【★奥克兰商学院奥克兰商学院毕业证学历书毕业证、成绩单等全套材料,从防伪到印刷,从水印到钢印烫金,与学校100%相同】

【★真实使馆认证(留学人员回国证明),使馆存档可通过大使馆查询确认】

【★真实教育部认证,教育部存档,教育部留服网站可查】

【★真实留信认证,留信网入库存档,可查奥克兰商学院奥克兰商学院毕业证学历书】

我们从事工作十余年的有着丰富经验的业务顾问,熟悉海外各国大学的学制及教育体系,并且以挂科生解决毕业材料不全问题为基础,为客户量身定制1对1方案,未能毕业的回国留学生成功搭建回国顺利发展所需的桥梁。我们一直努力以高品质的教育为起点,以诚信、专业、高效、创新作为一切的行动宗旨,始终把“诚信为主、质量为本、客户第一”作为我们全部工作的出发点和归宿点。同时为海内外留学生提供大学毕业证购买、补办成绩单及各类分数修改等服务;归国认证方面,提供《留信网入库》申请、《国外学历学位认证》申请以及真实学籍办理等服务,帮助众多莘莘学子实现了一个又一个梦想。

专业服务,请勿犹豫联系我

如果您真实毕业回国,对于学历认证无从下手,请联系我,我们免费帮您递交

诚招代理:本公司诚聘当地代理人员,如果你有业余时间,或者你有同学朋友需要,有兴趣就请联系我

你赢我赢,共创双赢

你做代理,可以帮助奥克兰商学院同学朋友

你做代理,可以拯救奥克兰商学院失足青年

你做代理,可以挽救奥克兰商学院一个个人才

你做代理,你将是别人人生奥克兰商学院的转折点

你做代理,可以改变自己,改变他人,给他人和自己一个机会的笑连连说记得记得但别忘了拿奖状进城啊考试一结束山娃就迫不及待地给父亲挂电话:爸我拿奖了三好学生接我进城吧父亲果然没有食言第二天就请假回家接山娃离开爷爷奶奶的那一刻山娃又伤心得泪如雨下宛如军人奔赴前线般难舍和悲壮卧空调大巴挤长蛇列车山娃发现车上挤满了叽叽喳喳的同龄人皆一脸惊喜地四处瞅山娃不认识他们也无暇去套近乎一味地跟着父亲昼夜兼程第二天凌晨就辗转到了父亲的城哇父亲的城真的好大好美哟走出广州火车方

Antique Plastic Traders Company Profile

𝘼𝙣𝙩𝙞𝙦𝙪𝙚 𝙋𝙡𝙖𝙨𝙩𝙞𝙘 𝙏𝙧𝙖𝙙𝙚𝙧𝙨 𝙞𝙨 𝙫𝙚𝙧𝙮 𝙛𝙖𝙢𝙤𝙪𝙨 𝙛𝙤𝙧 𝙢𝙖𝙣𝙪𝙛𝙖𝙘𝙩𝙪𝙧𝙞𝙣𝙜 𝙩𝙝𝙚𝙞𝙧 𝙥𝙧𝙤𝙙𝙪𝙘𝙩𝙨. 𝙒𝙚 𝙝𝙖𝙫𝙚 𝙖𝙡𝙡 𝙩𝙝𝙚 𝙥𝙡𝙖𝙨𝙩𝙞𝙘 𝙜𝙧𝙖𝙣𝙪𝙡𝙚𝙨 𝙪𝙨𝙚𝙙 𝙞𝙣 𝙖𝙪𝙩𝙤𝙢𝙤𝙩𝙞𝙫𝙚 𝙖𝙣𝙙 𝙖𝙪𝙩𝙤 𝙥𝙖𝙧𝙩𝙨 𝙖𝙣𝙙 𝙖𝙡𝙡 𝙩𝙝𝙚 𝙛𝙖𝙢𝙤𝙪𝙨 𝙘𝙤𝙢𝙥𝙖𝙣𝙞𝙚𝙨 𝙗𝙪𝙮 𝙩𝙝𝙚 𝙜𝙧𝙖𝙣𝙪𝙡𝙚𝙨 𝙛𝙧𝙤𝙢 𝙪𝙨.

Over the 10 years, we have gained a strong foothold in the market due to our range's high quality, competitive prices, and time-lined delivery schedules.

Why Is Your BMW X3 Hood Not Responding To Release Commands

Experiencing difficulty opening your BMW X3's hood? This guide explores potential issues like mechanical obstruction, hood release mechanism failure, electrical problems, and emergency release malfunctions. Troubleshooting tips include basic checks, clearing obstructions, applying pressure, and using the emergency release.

Empowering Limpopo Entrepreneurs Consulting SMEs.pptx

Comprehensive program for Agricultural Finance, the Automotive Sector, and Empowerment . We will define the full scope and provide a detailed two-week plan for identifying strategic partners in each area within Limpopo, including target areas.:

1. Agricultural : Supporting Primary and Secondary Agriculture

• Scope: Provide support solutions to enhance agricultural productivity and sustainability.

• Target Areas: Polokwane, Tzaneen, Thohoyandou, Makhado, and Giyani.

2. Automotive Sector: Partnerships with Mechanics and Panel Beater Shops

• Scope: Develop collaborations with automotive service providers to improve service quality and business operations.

• Target Areas: Polokwane, Lephalale, Mokopane, Phalaborwa, and Bela-Bela.

3. Empowerment : Focusing on Women Empowerment

• Scope: Provide business support support and training to women-owned businesses, promoting economic inclusion.

• Target Areas: Polokwane, Thohoyandou, Musina, Burgersfort, and Louis Trichardt.

We will also prioritize Industrial Economic Zone areas and their priorities.

Sign up on https://profilesmes.online/welcome/

To be eligible:

1. You must have a registered business and operate in Limpopo

2. Generate revenue

3. Sectors : Agriculture ( primary and secondary) and Automative

Women and Youth are encouraged to apply even if you don't fall in those sectors.

5 Warning Signs Your BMW's Intelligent Battery Sensor Needs Attention

IBS monitors and manages your BMW’s battery performance. If it malfunctions, you will have to deal with an array of electrical issues in your vehicle. Recognize warning signs like dimming headlights, frequent battery replacements, and electrical malfunctions to address potential IBS issues promptly.

What do the symbols on vehicle dashboard mean?

Ever been troubled by the blinking sign and didn’t know what to do?

Here’s a handy guide to dashboard symbols so that you’ll never be confused again!

Save them for later and save the trouble!

Wondering if Your Mercedes EIS is at Fault Here’s How to Tell

Symptoms like intermittent starting and key recognition errors signal potential problems with your Mercedes’ EIS. Use diagnostic steps like error code checks and spare key tests. Professional diagnosis and solutions like EIS replacement ensure safe driving. Consult a qualified technician for accurate diagnosis and repair.

一比一原版(AUT毕业证)奥克兰理工大学毕业证成绩单如何办理

AUT毕业证【微信95270640】奥克兰理工大学毕业证购买,办理AUT成绩单,AUT毕业证制作【Q微信95270640】《奥克兰理工大学毕业证》,AUT毕业证购买,AUT学位证,奥克兰理工大学学位证《AUT成绩单制作》【AUT毕业证文凭 AUT本科 澳洲学历认证原版制作《diploma certificate degree transcript 》【留信网认证,本科,硕士,海归,博士,排名,成绩单】代办国外(海外)澳洲、韩国、加拿大、新西兰等各大学毕业证。 ?我们对海外大学及学院的毕业证成绩单所使用的材料,尺寸大小,防伪结构(包括:水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠。 文字图案浮雕,激光镭射,紫外荧光,温感,复印防伪)都有原版本文凭对照。

[留学文凭学历认证(留信认证使馆认证)奥克兰理工大学毕业证成绩单毕业证证书大学Offer请假条成绩单语言证书国际回国人员证明高仿教育部认证申请学校等一切高仿或者真实可查认证服务。

多年留学服务公司,拥有海外样板无数能完美1:1还原海外各国大学degreeDiplomaTranscripts等毕业材料。海外大学毕业材料都有哪些工艺呢?工艺难度主要由:烫金.钢印.底纹.水印.防伪光标.热敏防伪等等组成。而且我们每天都在更新海外文凭的样板以求所有同学都能享受到完美的品质服务。

国外毕业证学位证成绩单办理方法:

1客户提供办理奥克兰理工大学奥克兰理工大学毕业证成绩单信息:姓名生日专业学位毕业时间等(如信息不确定可以咨询顾问:我们有专业老师帮你查询);

2开始安排制作毕业证成绩单电子图;

3毕业证成绩单电子版做好以后发送给您确认;

4毕业证成绩单电子版您确认信息无误之后安排制作成品;

5成品做好拍照或者视频给您确认;

6快递给客户(国内顺丰国外DHLUPS等快读邮寄)

— — — — 我们是挂科和未毕业同学们的福音我们是实体公司精益求精的工艺! — — — -

一真实留信认证的作用(私企外企荣誉的见证):

1:该专业认证可证明留学生真实留学身份同时对留学生所学专业等级给予评定。

2:国家专业人才认证中心颁发入库证书这个入网证书并且可以归档到地方。

3:凡是获得留信网入网的信息将会逐步更新到个人身份内将在公安部网内查询个人身份证信息后同步读取人才网入库信息。

4:个人职称评审加20分个人信誉贷款加10分。

5:在国家人才网主办的全国网络招聘大会中纳入资料供国家500强等高端企业选择人才。电总将小方桌搁在门口看书写作业有一次山娃坐在门口写作业写着写着竟伏在桌上睡着了迷迷糊糊中山娃似乎听到了父亲的脚步声当他晃晃悠悠站起来时才诧然发现一位衣衫破旧的妇女挎着一只硕大的蛇皮袋手里拎着长铁钩正站在门口朝黑色的屋内张望不好坏人小偷山娃一怔却也灵机一动立马仰起头双手拢在嘴边朝楼上大喊:“爸爸爸——有人找——那人一听朝山娃尴尬地笑笑悻悻地走了山娃立马“嘭的一声将铁门锁死心却咚咚地乱跳当山娃跟父亲有

Digital Fleet Management - Why Your Business Need It?

Fleet management these days is next to impossible without connected vehicle solutions. Why? Well, fleet trackers and accompanying connected vehicle management solutions tend to offer quite a few hard-to-ignore benefits to fleet managers and businesses alike. Let’s check them out!

Recently uploaded (20)

What Does the PARKTRONIC Inoperative, See Owner's Manual Message Mean for You...

What Does the PARKTRONIC Inoperative, See Owner's Manual Message Mean for You...

Why Isn't Your BMW X5's Comfort Access Functioning Properly Find Out Here

Why Isn't Your BMW X5's Comfort Access Functioning Properly Find Out Here

What Causes 'Trans Failsafe Prog' to Trigger in BMW X5

What Causes 'Trans Failsafe Prog' to Trigger in BMW X5

Things to remember while upgrading the brakes of your car

Things to remember while upgrading the brakes of your car

欧洲杯比赛投注官网-欧洲杯比赛投注官网网站-欧洲杯比赛投注官网|【网址🎉ac123.net🎉】

欧洲杯比赛投注官网-欧洲杯比赛投注官网网站-欧洲杯比赛投注官网|【网址🎉ac123.net🎉】

Tyre Industrymarket overview with examples of CEAT

Tyre Industrymarket overview with examples of CEAT

Regeneration of Diesel Particulate Filter in Automobile

Regeneration of Diesel Particulate Filter in Automobile

Why Is Your BMW X3 Hood Not Responding To Release Commands

Why Is Your BMW X3 Hood Not Responding To Release Commands

Empowering Limpopo Entrepreneurs Consulting SMEs.pptx

Empowering Limpopo Entrepreneurs Consulting SMEs.pptx

5 Warning Signs Your BMW's Intelligent Battery Sensor Needs Attention

5 Warning Signs Your BMW's Intelligent Battery Sensor Needs Attention

Bài tập - Tiếng anh 11 Global Success UNIT 1 - Bản HS.doc

Bài tập - Tiếng anh 11 Global Success UNIT 1 - Bản HS.doc

Wondering if Your Mercedes EIS is at Fault Here’s How to Tell

Wondering if Your Mercedes EIS is at Fault Here’s How to Tell

Digital Fleet Management - Why Your Business Need It?

Digital Fleet Management - Why Your Business Need It?

Module 4-5S

- 1. Draw 5S Plan lay out Explain 5s elements to all staff Select the Task force members 5S Implementation Process 5S Roll Out Step 1: Sorting out carry out workshop Revamp- Major 5S Step 2: Set in order Step 3: Shine Scan the Premises Step 5: Self Discipline Step 4: Standardize

- 2. 5S step 3 implementation Shine (Seiso)

- 3. Adopt cleaning as a daily activity and as a part of inspection. Clean the workplace before starting of the job and before closing the job. Put aside 10 or 15 minutes for the same activity per day. Clean and inspect defined areas, workplace, machines and other items. Cleaning indirectly helps to check or inspect each and every part and place. Hence, it should be a habit. Take remedial action to prevent re-occurrence. Schedule as needed paint coating on buildings, floors, machinery and equipment, during non productive times SEISO (SHINE)

- 4. Find ways to prevent dirt and contamination. Sweeping checklists are applied throughout the day for each of the common areas Safety inspections are performed on a regularly scheduled basis Workers should be responsible to clean the machines, tools, work benches in their individual workplace. Sweepers should be responsible for the common areas outside and inside the premises

- 5. Oily floors are a common problem created by: Oil leaking from engines, transmissions and brake systems and spoiling the floor Keeping the transmission and other parts on the floor, spilling the oil. Draining the oil into a pan, spilling it on the floor. Carrying the oil pan to a waste oil drum and carelessly emptying it in the drum. Note the condition of floor in the photograph. Use 5 Whys or cause-and-effect methods to find the root causes of slippery floor and take appropriate corrective and preventive action.

- 6. WHY 1 Used Engine oil is Emptied in a drum manually causing it to spill on the floor Ask "WHY" five times - get to the root cause of why the working bays get dirty Proper oil collector is not used for draining the oil. WHY 2 While carrying it to the drum, oil spills all over the place. WHY 3 The oil drum is located at a long distance WHY 4 Manual transportation of the used engine oil is the main cause of oil Spilling on the floors WHY 5 Root cause Conclusion: The used oil should not be transported manually to the waste oil drum

- 7. Air line to oil drain trolley pump Oil drain trolley with evacuation pump A B c Method of preventing oil spillage on the ground Waste oil tank located outside the working area(hidden from view) PVC /FRP WASTE OIL TANK Waste oil sucked by the purchaser’s tanker Making use of the root cause analysis, the task force came up with the above solution to prevent oil spillage.

- 8. Floor rubber mats can be laid under the car lift to prevent leaking engine and transmission oils spoiling the floor. There is no special rubber quality required, local grades of thick rubber sheets would be ok. The rubber sheet can be washed with a chemical or detergent frequently.

- 9. 5S Step 4 implementation SEIKETSU(STANDARDIZE)

- 10. Wake up Sleeping Beauty !!!!

- 11. SEIKETSU (Standardize) •Establish standards. Develop visual controls to expose abnormality. •integrate with daily work management. •Prevent deterioration using 5W & 1H strategy. Standards improve reliability and consistency.

- 12. Actions items 1. Take “before” photographs.(See module 2 for before photos) 2. Check that the first three S’s are implemented properly. 3. All team activity documents/check lists should be publicly displayed on a 5S board. 4. Establish the routines and standard practices for regularly and systematically repeating the first three S’s. 5. Create procedures and forms for regularly evaluating the status of the first three S’s. 6. Standardize red tag procedures and holding area rules (see Seiri).

- 13. 7. Standardize procedures for creating shadow boards, position lines, and labeling of all items (see Seiton). 8. Standardize cleaning schedules using the “5S Owner Check Sheets” (see Seiso). 9. Standardize “single-point lessons” for documenting and communicating 5S procedures and improvements in workplace and equipment. 10. Create a maintenance system for housekeeping. Make a schedule for cleaning of the workplace. A common approach is to ask a cross-functional team to do it. 11. Inter-departmental competition is an effective means of sustaining and enhancing interest in 5S. 12. Assign responsibility to individuals for a work area and machinery.

- 14. Check out Kaizen suggestion form.xlsx 13. Regular inspection/audit and evaluation by a special team (including senior management persons) to be continued. 14. Instead of criticizing poor cases, praise and commend good practices or good performers. 15. Take “after” photographs and post them on the 5S board(s). 16. Complete evaluation using 5S levels of implementation with the facility manager or the authorized persons in the organization

- 16. •Create an environment through slogans, posters and other visuals •Set an example, from a habit. •Conduct audits to evaluate approach and results. Recognize 5S achievements 5. SHITSUKE (SELF DISCIPLINE) Action speaks louder than the words March04 audit.xls

- 17. Fix up a day when your workshop staff takes a break from the usual boring schedule. Announce at least 3 winners who have scored maximum points in the 5S audit. Distribute T shirts or badges to winners.