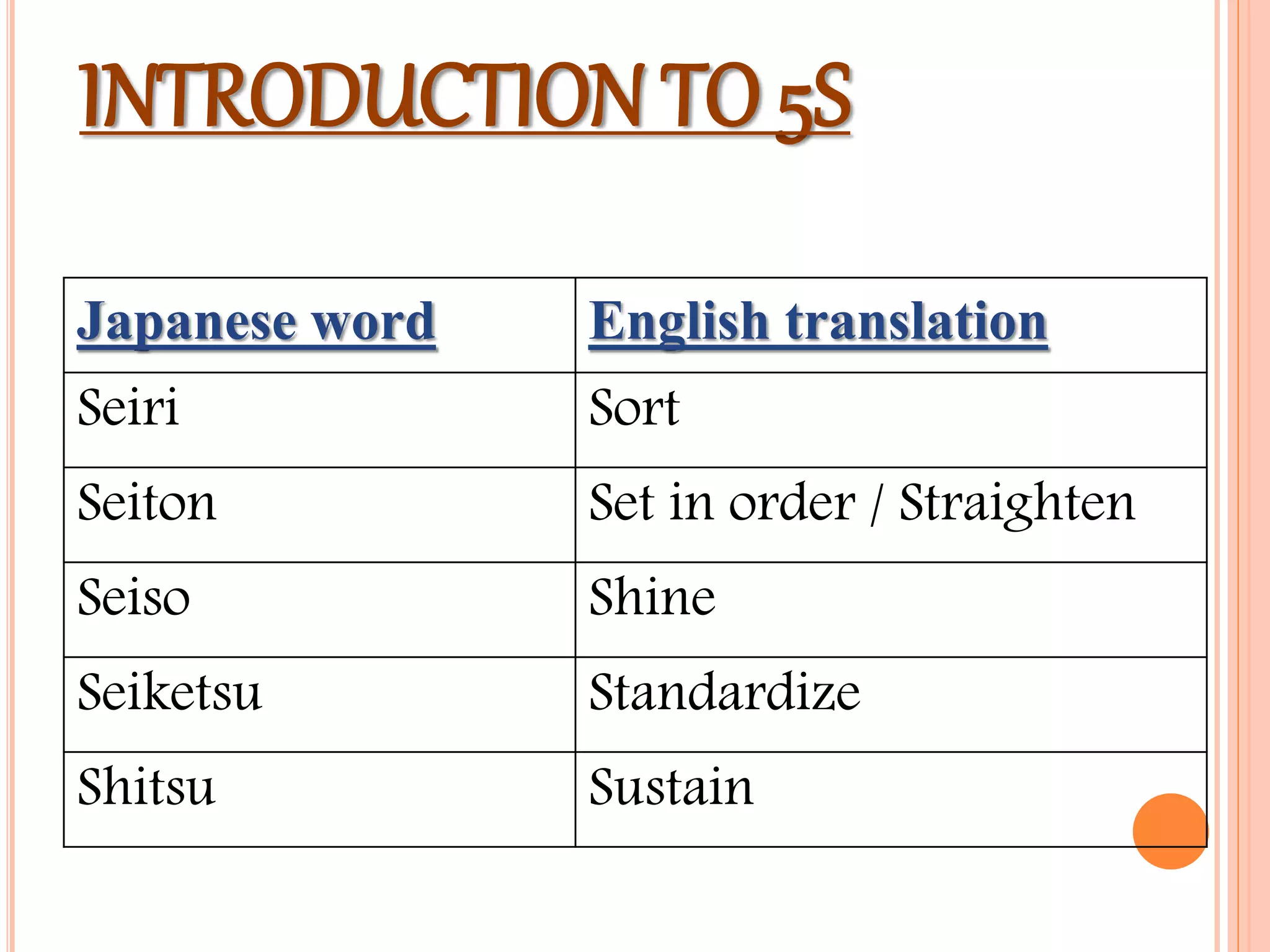

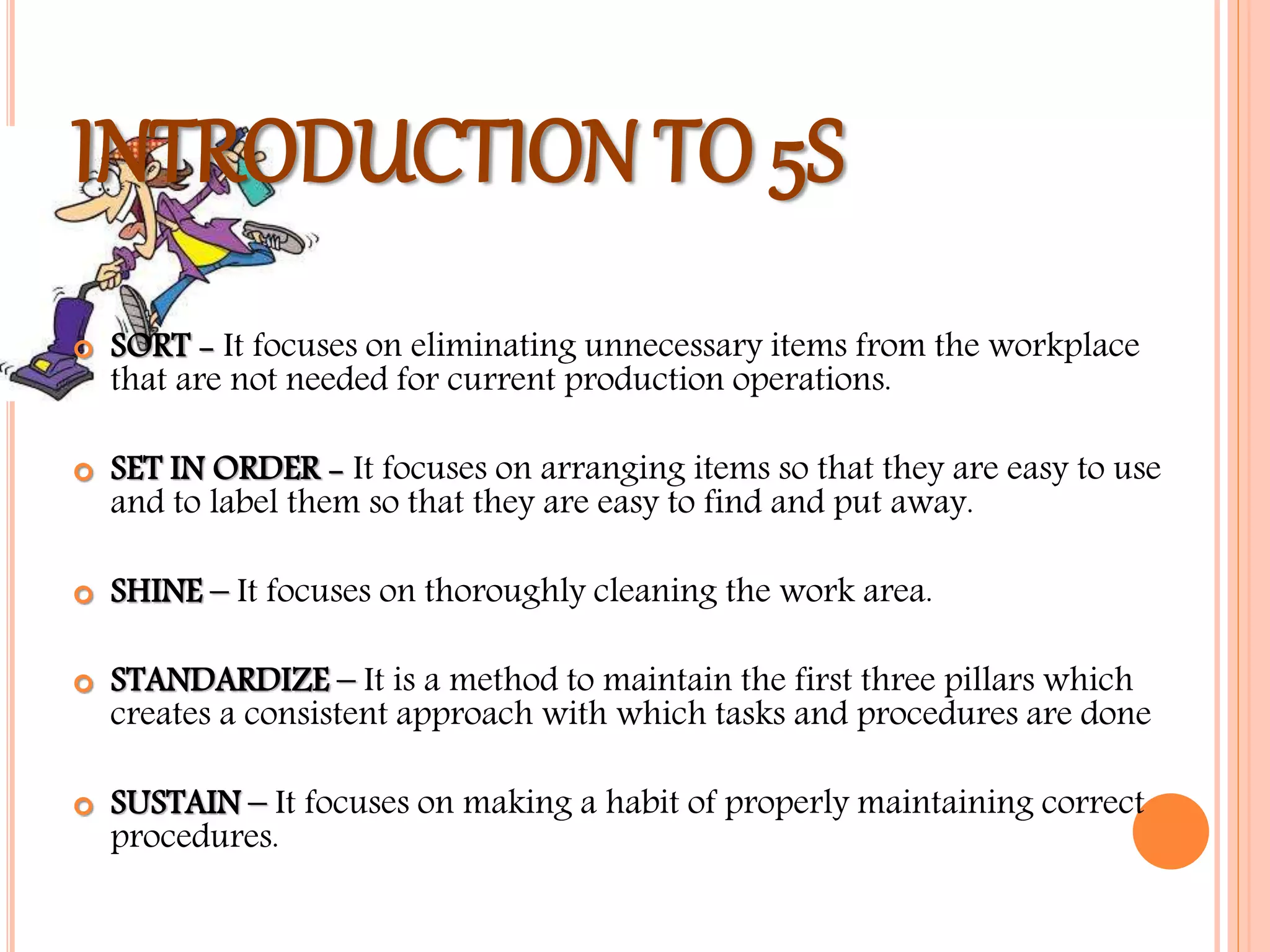

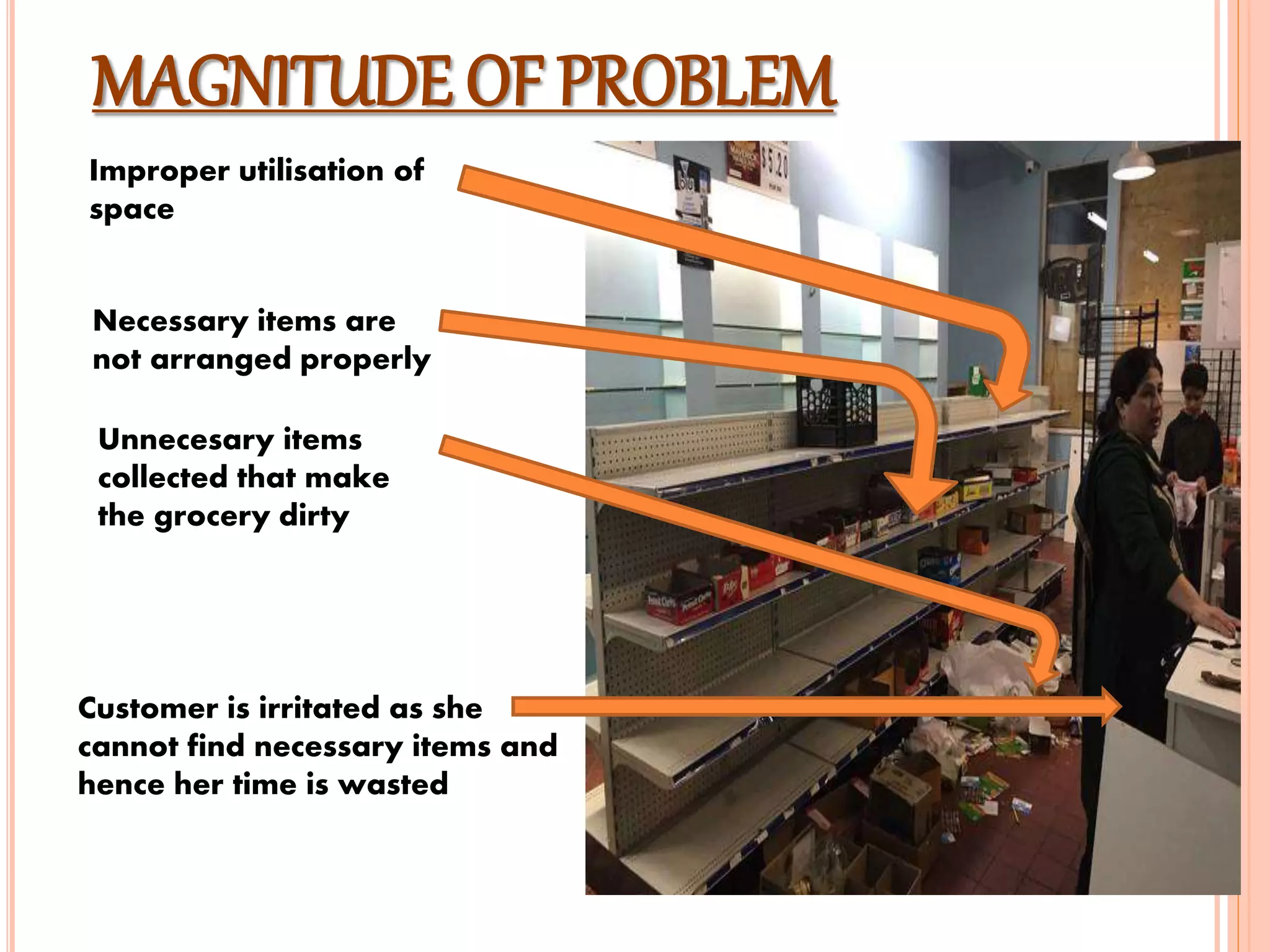

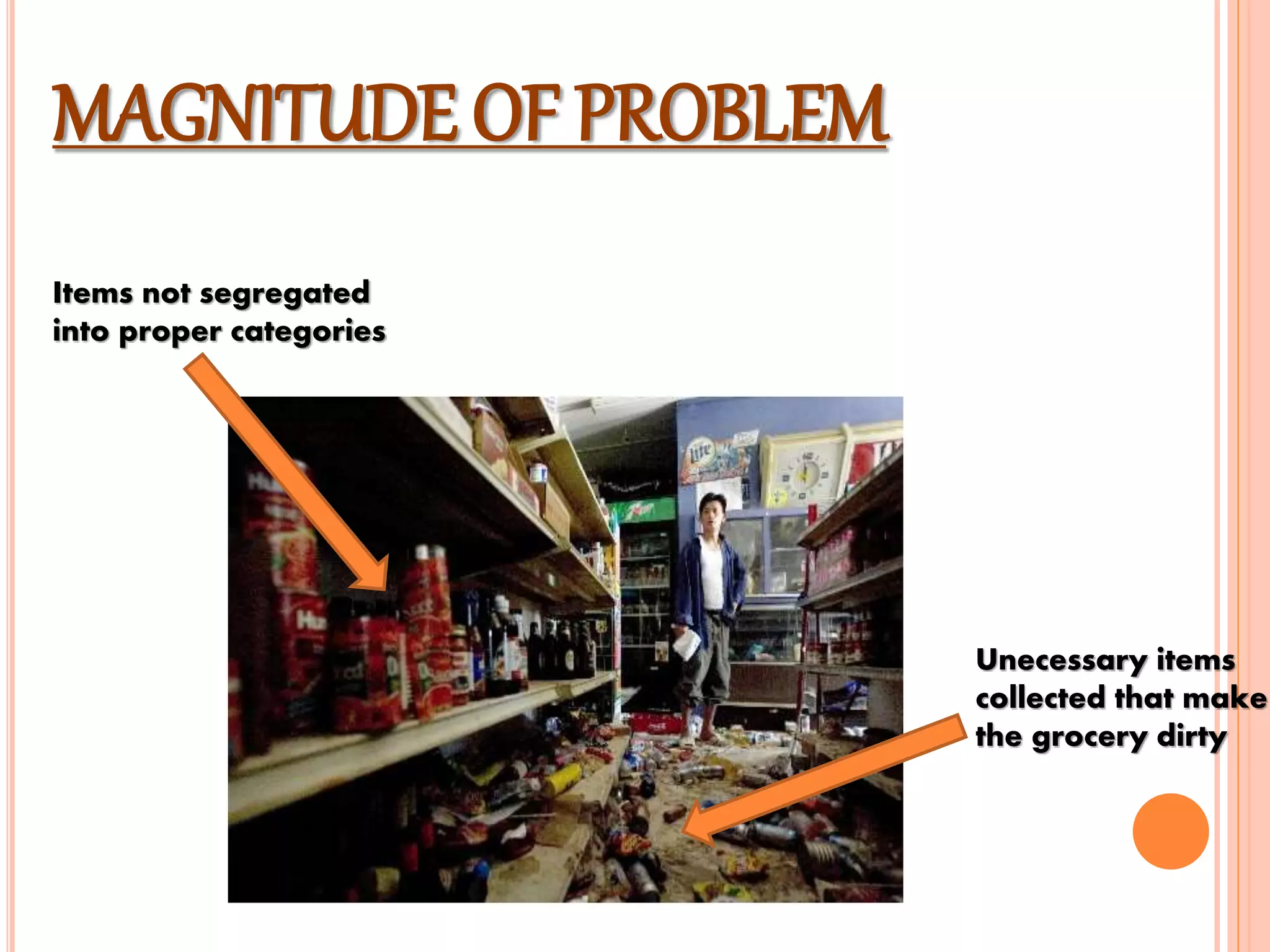

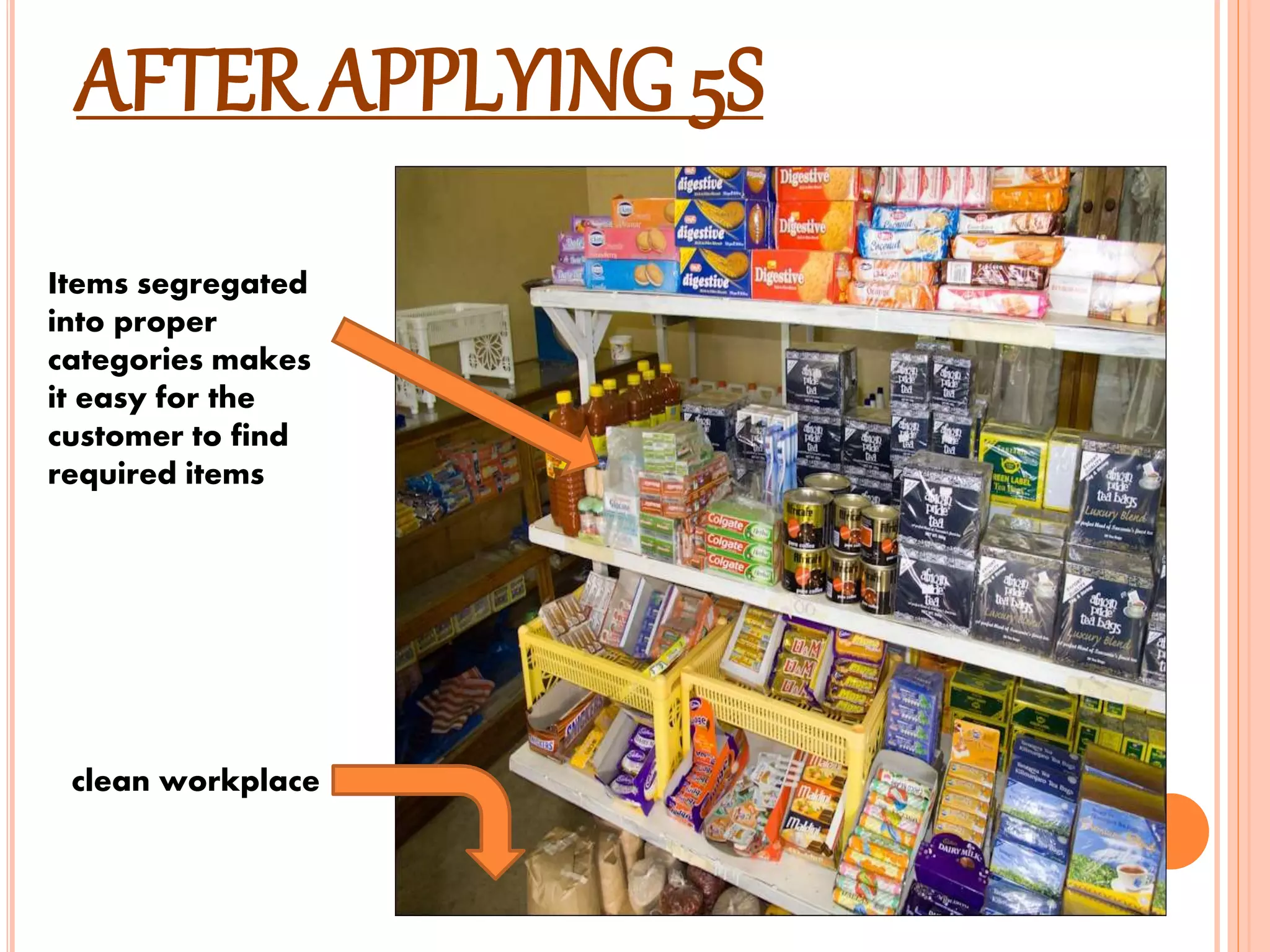

This document discusses applying the 5S methodology in a grocery store. 5S is a system used to organize and clean the workplace. It consists of five steps: sort, set in order, shine, standardize, and sustain. The document analyzes problems with poor 5S practices like disorganization and dirtiness in grocery stores. It provides recommendations for each 5S step like removing unnecessary items and cleaning. Implementing 5S is expected to improve the store's efficiency by making items easier to find and maintaining a cleaner environment.