The document discusses the 5S technique, which is a workplace organization method originally developed in Japan. It consists of five Japanese words that begin with S when translated to English: sort, set in order, shine, standardize, and sustain. The 5S technique aims to organize a workspace for efficiency by identifying necessary items, storing them properly, maintaining cleanliness, standardizing processes, and sustaining the new systems. Implementing 5S can significantly increase productivity by reducing wasted time searching for items and making abnormalities more visible for quick resolution.

![INTRODUCTION[1]

5s is the name of workplace organization

method that uses a list of five japanese words:

• 1.seiri(sort)

• 2.seiton(set in order)

• 3.seiso(shine)

• 4.seiketsu(standardize)

• 5.shitsuke(sustain)

When Translated it into English , they all are

start with letter S.

14mmcm16 06-11-2014

3](https://image.slidesharecdn.com/5stechnique-141105220958-conversion-gate02/85/5-s-technique-3-320.jpg)

![Discovery of 5s [2] :

• Thirty years ago researchers started studying the secret

of success of Japanese manufacturing companies

• 5S turned out to be the most impressive "secret"

• The factories were so well organized that abnormal

situations were readily apparent

• Equipment were so clean and well maintained that any

problem such as a loose bolt or leaking oil could be easily

seen

• This passion of cleanliness and orderliness became a

hallmark of Japanese organizations

14mmcm16 06-11-2014

5](https://image.slidesharecdn.com/5stechnique-141105220958-conversion-gate02/85/5-s-technique-5-320.jpg)

![The 5s principles[3]:

• 1. Sort - All unneeded tools, parts and supplies are

removed from the area

• 2. Set in Order - A place for everything and everything is

in its place

• 3. Shine - The area is cleaned as the work is performed

• 4. Standardize - Cleaning and identification methods are

consistently applied

• 5. Sustain - 5S is a habit and is continually improved

• Also -Work areas are safe and free of hazardous or

dangerous conditions

14mmcm16 06-11-2014

6](https://image.slidesharecdn.com/5stechnique-141105220958-conversion-gate02/85/5-s-technique-6-320.jpg)

![1.seiri(sorting/organizing)[3]

• Decide what you need

• Remove unnecessary clutter

• All tools, gauges, materials, classified and stored

• Remove items which are broken, unusable or only

occasionally used

14mmcm16 06-11-2014

8](https://image.slidesharecdn.com/5stechnique-141105220958-conversion-gate02/85/5-s-technique-8-320.jpg)

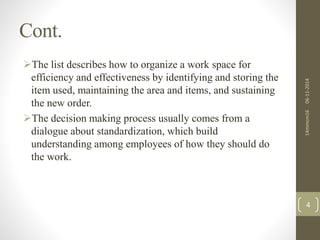

![2.Seiton (straighten/set in order)[3]:

• Organise layout of tools and equipment

• Designated locations

• Use tapes and labels

• Ensure everything is available

as it is needed and

at the “point of use”

14mmcm16 06-11-2014

12

A place for everything and

everything on its place."](https://image.slidesharecdn.com/5stechnique-141105220958-conversion-gate02/85/5-s-technique-12-320.jpg)

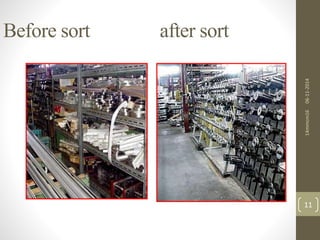

![3.Seiso (shine/sweep/scrub)[3]

• Create a spotless workplace

• Identify and eliminate causes of dirt and grime – remove

the need to clean

• Sweep, dust, polish and paint

14mmcm16 06-11-2014

14](https://image.slidesharecdn.com/5stechnique-141105220958-conversion-gate02/85/5-s-technique-14-320.jpg)

![4.Seiketsu (standardize)[3]:

• Standardize clean-up activities by:

• Sustaining five-minute daily clean up habit

• Keeping a balance between personal

cleanliness and the cleanliness of the

environment / work place

• Avoiding littering. Learning to pick-up tiny pieces of

waste around

• Regularly audit using checklists and measures of

housekeeping

14mmcm16 06-11-2014

18](https://image.slidesharecdn.com/5stechnique-141105220958-conversion-gate02/85/5-s-technique-18-320.jpg)

![5.Shitsuke (sustain/self discipline)[3]:

• Instilling the ability of doing things

the way they are supposed to be done

• Becoming a role model by treating

your work place as your second home

• Influencing others to join in keeping

a well-maintained work place.

• Aiming for constant improvement

14mmcm16 06-11-2014

19

A bad example

of discipline](https://image.slidesharecdn.com/5stechnique-141105220958-conversion-gate02/85/5-s-technique-19-320.jpg)

![Simple task to determine benefit of 5s[4]:

14mmcm16 06-11-2014

22

•In this photo you can see a rack

containing the forms and flyers common

in most HR departments

•Let us assume 600 employees need to go

to this rack from time to time, and say on

an average, everyone does this about three

times a year.

•Each person takes 15 minutes to look

through the rack. How much is the search-hours

?

•With 5S’, it came down easily to a

minute or less per visit

•How much is the increase in productivity

?](https://image.slidesharecdn.com/5stechnique-141105220958-conversion-gate02/85/5-s-technique-22-320.jpg)

![Daily Life Example of 5s[2]:

1. Hang hand towel nearer to sink (seiton)

2. Use CD organizer to organize CDs(seiton)

3. Use letter classifier to sorting the letters

(seiri and seiton)

4. Put instructions on the cover of home appliances like

washing m/c , mixture etc.(shitsuke)

Etc…………….

14mmcm16 06-11-2014

24](https://image.slidesharecdn.com/5stechnique-141105220958-conversion-gate02/85/5-s-technique-24-320.jpg)

![5s in Indian industries[5]:

1. Metalfab high tech private ltd , Nagpur

2. BHEL-Bharat heavy electrical ltd.

3. L & T Larson and Turbo

4. Jyoti CNC

5. Waterman pump

6. Toyota and most of automobile company etc………..

14mmcm16 06-11-2014

25](https://image.slidesharecdn.com/5stechnique-141105220958-conversion-gate02/85/5-s-technique-25-320.jpg)

![Benefits[5]:

Improvements in:-

• Workforce morale

• Company image

• Health and Safety

• Machine maintenance

• Quality

• Productivity

• Leading to Increased Competitiveness

14mmcm16 06-11-2014

27](https://image.slidesharecdn.com/5stechnique-141105220958-conversion-gate02/85/5-s-technique-27-320.jpg)