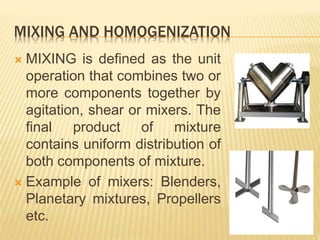

Mixing is the process of combining two or more components through agitation to create a uniform mixture. There are several types of mixers that can be used for different applications depending on whether solids, liquids, or semisolids are being mixed. The key goals of mixing are to obtain a uniform composition and enhance reactions between components. Factors like particle size and shape, density, mixing time and mechanism influence the mixing process. Homogenization further breaks down mixtures to reduce particle size and create a more uniform dispersion.