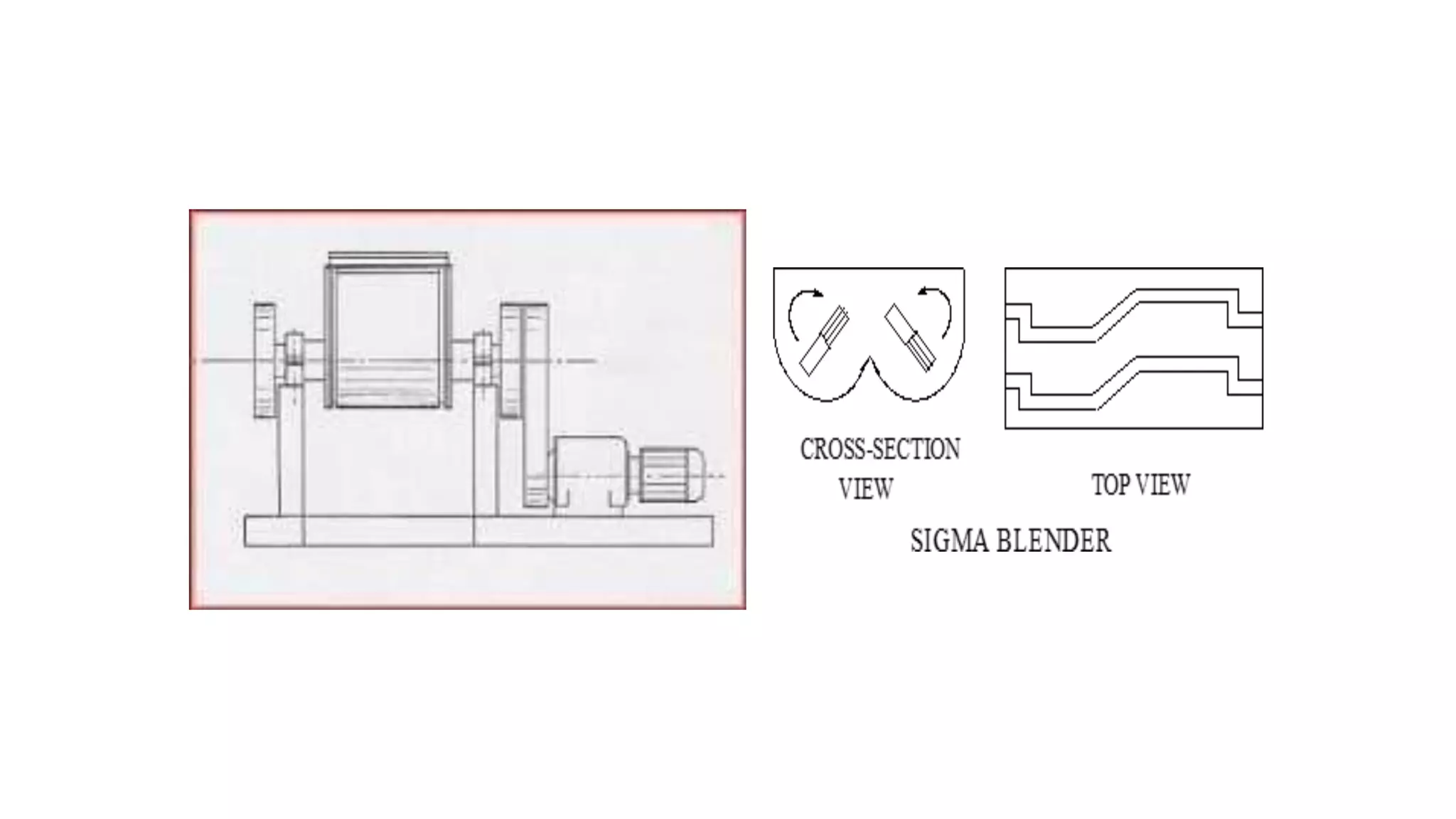

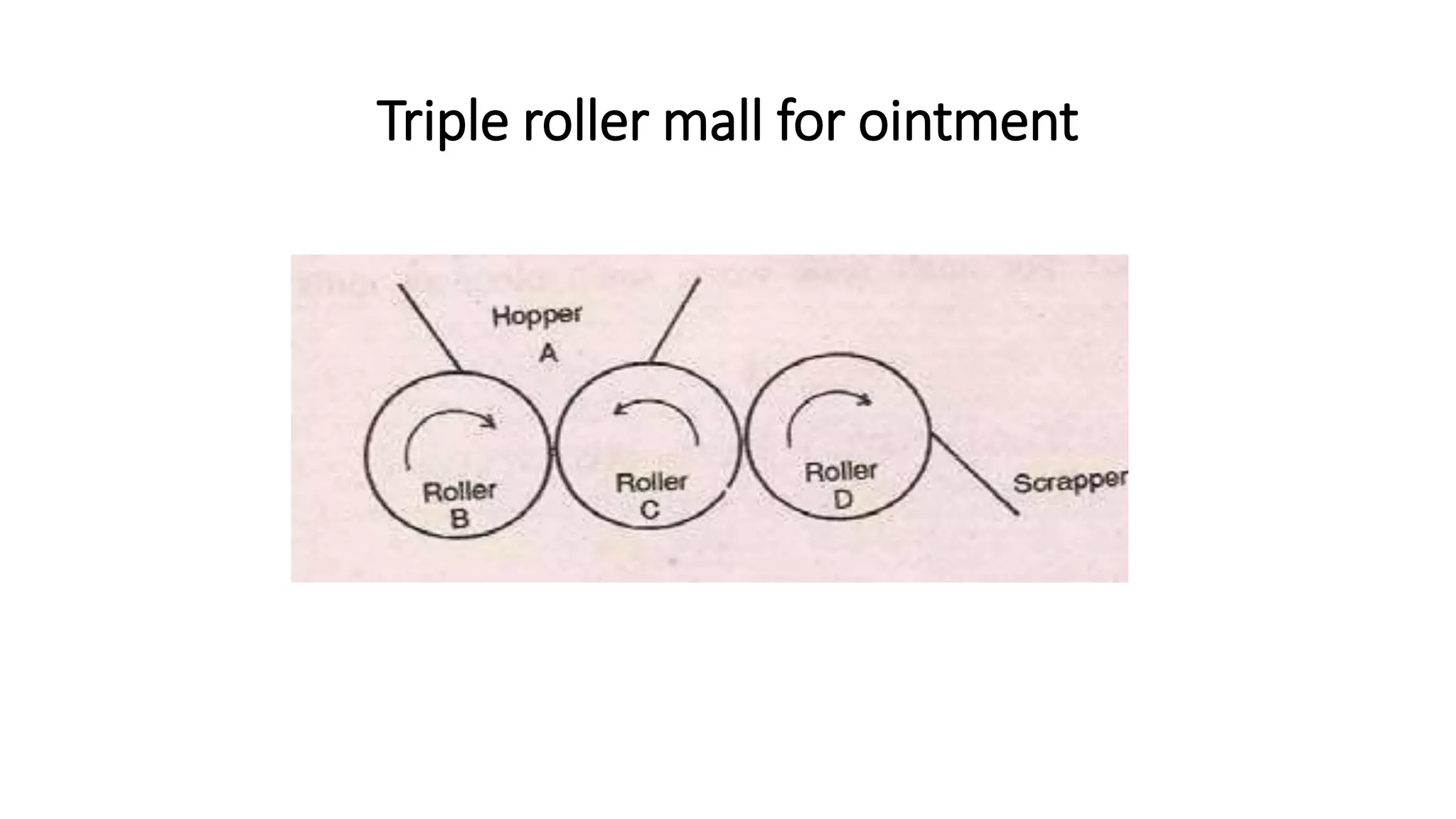

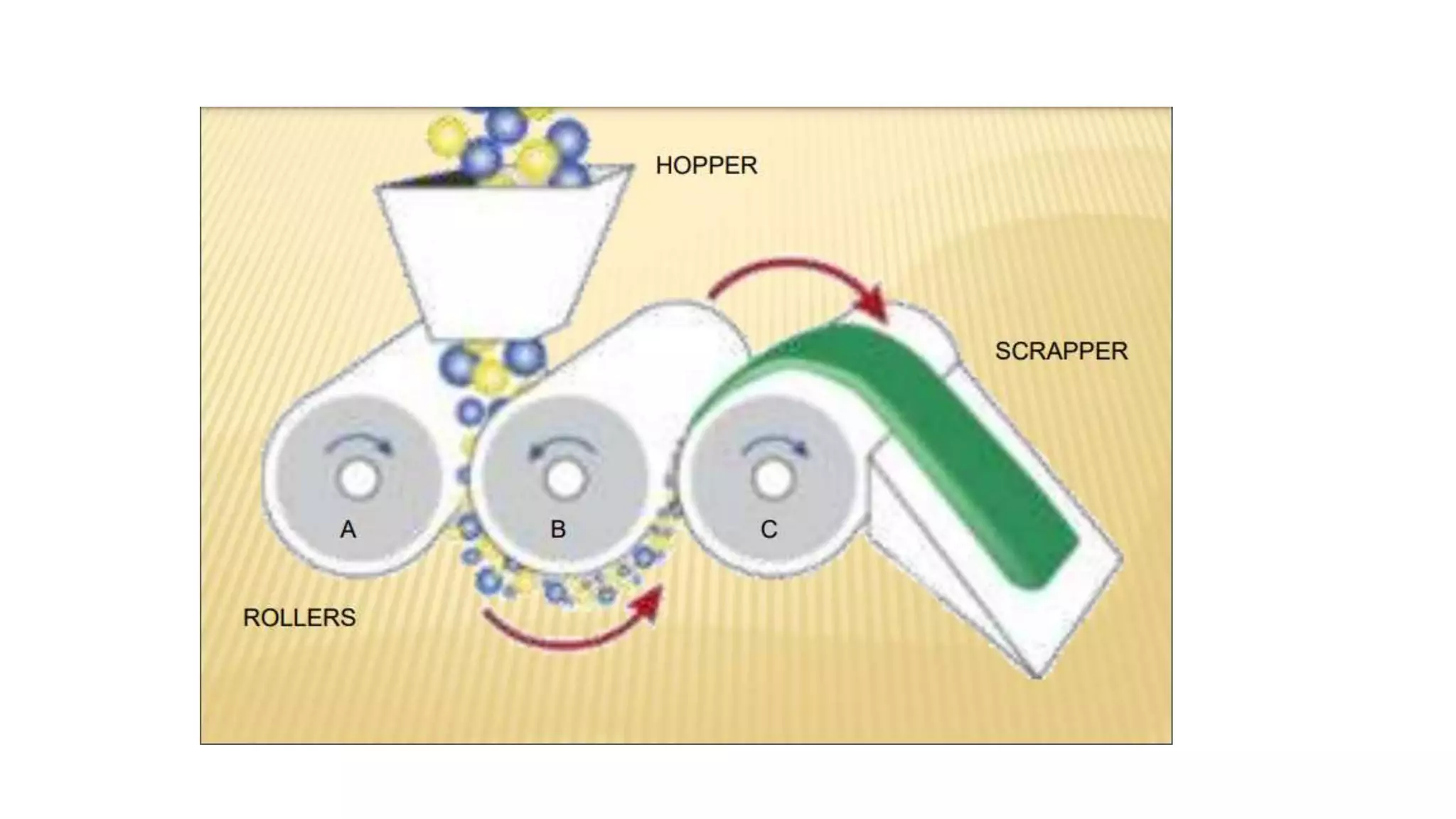

This document discusses various types of mixers used in the pharmaceutical industry for mixing liquids, solids, and semi-solids. It describes planetary mixers and sigma blade mixers, which are commonly used agitator mixers. Planetary mixers mix through an orbiting motion, while sigma blade mixers use two blades rotating towards each other. Triple roller mills are also discussed as shear mixers used for size reduction and mixing ointments into a smooth texture. The key factors affecting mixing and various applications are summarized.