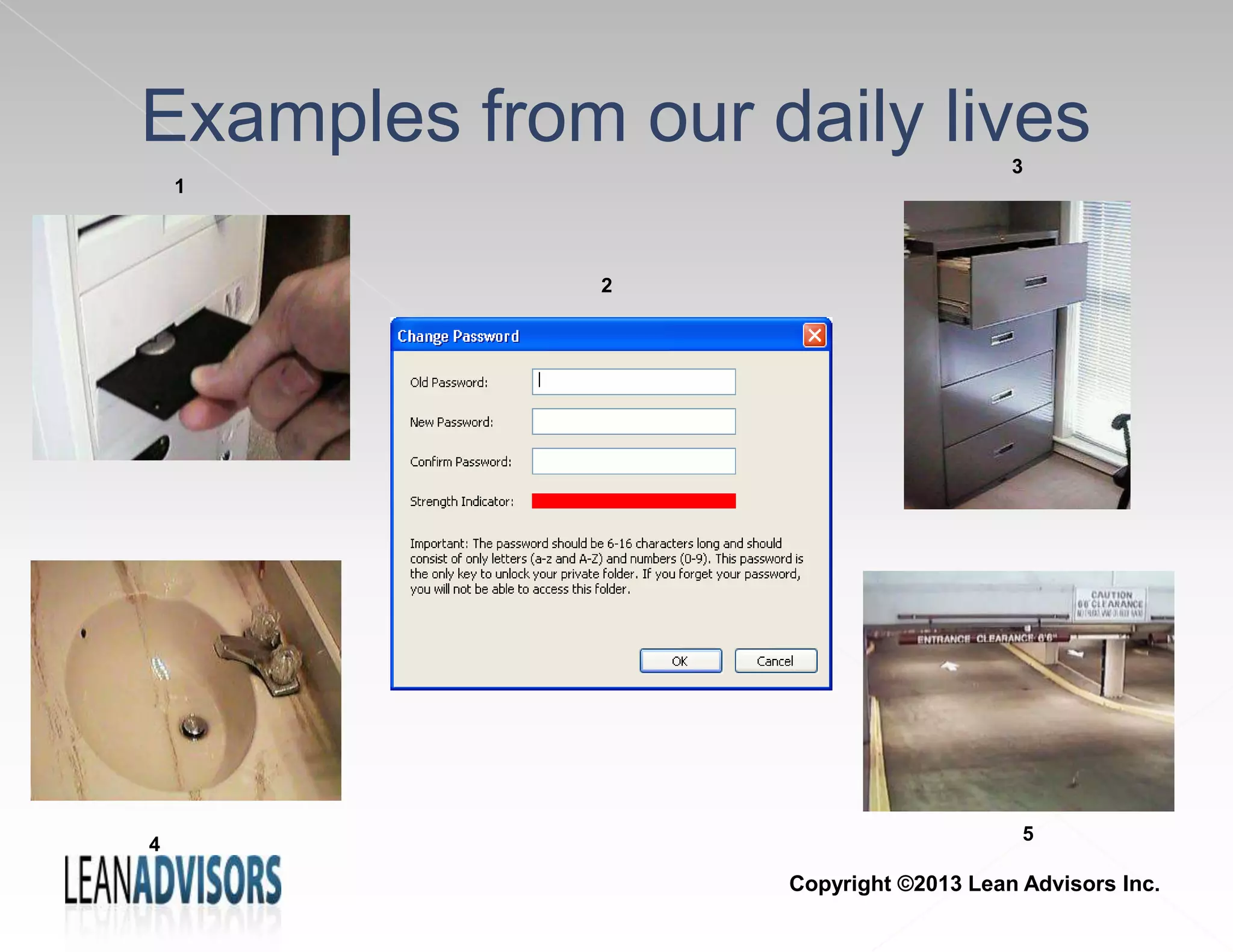

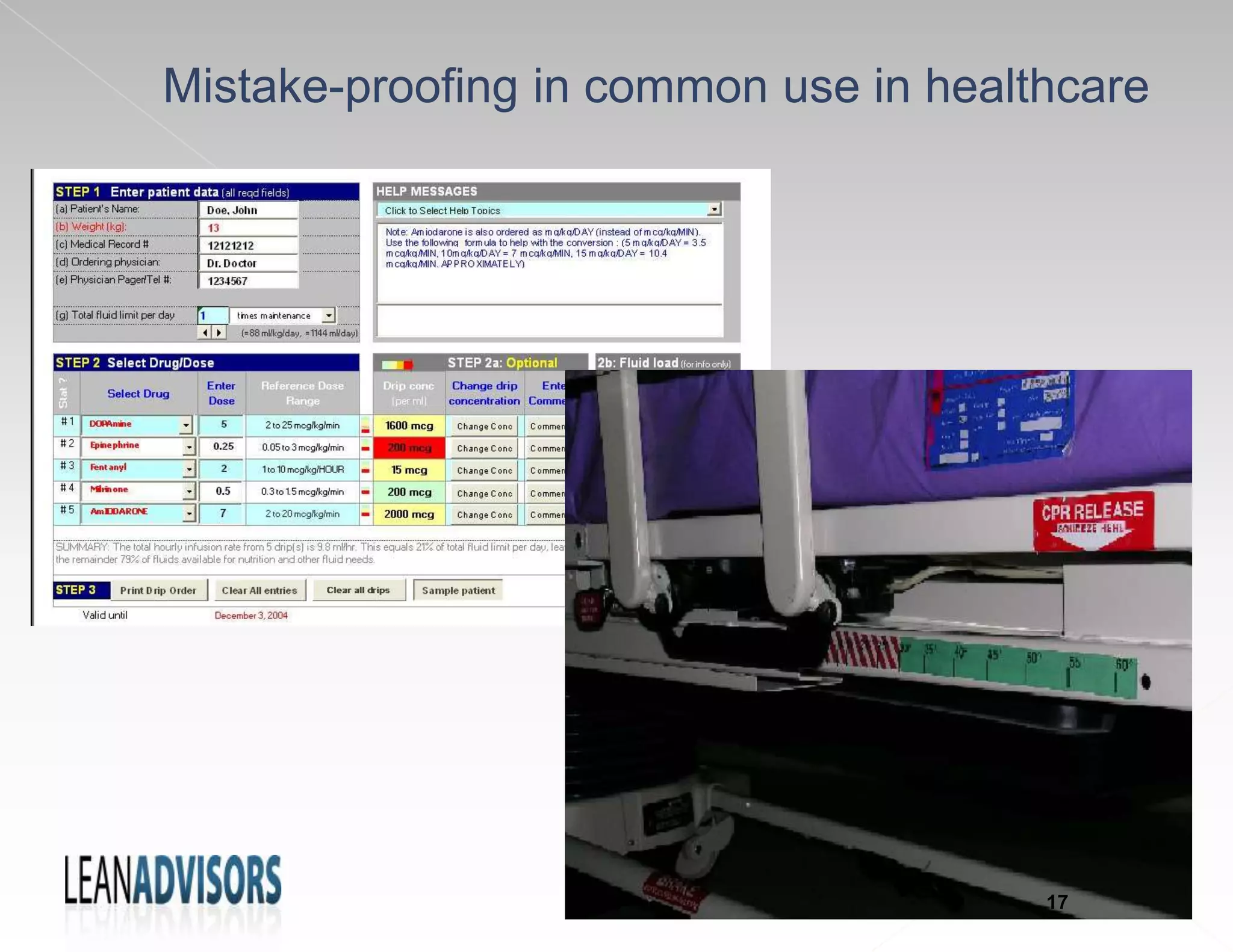

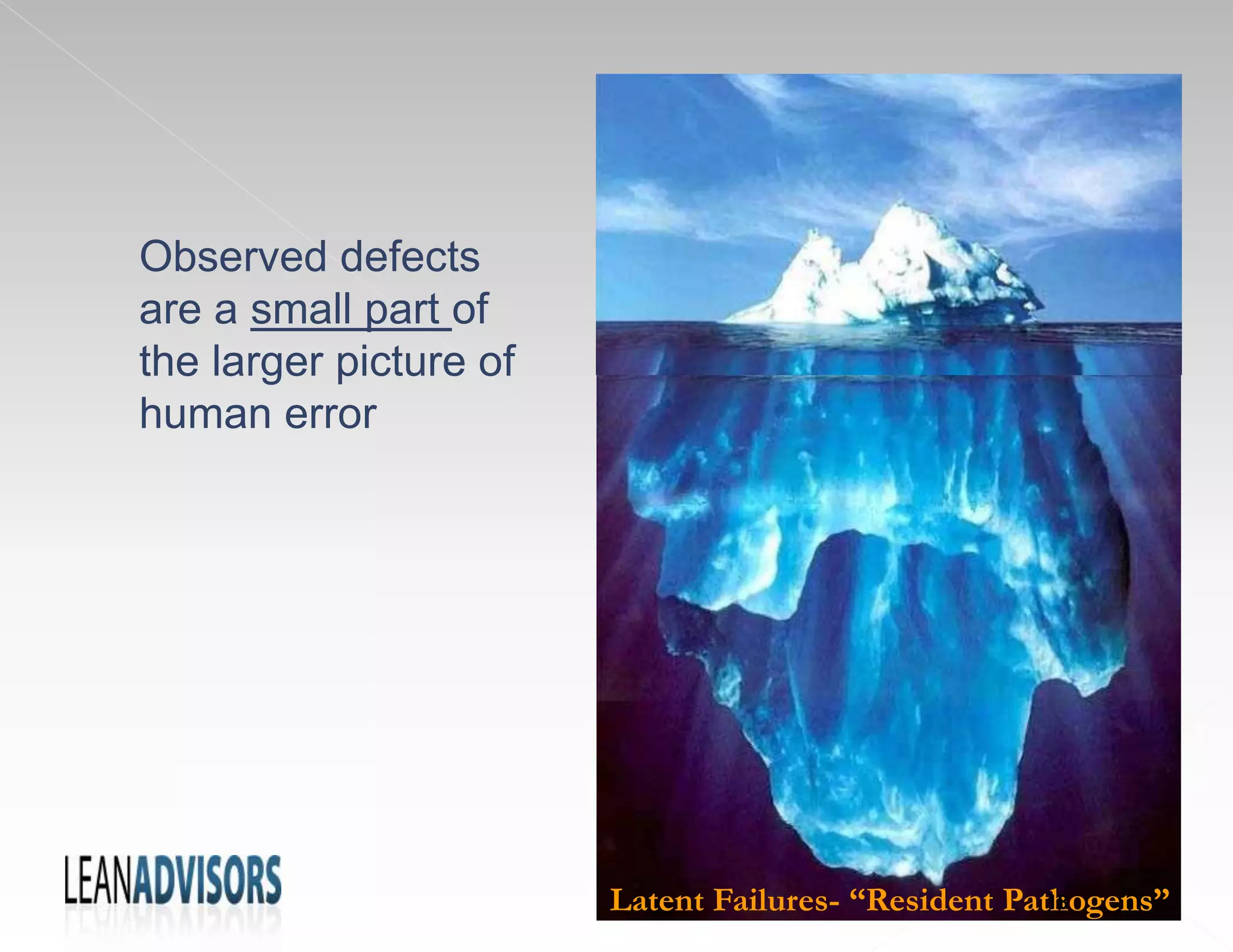

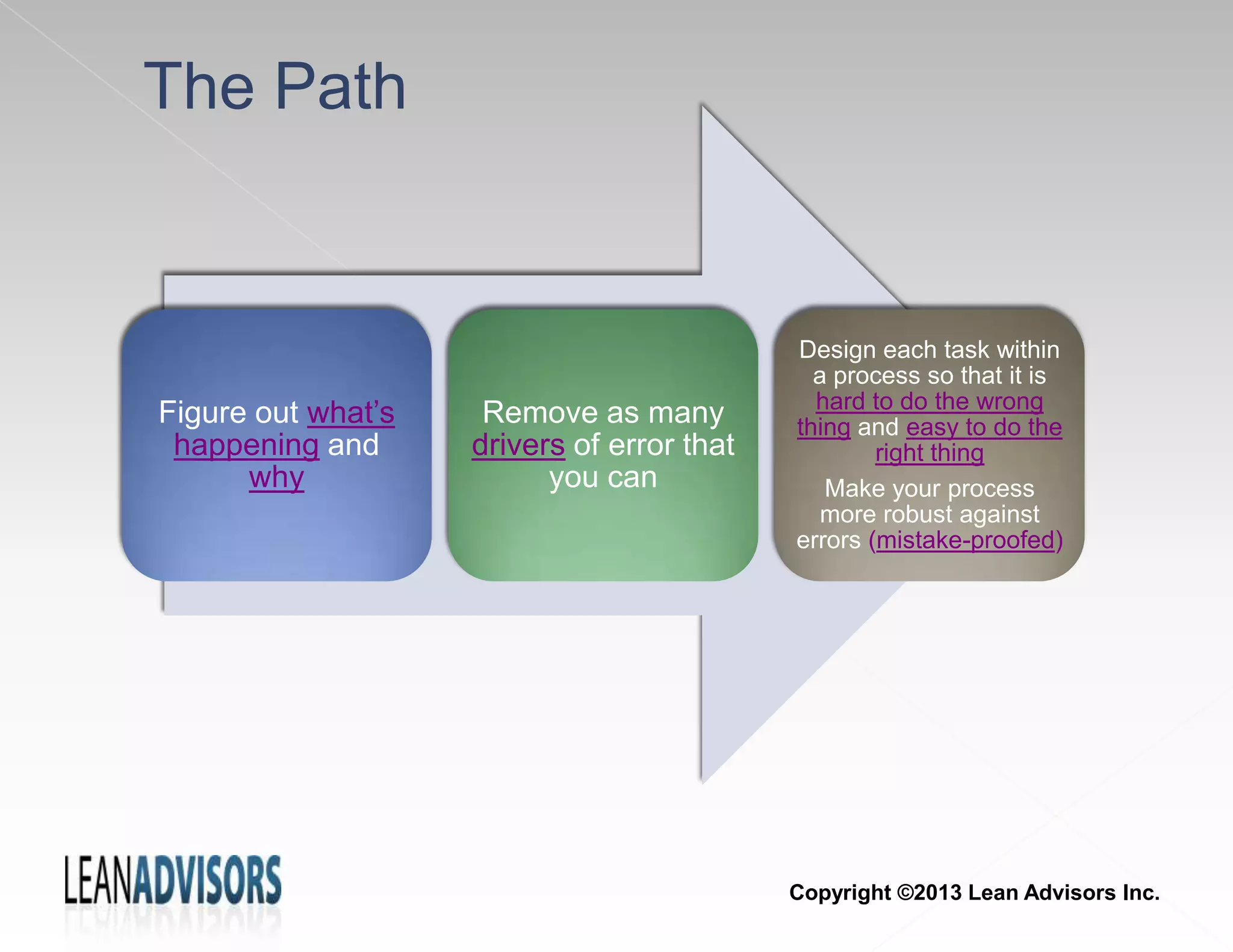

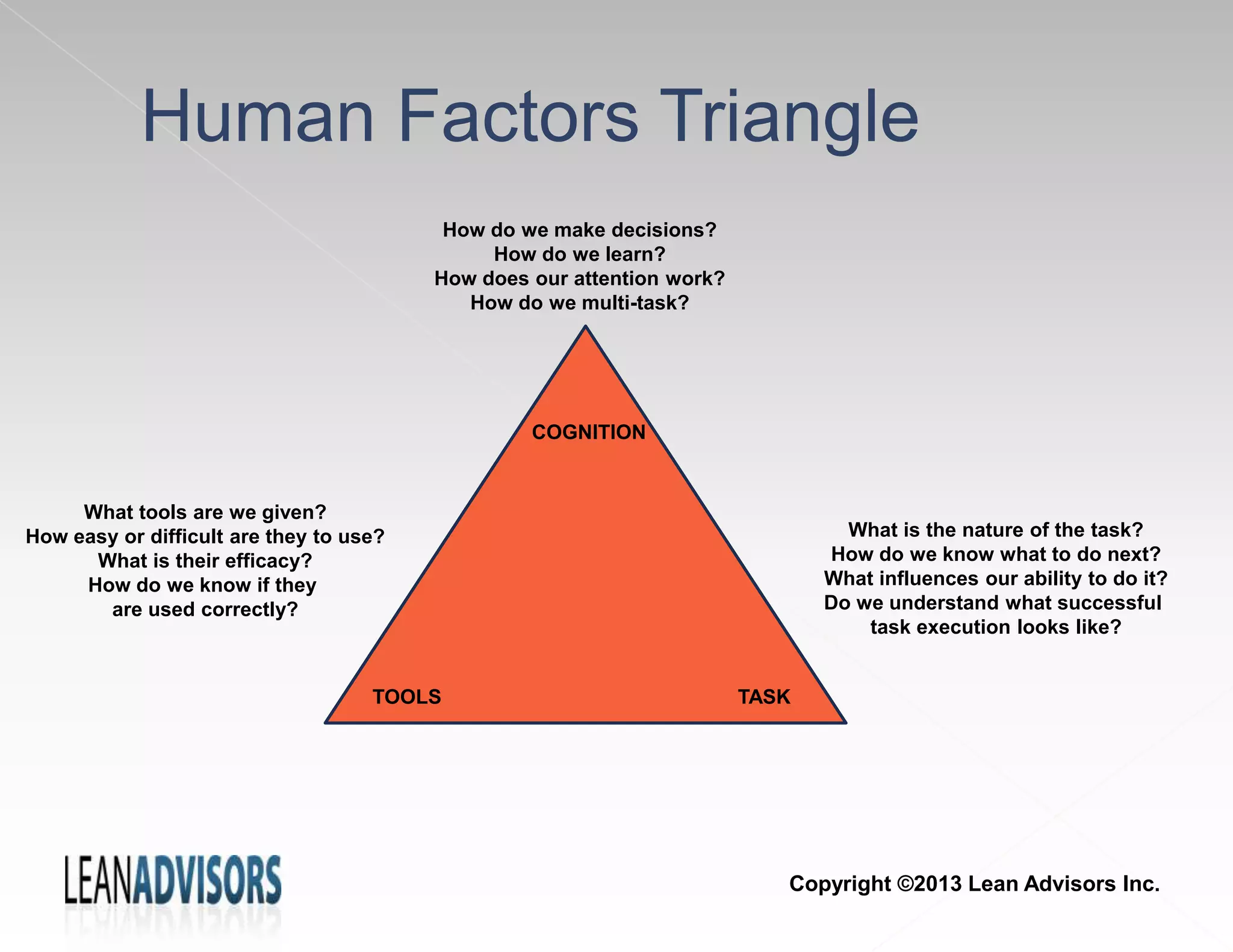

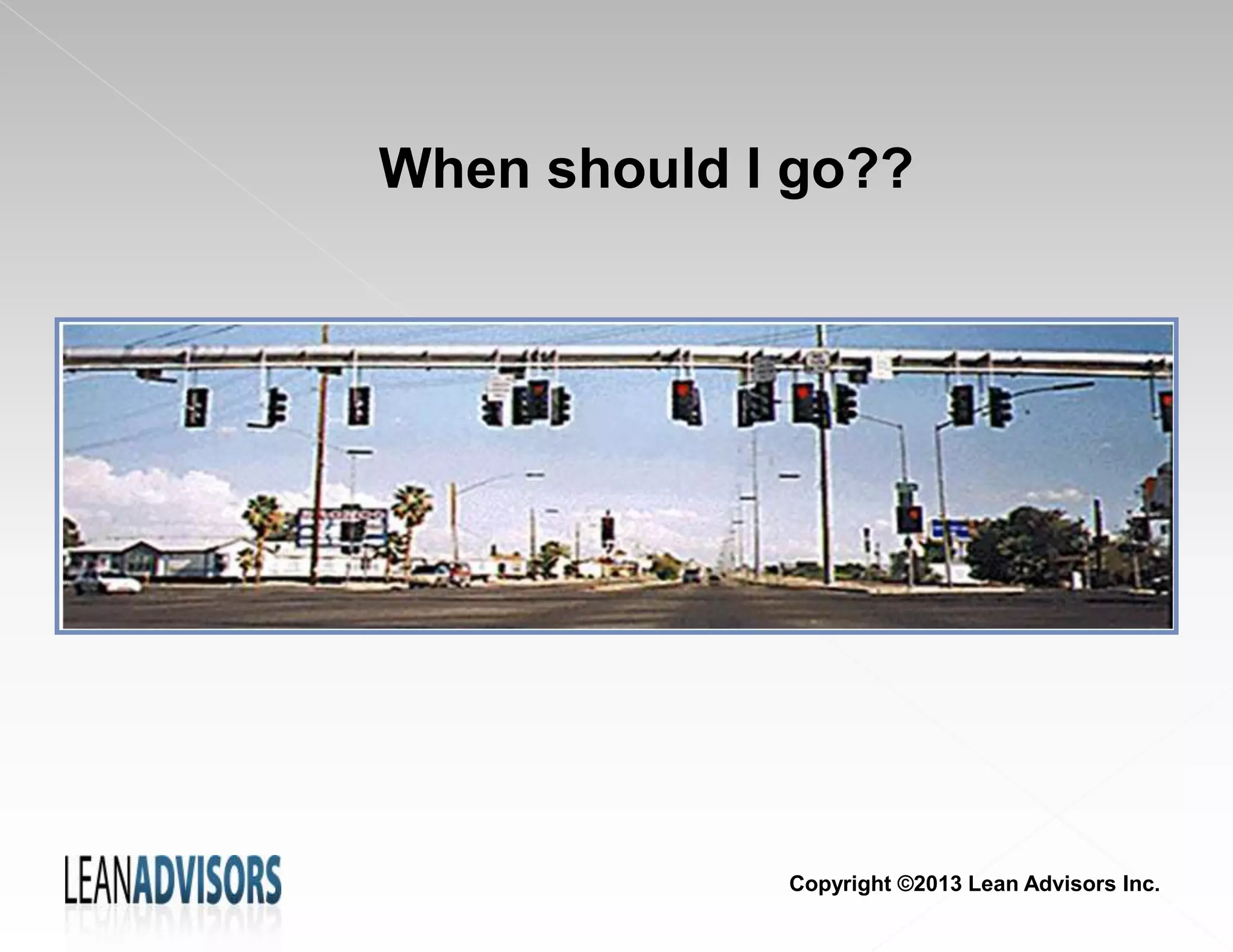

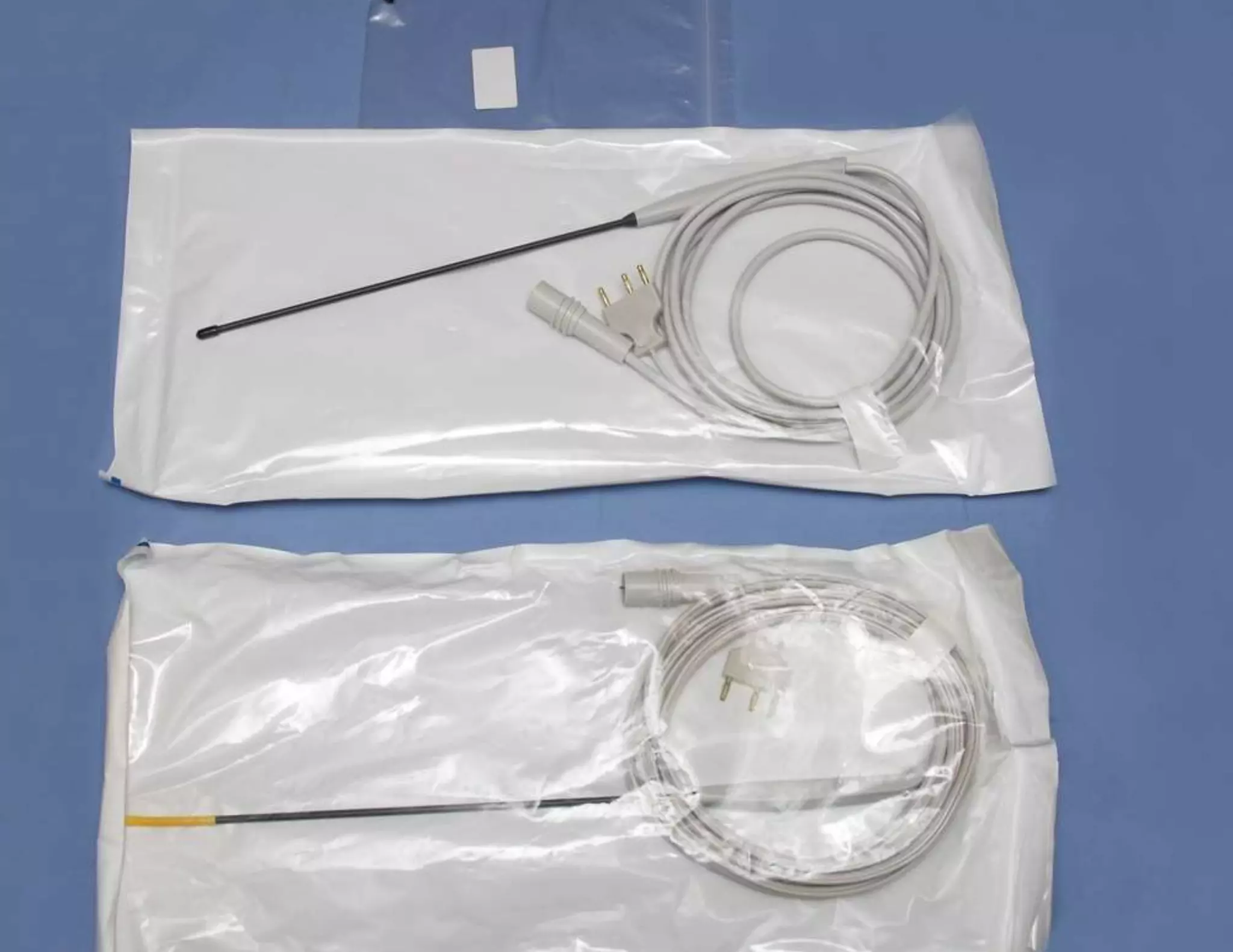

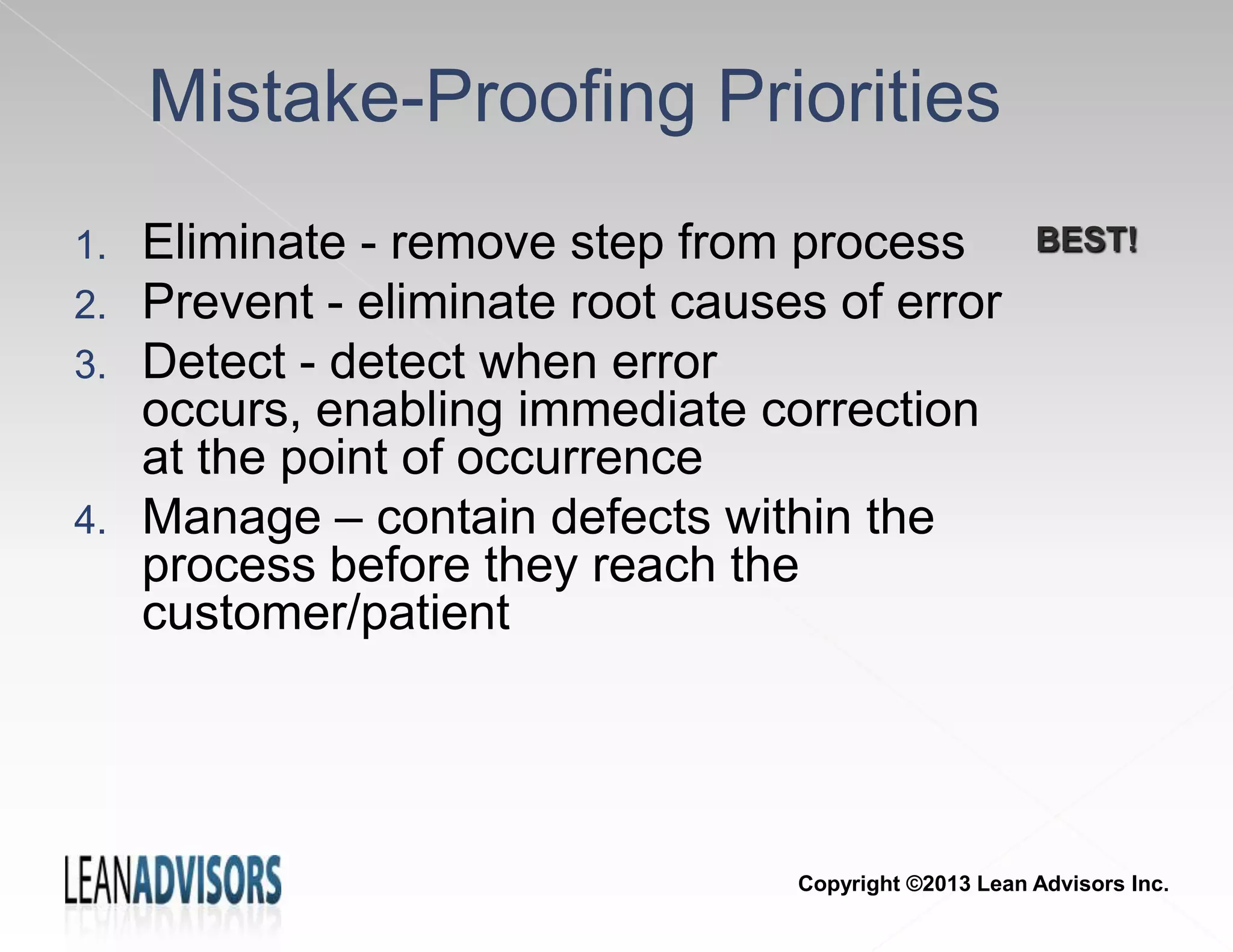

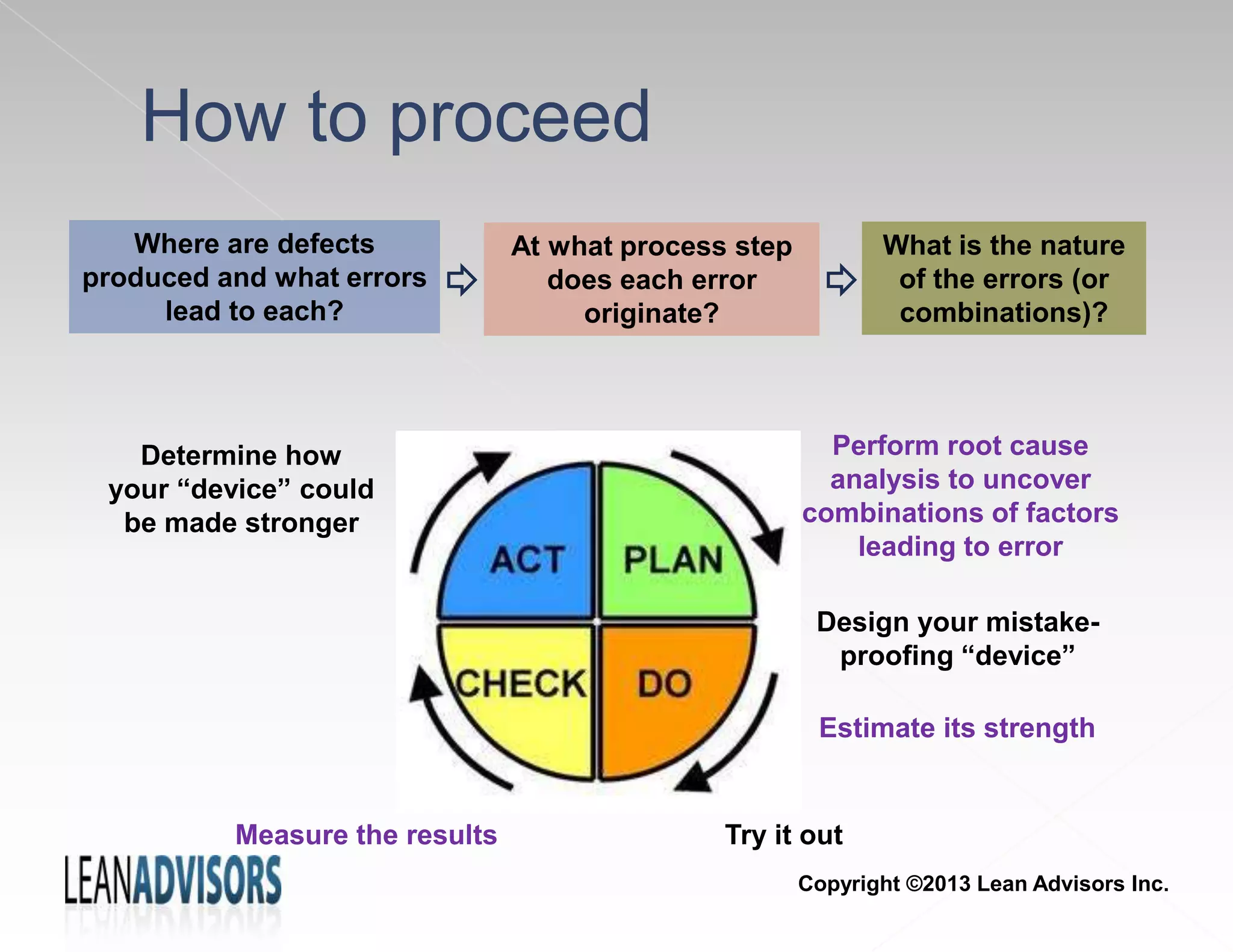

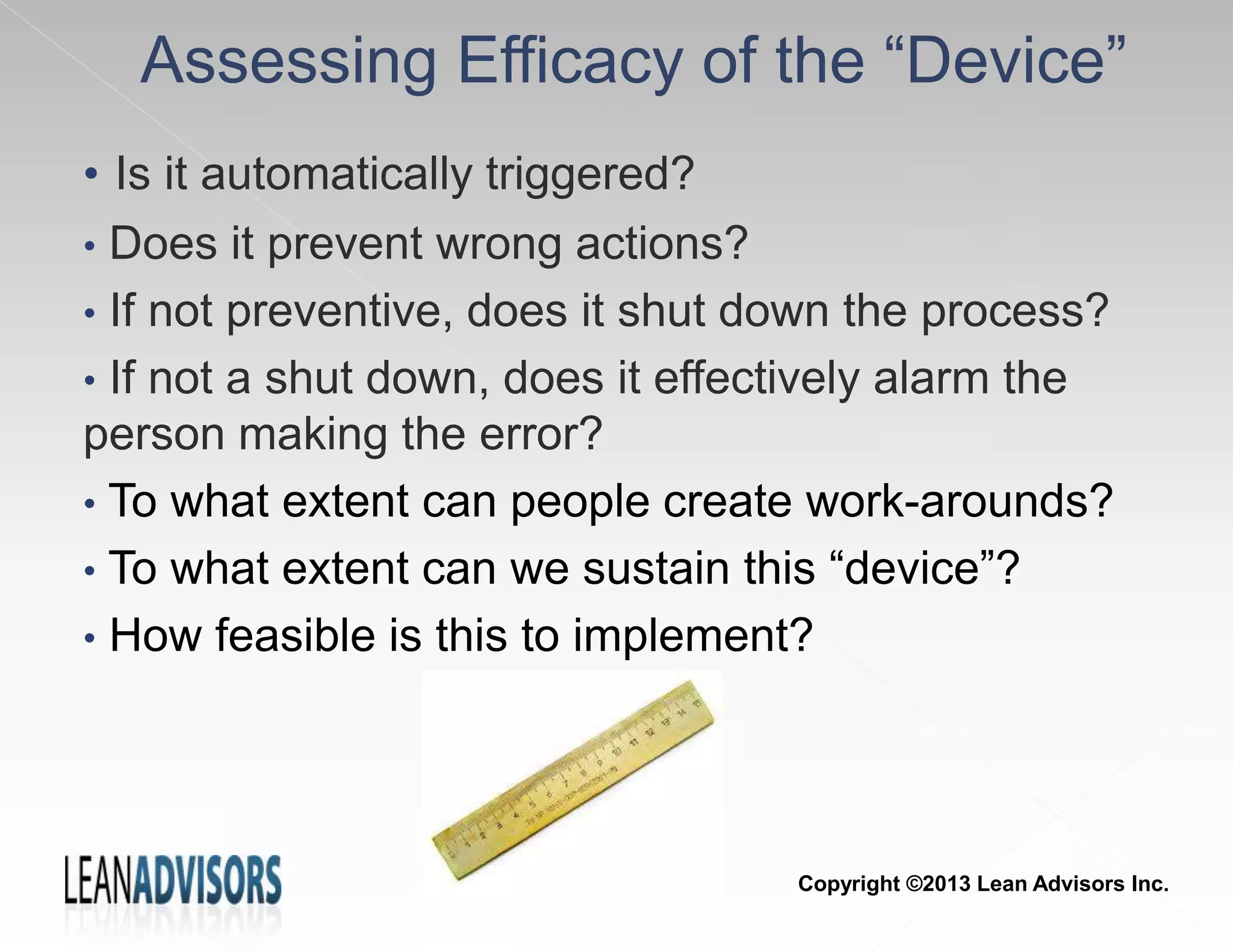

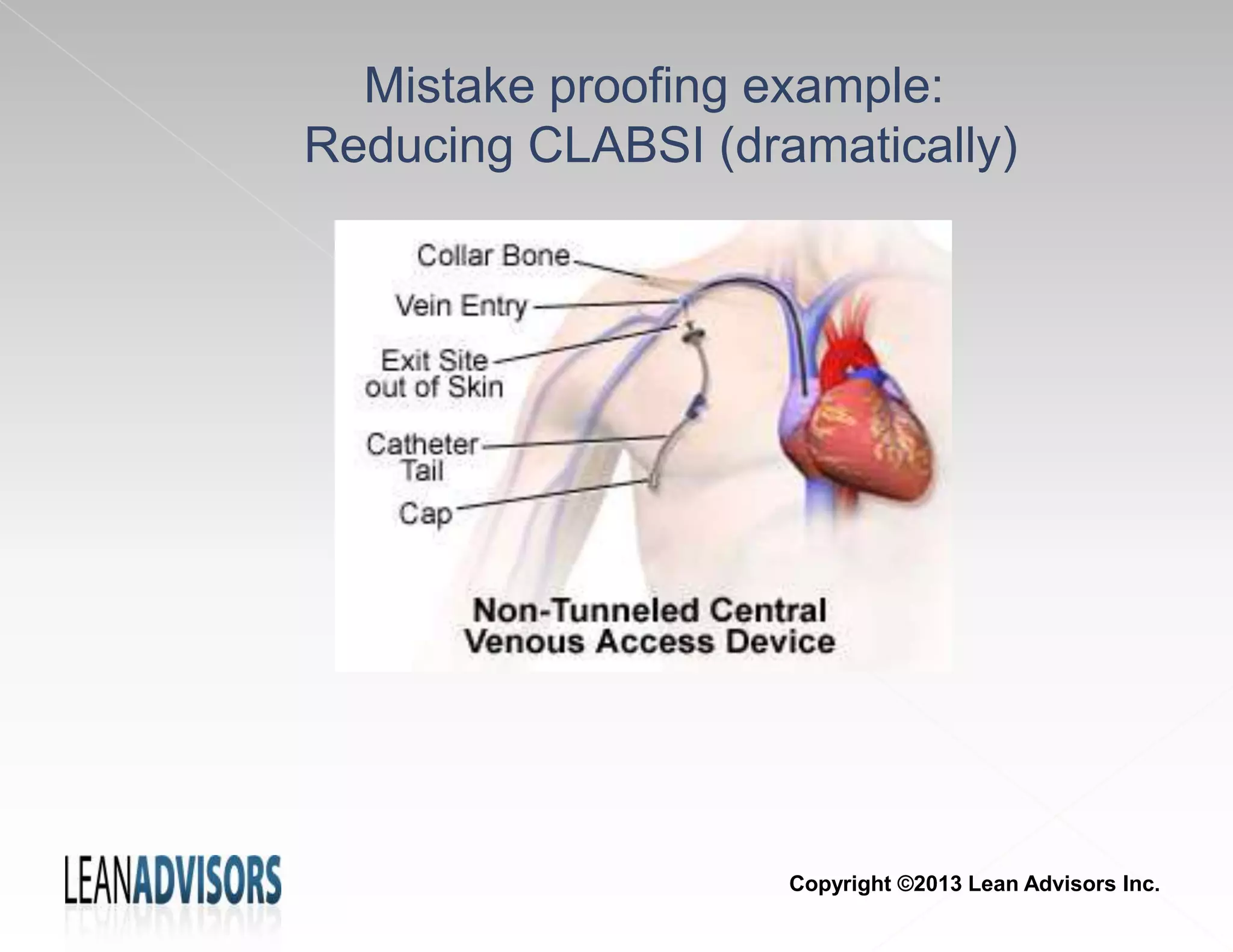

This document summarizes a presentation on effective mistake-proofing for healthcare. The presentation covers principles and techniques for sustained process improvement, including understanding why errors occur, defining mistake-proofing strategies, considering human factors, and developing solutions. Examples of mistake-proofing in healthcare are provided, as well as guidance on assessing the efficacy of mistake-proofing solutions. The goal of mistake-proofing is to design processes so that it is difficult to do the wrong thing and easy to do the right thing.